What is Global Rotary Table Blast Machine Market?

The Global Rotary Table Blast Machine Market refers to the worldwide industry focused on the production, distribution, and utilization of rotary table blast machines. These machines are specialized equipment used for surface treatment processes such as cleaning, deburring, descaling, decoring, and peening of various products. The rotary table blast machine operates by rotating the workpiece on a table while blasting media is propelled against its surface to achieve the desired finish. This market encompasses a wide range of industries including automotive, aerospace, shipbuilding, and others, where surface treatment is a critical part of the manufacturing process. The demand for these machines is driven by the need for efficient and cost-effective solutions to enhance product quality and durability. The market is characterized by technological advancements, increasing automation, and the development of more efficient and environmentally friendly blasting media. As industries continue to seek ways to improve their manufacturing processes, the global rotary table blast machine market is expected to grow, offering innovative solutions to meet the evolving needs of various sectors.

Single-table, Multi-table in the Global Rotary Table Blast Machine Market:

In the Global Rotary Table Blast Machine Market, there are two primary types of machines: single-table and multi-table. Single-table rotary blast machines are designed with a single rotating table where the workpieces are placed for surface treatment. These machines are typically used for smaller batch sizes and are ideal for applications where precision and consistency are crucial. The single-table design allows for easy loading and unloading of workpieces, making it suitable for industries that require frequent changeovers and high flexibility. On the other hand, multi-table rotary blast machines feature multiple rotating tables, which can operate simultaneously or sequentially. This design significantly increases the throughput and efficiency of the blasting process, making it suitable for high-volume production environments. Multi-table machines are often used in industries where large quantities of workpieces need to be processed quickly and consistently. The choice between single-table and multi-table machines depends on various factors such as production volume, workpiece size, and the specific requirements of the surface treatment process. Both types of machines offer unique advantages and can be customized to meet the specific needs of different industries. The global market for these machines is driven by the increasing demand for efficient and cost-effective surface treatment solutions across various sectors. As industries continue to evolve and seek ways to improve their manufacturing processes, the demand for both single-table and multi-table rotary blast machines is expected to grow, offering innovative solutions to meet the diverse needs of the market.

Automotive, Aerospace, Shipbuilding, Others in the Global Rotary Table Blast Machine Market:

The Global Rotary Table Blast Machine Market finds extensive usage in various industries, including automotive, aerospace, shipbuilding, and others. In the automotive industry, these machines are used for cleaning, deburring, and peening of engine components, transmission parts, and other critical components to enhance their performance and durability. The precise and consistent surface treatment provided by rotary table blast machines ensures that automotive parts meet stringent quality standards and perform reliably under demanding conditions. In the aerospace industry, rotary table blast machines are used for surface treatment of aircraft components such as turbine blades, landing gear, and structural parts. The high precision and consistency of these machines are crucial for ensuring the safety and reliability of aerospace components, which operate under extreme conditions. In the shipbuilding industry, rotary table blast machines are used for cleaning and descaling of large metal structures, such as hulls and decks, to prepare them for painting and coating. The efficient surface treatment provided by these machines helps to prevent corrosion and extend the lifespan of ships. Other industries that utilize rotary table blast machines include construction, medical device manufacturing, and general manufacturing. In these industries, the machines are used for various surface treatment applications, such as cleaning, deburring, and peening, to improve the quality and performance of products. The versatility and efficiency of rotary table blast machines make them an essential tool in various manufacturing processes, driving their demand across different sectors.

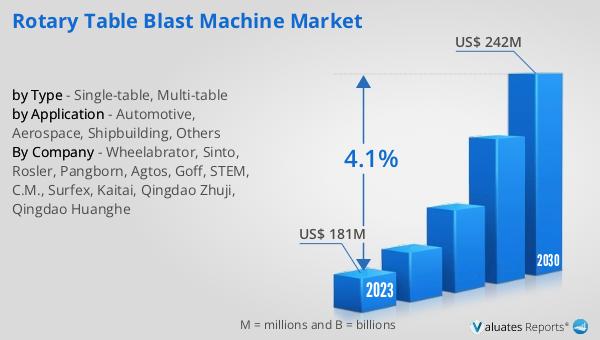

Global Rotary Table Blast Machine Market Outlook:

Rotary table blast machines offer a cost-effective solution for batch cleaning, deburring, descaling, decoring, and peening a wide variety of products. The global Rotary Table Blast Machine market was valued at US$ 181 million in 2023 and is anticipated to reach US$ 242 million by 2030, witnessing a CAGR of 4.1% during the forecast period from 2024 to 2030. These machines are designed to provide efficient and consistent surface treatment, which is essential for enhancing the quality and durability of products across various industries. The cost-effectiveness of rotary table blast machines lies in their ability to process multiple workpieces simultaneously, reducing the time and labor required for surface treatment. Additionally, the use of advanced blasting media and automation technologies further enhances the efficiency and effectiveness of these machines. As industries continue to seek ways to improve their manufacturing processes and reduce costs, the demand for rotary table blast machines is expected to grow. The market outlook for these machines is positive, with increasing adoption across various sectors driven by the need for high-quality surface treatment solutions. The growth of the global Rotary Table Blast Machine market is also supported by technological advancements and the development of more efficient and environmentally friendly blasting media. As a result, rotary table blast machines are becoming an increasingly important tool in the manufacturing processes of various industries, offering innovative solutions to meet the evolving needs of the market.

| Report Metric | Details |

| Report Name | Rotary Table Blast Machine Market |

| Accounted market size in 2023 | US$ 181 million |

| Forecasted market size in 2030 | US$ 242 million |

| CAGR | 4.1% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Wheelabrator, Sinto, Rosler, Pangborn, Agtos, Goff, STEM, C.M., Surfex, Kaitai, Qingdao Zhuji, Qingdao Huanghe |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |