What is Global Sealants for Military Vehicles Market?

The Global Sealants for Military Vehicles Market refers to the industry focused on producing and supplying sealants specifically designed for military vehicles. These sealants are essential for maintaining the integrity and performance of military vehicles, which operate in some of the most demanding environments. They help in protecting the vehicles from harsh weather conditions, chemical exposures, and physical damages. The market encompasses a variety of sealant types, each tailored to meet specific requirements of different military vehicles, whether they are combat or non-combat vehicles. The demand for these sealants is driven by the need for enhanced durability, reliability, and longevity of military vehicles, ensuring they remain operational and effective in various missions and terrains. The market is influenced by advancements in sealant technologies, increasing defense budgets, and the ongoing need for military modernization across the globe.

Polysulfide Sealants, Silicone Sealants, Others in the Global Sealants for Military Vehicles Market:

Polysulfide sealants, silicone sealants, and other types of sealants play crucial roles in the Global Sealants for Military Vehicles Market. Polysulfide sealants are known for their excellent chemical resistance and flexibility, making them ideal for sealing fuel tanks, hydraulic systems, and other components exposed to harsh chemicals and fuels. They provide a durable and long-lasting seal that can withstand extreme temperatures and pressures, ensuring the safety and reliability of military vehicles. Silicone sealants, on the other hand, are valued for their superior thermal stability and resistance to weathering, UV radiation, and moisture. These properties make silicone sealants suitable for sealing windows, doors, and other exterior parts of military vehicles, protecting them from environmental damage and ensuring their structural integrity. Other types of sealants used in military vehicles include polyurethane sealants, which offer a good balance of flexibility, adhesion, and durability, and epoxy sealants, known for their high strength and resistance to mechanical stress. Each type of sealant is selected based on the specific requirements of the application, ensuring optimal performance and protection for military vehicles in various operational conditions. The choice of sealant also depends on factors such as the material of the vehicle components, the type of exposure they will face, and the desired lifespan of the seal. The development and use of advanced sealants in military vehicles are driven by the need to enhance their operational readiness, reduce maintenance costs, and extend their service life. As military vehicles continue to evolve with new technologies and materials, the demand for specialized sealants that can meet these changing requirements is expected to grow.

Combat Vehicle, Non-combat Vehicle in the Global Sealants for Military Vehicles Market:

The usage of sealants in the Global Sealants for Military Vehicles Market can be broadly categorized into combat vehicles and non-combat vehicles. Combat vehicles, such as tanks, armored personnel carriers, and infantry fighting vehicles, operate in highly demanding environments where they are exposed to extreme conditions, including high temperatures, mechanical stress, and chemical attacks. Sealants used in combat vehicles must provide robust protection against these harsh conditions, ensuring the vehicles remain operational and effective in combat situations. For instance, polysulfide sealants are often used in fuel tanks and hydraulic systems of combat vehicles to prevent leaks and ensure the safe operation of these critical systems. Silicone sealants are used to seal windows, doors, and other exterior parts, protecting them from environmental damage and maintaining the vehicle's structural integrity. Non-combat vehicles, such as transport trucks, medical vehicles, and command and control vehicles, also require reliable sealants to ensure their functionality and durability. While these vehicles may not face the same level of stress as combat vehicles, they still operate in challenging environments and need protection against weathering, moisture, and mechanical wear. Sealants used in non-combat vehicles help to maintain the integrity of the vehicle's structure, prevent leaks, and protect sensitive equipment from environmental damage. The use of advanced sealants in both combat and non-combat vehicles is essential for maintaining their operational readiness, reducing maintenance costs, and extending their service life. As military operations become more complex and demanding, the need for specialized sealants that can meet the unique requirements of different types of military vehicles is expected to increase.

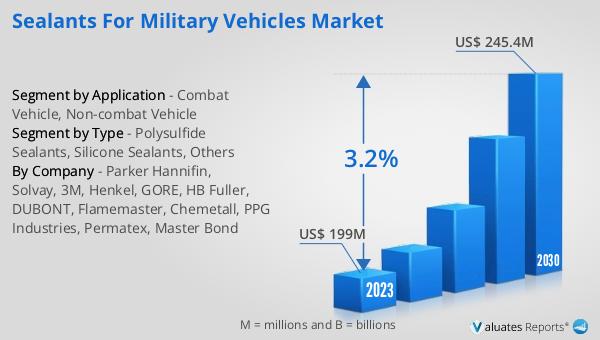

Global Sealants for Military Vehicles Market Outlook:

The global Sealants for Military Vehicles market was valued at US$ 199 million in 2023 and is anticipated to reach US$ 245.4 million by 2030, witnessing a CAGR of 3.2% during the forecast period 2024-2030. This growth reflects the increasing demand for advanced sealants that can enhance the durability, reliability, and performance of military vehicles. The market's expansion is driven by factors such as rising defense budgets, ongoing military modernization programs, and the need for vehicles that can withstand extreme operational conditions. The development of new sealant technologies and materials also contributes to the market's growth, offering improved performance and protection for military vehicles. As military forces around the world continue to invest in upgrading their vehicle fleets, the demand for high-quality sealants is expected to rise, supporting the market's positive outlook.

| Report Metric | Details |

| Report Name | Sealants for Military Vehicles Market |

| Accounted market size in 2023 | US$ 199 million |

| Forecasted market size in 2030 | US$ 245.4 million |

| CAGR | 3.2% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Parker Hannifin, Solvay, 3M, Henkel, GORE, HB Fuller, DUBONT, Flamemaster, Chemetall, PPG Industries, Permatex, Master Bond |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |