What is Global Twin-Screw Extruders for Food Market?

The global Twin-Screw Extruders for Food market is a specialized segment within the food processing industry that focuses on the use of twin-screw extruders to produce a variety of food products. Twin-screw extruders are advanced machines that use two intermeshing screws to mix, knead, and shape food ingredients into desired forms. These machines are highly versatile and can handle a wide range of raw materials, making them ideal for producing snacks, cereals, pet food, and other food items. The market for these extruders is driven by the increasing demand for processed and convenience foods, as well as the need for efficient and cost-effective food production methods. With advancements in technology, twin-screw extruders have become more efficient, offering better control over the texture, flavor, and nutritional content of the final product. This has led to their widespread adoption in the food industry, contributing to the growth of the global Twin-Screw Extruders for Food market.

Co-Rotating, Counter Rotating in the Global Twin-Screw Extruders for Food Market:

In the realm of twin-screw extruders, there are two primary types: co-rotating and counter-rotating. Co-rotating twin-screw extruders have screws that rotate in the same direction. This configuration is particularly effective for mixing and compounding processes because it provides a high level of shear and heat transfer. The co-rotating design allows for better homogenization of ingredients, making it ideal for producing consistent and high-quality food products. On the other hand, counter-rotating twin-screw extruders have screws that rotate in opposite directions. This setup is beneficial for processes that require gentle mixing and minimal shear, such as the production of delicate food items or those with sensitive ingredients. Counter-rotating extruders are often used in applications where maintaining the integrity of the ingredients is crucial. Both types of extruders offer unique advantages and are chosen based on the specific requirements of the food production process. The choice between co-rotating and counter-rotating extruders depends on factors such as the type of food being produced, the desired texture and consistency, and the sensitivity of the ingredients. As the global Twin-Screw Extruders for Food market continues to grow, manufacturers are investing in research and development to enhance the capabilities of both co-rotating and counter-rotating extruders, ensuring they meet the evolving needs of the food industry.

Human Food, Pet Food in the Global Twin-Screw Extruders for Food Market:

Twin-screw extruders are widely used in the production of both human food and pet food, thanks to their versatility and efficiency. In the human food sector, these machines are employed to produce a variety of products, including snacks, breakfast cereals, pasta, and meat analogs. The ability of twin-screw extruders to handle different types of raw materials and produce consistent, high-quality products makes them invaluable in this sector. For instance, in the production of snacks, twin-screw extruders can mix and shape ingredients into various forms, such as chips, puffs, and sticks, while ensuring uniform texture and flavor. Similarly, in the production of breakfast cereals, these machines can process grains and other ingredients to create a wide range of cereal shapes and sizes. In the pet food sector, twin-screw extruders are used to produce dry kibble, treats, and other pet food products. The precise control over the extrusion process allows manufacturers to create pet food with specific nutritional profiles, textures, and flavors that meet the dietary needs and preferences of different pets. Additionally, the ability to incorporate various ingredients, such as meat, vegetables, and grains, into the extrusion process ensures that pet food products are both nutritious and appealing to pets. Overall, the use of twin-screw extruders in the food industry, both for human and pet food, highlights their importance in modern food production, offering efficiency, versatility, and high-quality output.

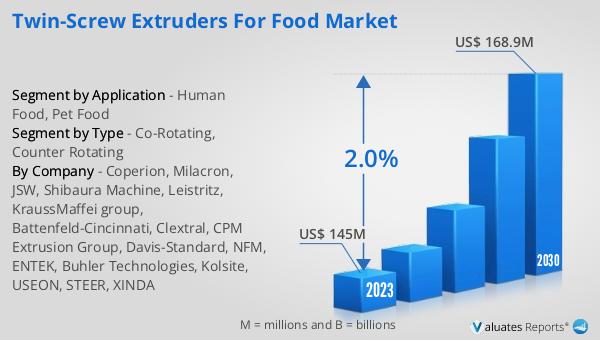

Global Twin-Screw Extruders for Food Market Outlook:

The global Twin-Screw Extruders for Food market was valued at US$ 145 million in 2023 and is anticipated to reach US$ 168.9 million by 2030, witnessing a CAGR of 2.0% during the forecast period 2024-2030. This market outlook indicates a steady growth trajectory for twin-screw extruders in the food industry. The increasing demand for processed and convenience foods, coupled with advancements in extrusion technology, is driving this growth. Twin-screw extruders offer numerous benefits, including improved efficiency, better control over product quality, and the ability to handle a wide range of raw materials. These advantages make them a preferred choice for food manufacturers looking to enhance their production capabilities and meet the evolving demands of consumers. As the market continues to expand, manufacturers are likely to invest in further research and development to improve the performance and versatility of twin-screw extruders, ensuring they remain at the forefront of food processing technology.

| Report Metric | Details |

| Report Name | Twin-Screw Extruders for Food Market |

| Accounted market size in 2023 | US$ 145 million |

| Forecasted market size in 2030 | US$ 168.9 million |

| CAGR | 2.0% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Coperion, Milacron, JSW, Shibaura Machine, Leistritz, KraussMaffei group, Battenfeld-Cincinnati, Clextral, CPM Extrusion Group, Davis-Standard, NFM, ENTEK, Buhler Technologies, Kolsite, USEON, STEER, XINDA |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |