What is Global Ultra Fine Aluminium Hydroxide Market?

The Global Ultra Fine Aluminium Hydroxide Market refers to the industry focused on the production and distribution of ultra-fine aluminium hydroxide particles. These particles are characterized by their extremely small size, typically measured in micrometers (μm). Aluminium hydroxide is a versatile compound used in various applications due to its flame retardant properties, ability to act as a filler material, and its role as a catalyst carrier. The market for ultra-fine aluminium hydroxide is driven by the increasing demand for flame retardant materials in industries such as electronics, construction, and automotive. Additionally, the compound's use as a filler material in plastics, rubber, and other composites further fuels its market growth. The global market is expected to expand significantly in the coming years, driven by technological advancements and the growing need for high-performance materials in various industrial applications.

Below 1 μm, 1-1.5 μm, 1.5-3 μm in the Global Ultra Fine Aluminium Hydroxide Market:

In the Global Ultra Fine Aluminium Hydroxide Market, the particle size categories of Below 1 μm, 1-1.5 μm, and 1.5-3 μm play a crucial role in determining the specific applications and performance characteristics of the material. Particles Below 1 μm are highly sought after for their superior surface area and reactivity, making them ideal for applications requiring high levels of dispersion and uniformity. These ultra-fine particles are often used in advanced flame retardant systems, where their small size allows for better integration into polymer matrices, enhancing the material's overall flame retardant properties. Additionally, Below 1 μm particles are used in high-performance coatings and adhesives, where their fine size contributes to improved surface finish and mechanical properties. Particles in the 1-1.5 μm range strike a balance between performance and cost-effectiveness. This size range is commonly used in applications where moderate flame retardant properties are required, such as in certain types of plastics and rubber. The 1-1.5 μm particles offer good dispersion and integration into various matrices, making them suitable for a wide range of industrial applications. They are also used in the production of catalyst carriers, where their size and surface area provide an optimal balance for catalytic activity and stability. The 1.5-3 μm particle size range is typically used in applications where cost considerations are more critical, and ultra-fine particle size is not as crucial. These particles are often used as filler materials in construction materials, such as concrete and gypsum, where they help improve the material's mechanical properties and durability. The larger particle size in this range also makes them suitable for use in certain types of flame retardant systems, where they provide adequate performance at a lower cost compared to smaller particles. Overall, the different particle size categories in the Global Ultra Fine Aluminium Hydroxide Market cater to a wide range of applications, each with its specific performance requirements and cost considerations. The choice of particle size depends on the intended application, desired performance characteristics, and budget constraints, making it essential for manufacturers and end-users to carefully select the appropriate particle size for their specific needs.

Flame Retardant Material, Filling Material, Catalyst Carrier, Others in the Global Ultra Fine Aluminium Hydroxide Market:

The Global Ultra Fine Aluminium Hydroxide Market finds extensive usage in various applications, including flame retardant materials, filling materials, catalyst carriers, and other specialized uses. In the realm of flame retardant materials, ultra-fine aluminium hydroxide is highly valued for its ability to enhance the fire resistance of polymers and composites. When incorporated into materials such as plastics, rubber, and textiles, it acts as a flame retardant by releasing water vapor when exposed to high temperatures, thereby cooling the material and reducing the spread of flames. This makes it an essential component in the production of fire-resistant cables, electronic devices, and construction materials, where safety and compliance with fire regulations are paramount. As a filling material, ultra-fine aluminium hydroxide is used to improve the mechanical properties and durability of various composites. Its fine particle size allows for better dispersion within the matrix, resulting in enhanced strength, stiffness, and impact resistance. This makes it a popular choice in the production of high-performance plastics, rubber, and coatings, where it not only improves the material's physical properties but also contributes to cost savings by reducing the amount of expensive base material required. Additionally, its use as a filler material in construction products such as concrete and gypsum helps improve the overall performance and longevity of these materials. In the field of catalyst carriers, ultra-fine aluminium hydroxide plays a crucial role in supporting catalytic reactions. Its high surface area and chemical stability make it an ideal substrate for various catalytic processes, including those used in the petrochemical and automotive industries. By providing a stable and reactive surface, it enhances the efficiency and effectiveness of catalysts, leading to improved reaction rates and product yields. This makes it a valuable component in the production of catalysts used in processes such as hydrocracking, reforming, and emission control. Beyond these primary applications, ultra-fine aluminium hydroxide is also used in a variety of other specialized applications. For instance, it is employed in the production of advanced ceramics, where its fine particle size and purity contribute to the development of high-performance ceramic materials with superior thermal and mechanical properties. It is also used in the formulation of personal care products, such as toothpaste and deodorants, where its mild abrasive properties and chemical stability make it a suitable ingredient. Additionally, its use in water treatment processes helps in the removal of impurities and contaminants, contributing to the production of clean and safe drinking water. In summary, the Global Ultra Fine Aluminium Hydroxide Market serves a diverse range of applications, each benefiting from the unique properties of this versatile material. Whether used as a flame retardant, filling material, catalyst carrier, or in other specialized applications, ultra-fine aluminium hydroxide continues to play a vital role in enhancing the performance, safety, and efficiency of various products and processes across multiple industries.

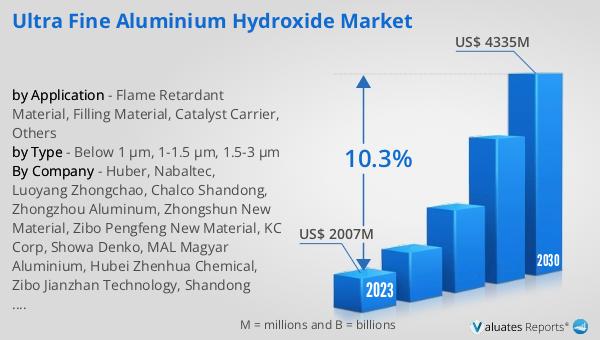

Global Ultra Fine Aluminium Hydroxide Market Outlook:

The global Ultra Fine Aluminium Hydroxide market is anticipated to expand from US$ 473 million in 2024 to US$ 644.4 million by 2030, reflecting a Compound Annual Growth Rate (CAGR) of 5.3% over the forecast period. Within this market, the product segment of 1.53 μm particles holds the largest share, accounting for over 55%. This significant market share underscores the importance of this particle size range in various industrial applications. The 1.53 μm particles offer a balanced combination of performance and cost-effectiveness, making them a preferred choice for many manufacturers and end-users. Their optimal size allows for good dispersion and integration into different matrices, enhancing the overall properties of the final product. As the demand for high-performance materials continues to grow across industries such as electronics, construction, and automotive, the market for ultra-fine aluminium hydroxide is expected to witness sustained growth. The increasing focus on safety and regulatory compliance, particularly in the use of flame retardant materials, further drives the demand for ultra-fine aluminium hydroxide. Overall, the market outlook for ultra-fine aluminium hydroxide remains positive, with steady growth anticipated in the coming years.

| Report Metric | Details |

| Report Name | Ultra Fine Aluminium Hydroxide Market |

| Accounted market size in 2024 | US$ 473 million |

| Forecasted market size in 2030 | US$ 644.4 million |

| CAGR | 5.3 |

| Base Year | 2024 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Sales by Region |

|

| By Company | Huber, Nabaltec, KC Group, Showa Denko, Sumitomo, Eti Aluminyum, R.J. Marshall, ZC-New Material, Chalco, Zibo Pengfeng New Material, Hubei Zhenhua Chemical, Shibang Chemical |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |