What is Global Thermal Copper Pillar Bump Market?

The Global Thermal Copper Pillar Bump Market is a specialized segment within the semiconductor industry that focuses on the use of copper pillars for interconnects in integrated circuits (ICs). These copper pillars, often referred to as "bumps," are tiny columns of copper that serve as electrical connections between different layers of a semiconductor device. They are crucial for ensuring efficient electrical performance and thermal management in advanced electronic devices. The market for thermal copper pillar bumps is driven by the increasing demand for high-performance electronic devices, such as smartphones, tablets, and other consumer electronics, which require advanced packaging solutions to enhance their functionality and reliability. Additionally, the growing adoption of copper pillar technology in various industries, including automotive, industrial equipment, and aerospace, further fuels the market's growth. The use of copper pillars offers several advantages, such as improved electrical conductivity, better heat dissipation, and enhanced mechanical stability, making them a preferred choice for modern semiconductor packaging. As technology continues to advance, the Global Thermal Copper Pillar Bump Market is expected to witness significant growth, driven by the need for more efficient and reliable electronic devices.

Standard Cu Pillar, Fine Pitch Cu Pillar, Micro-Bumps, Others in the Global Thermal Copper Pillar Bump Market:

Standard Cu Pillar, Fine Pitch Cu Pillar, Micro-Bumps, and Others are different types of copper pillar bumps used in the Global Thermal Copper Pillar Bump Market, each serving specific applications and requirements. Standard Cu Pillar refers to the conventional copper pillars used in semiconductor packaging, typically characterized by their larger size and higher current-carrying capacity. These are commonly used in applications where robust electrical and thermal performance is required, such as in power devices and high-performance computing. Fine Pitch Cu Pillar, on the other hand, refers to copper pillars with a smaller pitch, meaning the distance between adjacent pillars is reduced. This allows for higher interconnect density, making them suitable for applications where space is a constraint, such as in mobile devices and compact electronic gadgets. Micro-Bumps are even smaller than fine pitch pillars and are used in advanced packaging technologies like 3D ICs (integrated circuits) and system-in-package (SiP) solutions. They enable the stacking of multiple semiconductor dies, leading to increased functionality and performance in a smaller footprint. The "Others" category includes various specialized copper pillar technologies that cater to niche applications or specific industry requirements. For instance, some copper pillars are designed with unique shapes or materials to enhance their performance in specific environments, such as high-temperature or high-vibration conditions. The choice of copper pillar type depends on several factors, including the application's electrical, thermal, and mechanical requirements, as well as the overall design and manufacturing considerations. Each type of copper pillar offers distinct advantages and trade-offs, making it essential for manufacturers to carefully select the appropriate technology for their specific needs. As the demand for more advanced and compact electronic devices continues to grow, the development and adoption of these different types of copper pillar bumps are expected to play a crucial role in the evolution of semiconductor packaging technologies.

Consumer Electronics, Automobile, Industrial Equipment, Medical Insurance, Military and Defense, Aeronautics and Astronautics, Telecom in the Global Thermal Copper Pillar Bump Market:

The Global Thermal Copper Pillar Bump Market finds extensive usage across various industries, including consumer electronics, automobiles, industrial equipment, medical insurance, military and defense, aeronautics and astronautics, and telecom. In consumer electronics, copper pillar bumps are essential for enhancing the performance and reliability of devices such as smartphones, tablets, laptops, and wearable gadgets. They enable the miniaturization of components while ensuring efficient electrical and thermal management, which is crucial for the high-speed processing and extended battery life of modern electronic devices. In the automotive industry, copper pillar bumps are used in advanced driver-assistance systems (ADAS), infotainment systems, and electric vehicle (EV) power electronics. They help improve the performance and reliability of these systems, which are critical for the safety and efficiency of modern vehicles. Industrial equipment, such as robotics, automation systems, and heavy machinery, also benefit from the use of copper pillar bumps. These components enhance the durability and performance of industrial electronics, ensuring reliable operation in harsh environments. In the medical insurance sector, copper pillar bumps are used in medical devices and diagnostic equipment, where precision and reliability are paramount. They enable the development of compact and high-performance medical electronics, which are essential for accurate diagnostics and patient monitoring. The military and defense industry relies on copper pillar bumps for advanced communication systems, radar, and other critical electronic components. These components must withstand extreme conditions and provide reliable performance, making copper pillar technology an ideal choice. In aeronautics and astronautics, copper pillar bumps are used in avionics, satellite systems, and other aerospace electronics. They ensure the reliability and performance of these systems, which are crucial for the safety and success of aerospace missions. Lastly, in the telecom industry, copper pillar bumps are used in network infrastructure, including base stations, routers, and switches. They help improve the performance and reliability of telecom equipment, ensuring efficient data transmission and communication. Overall, the Global Thermal Copper Pillar Bump Market plays a vital role in enhancing the performance, reliability, and miniaturization of electronic devices across various industries, driving innovation and technological advancements.

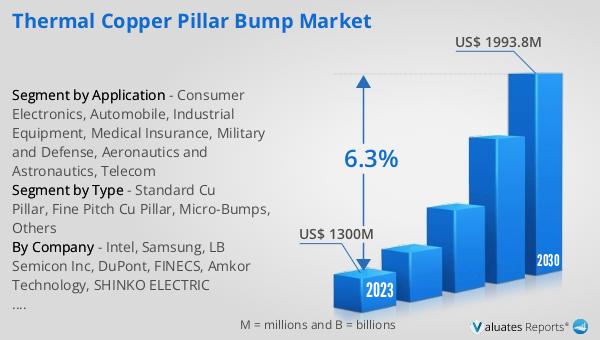

Global Thermal Copper Pillar Bump Market Outlook:

The global Thermal Copper Pillar Bump market was valued at US$ 1300 million in 2023 and is anticipated to reach US$ 1993.8 million by 2030, witnessing a CAGR of 6.3% during the forecast period 2024-2030. This market growth reflects the increasing demand for advanced semiconductor packaging solutions that offer improved electrical performance, thermal management, and mechanical stability. The adoption of copper pillar technology is driven by the need for more efficient and reliable electronic devices across various industries, including consumer electronics, automotive, industrial equipment, medical devices, military and defense, aerospace, and telecommunications. As electronic devices continue to evolve, the demand for high-performance interconnects like thermal copper pillar bumps is expected to rise, contributing to the market's growth. The market's expansion is also supported by ongoing advancements in semiconductor manufacturing technologies, which enable the production of smaller, more efficient, and higher-performing copper pillar bumps. These advancements are crucial for meeting the increasing performance and miniaturization requirements of modern electronic devices. Overall, the Global Thermal Copper Pillar Bump Market is poised for significant growth, driven by the continuous demand for advanced packaging solutions and the ongoing technological advancements in the semiconductor industry.

| Report Metric | Details |

| Report Name | Thermal Copper Pillar Bump Market |

| Accounted market size in 2023 | US$ 1300 million |

| Forecasted market size in 2030 | US$ 1993.8 million |

| CAGR | 6.3% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Intel, Samsung, LB Semicon Inc, DuPont, FINECS, Amkor Technology, SHINKO ELECTRIC INDUSTRIES CO.,LTD., ASE, Raytek Semiconductor,Inc., Sigurd Microelectronics Corporation, Nepes, SJ Group Co Ltd, ChipMOS TECHNOLOGIES, Element Solutions, Jiangsu Changjiang Electronics Tech Co |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |