What is Global Radar Level Transmitters Market?

The Global Radar Level Transmitters Market refers to the worldwide industry focused on the production, distribution, and application of radar level transmitters. These devices are essential for measuring the level of liquids, solids, or slurries within various containers, tanks, or silos. Radar level transmitters utilize radar technology to provide accurate and reliable measurements, which are crucial for maintaining operational efficiency and safety in numerous industries. The market encompasses a wide range of products, including both non-contact and guided wave radar level transmitters, each designed to meet specific needs and conditions. The growth of this market is driven by the increasing demand for automation and precision in industries such as oil and gas, pharmaceuticals, power generation, chemicals, and food and beverage. As industries continue to evolve and prioritize efficiency and safety, the demand for advanced radar level measurement solutions is expected to rise, making the Global Radar Level Transmitters Market a vital component of modern industrial operations.

Non-contact Radar Level Transmitter, Guided Wave Radar Level Transmitter in the Global Radar Level Transmitters Market:

Non-contact Radar Level Transmitters and Guided Wave Radar Level Transmitters are two primary types of radar level measurement devices used in the Global Radar Level Transmitters Market. Non-contact radar level transmitters operate by emitting microwave radar signals towards the surface of the material being measured. These signals are then reflected back to the transmitter, where the time delay between emission and reception is used to calculate the level of the material. This type of transmitter is particularly advantageous in applications where the material being measured is corrosive, sticky, or has a tendency to build up on the sensor, as there is no direct contact between the transmitter and the material. Non-contact radar level transmitters are widely used in industries such as oil and gas, chemicals, and food and beverage, where maintaining the integrity of the material and the sensor is crucial. On the other hand, Guided Wave Radar (GWR) Level Transmitters use a different approach. These devices send microwave radar signals down a probe or a waveguide that is immersed in the material being measured. The signals travel down the probe and are reflected back when they encounter the surface of the material. The time delay between the emission and reception of the signals is then used to determine the level of the material. Guided Wave Radar Level Transmitters are highly accurate and reliable, even in challenging conditions such as high temperatures, high pressures, and varying dielectric constants. They are particularly useful in applications where precise level measurement is critical, such as in the pharmaceutical and biotech industries, power generation, and chemical processing. Both types of radar level transmitters offer unique advantages and are chosen based on the specific requirements of the application. Non-contact radar level transmitters are ideal for applications where the material being measured is aggressive or where there is a risk of build-up on the sensor. They provide accurate measurements without the need for maintenance or cleaning, making them a cost-effective solution for many industries. Guided Wave Radar Level Transmitters, on the other hand, offer superior accuracy and reliability in challenging conditions. They are capable of measuring levels in both liquids and solids, making them versatile and suitable for a wide range of applications. In the Global Radar Level Transmitters Market, the choice between non-contact and guided wave radar level transmitters depends on factors such as the nature of the material being measured, the environmental conditions, and the required level of accuracy. Both types of transmitters play a crucial role in ensuring the efficient and safe operation of industrial processes. As industries continue to seek advanced solutions for level measurement, the demand for both non-contact and guided wave radar level transmitters is expected to grow, driving innovation and development in the Global Radar Level Transmitters Market.

Oil and Gas, Pharmaceutical and Biotech, Power Generation, Chemical, Food and Beverage, Other in the Global Radar Level Transmitters Market:

The usage of Global Radar Level Transmitters Market spans across various industries, each with its unique requirements and challenges. In the oil and gas industry, radar level transmitters are essential for monitoring the levels of crude oil, refined products, and other fluids in storage tanks and pipelines. Accurate level measurement is crucial for optimizing production, ensuring safety, and preventing overflows or leaks. Non-contact radar level transmitters are particularly useful in this industry due to their ability to provide reliable measurements without being affected by the corrosive nature of the fluids or the presence of vapors and gases. In the pharmaceutical and biotech industries, precision and reliability are paramount. Radar level transmitters are used to measure the levels of various liquids and powders in reactors, storage tanks, and other process vessels. Guided Wave Radar Level Transmitters are often preferred in these applications due to their high accuracy and ability to perform well in challenging conditions such as high temperatures and pressures. These transmitters help ensure that the production processes are carried out efficiently and that the final products meet the required quality standards. The power generation industry also relies heavily on radar level transmitters for monitoring the levels of water, steam, and other fluids in boilers, condensers, and storage tanks. Accurate level measurement is essential for maintaining the efficiency and safety of power plants. Both non-contact and guided wave radar level transmitters are used in this industry, depending on the specific application and environmental conditions. For example, non-contact radar level transmitters are often used in applications where the fluid is highly corrosive or where there is a risk of build-up on the sensor, while guided wave radar level transmitters are used in applications that require high accuracy and reliability. In the chemical industry, radar level transmitters are used to measure the levels of various chemicals and solvents in storage tanks, reactors, and other process vessels. The aggressive nature of many chemicals makes non-contact radar level transmitters an ideal choice, as they can provide accurate measurements without being affected by the corrosive properties of the chemicals. Guided Wave Radar Level Transmitters are also used in this industry, particularly in applications that require precise level measurement and where the environmental conditions are challenging. The food and beverage industry also benefits from the use of radar level transmitters. These devices are used to measure the levels of various liquids, powders, and solids in storage tanks, silos, and other process vessels. Non-contact radar level transmitters are often preferred in this industry due to their ability to provide accurate measurements without coming into contact with the material being measured, which helps maintain the hygiene and quality of the products. Guided Wave Radar Level Transmitters are also used in applications that require high accuracy and reliability, such as in the measurement of ingredients in the production process. Other industries that use radar level transmitters include water and wastewater treatment, mining, and pulp and paper. In water and wastewater treatment, radar level transmitters are used to monitor the levels of water, sludge, and other fluids in storage tanks and treatment vessels. In the mining industry, these devices are used to measure the levels of various materials in storage silos and process vessels. In the pulp and paper industry, radar level transmitters are used to monitor the levels of pulp, chemicals, and other materials in storage tanks and process vessels. Overall, the usage of radar level transmitters in various industries highlights their importance in ensuring the efficient and safe operation of industrial processes. As industries continue to evolve and seek advanced solutions for level measurement, the demand for radar level transmitters is expected to grow, driving innovation and development in the Global Radar Level Transmitters Market.

Global Radar Level Transmitters Market Outlook:

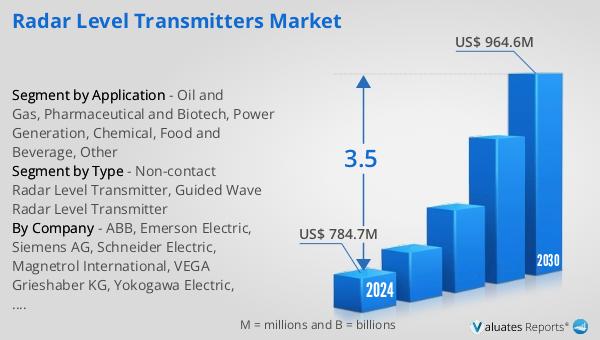

The global Radar Level Transmitters market is anticipated to expand from US$ 784.7 million in 2024 to US$ 964.6 million by 2030, reflecting a Compound Annual Growth Rate (CAGR) of 3.5% during the forecast period. The top five manufacturers globally hold a significant share, exceeding 40% of the market. North America stands as the largest market, accounting for over 30% of the total share, followed by Europe and the Asia-Pacific region, which together represent approximately 55% of the market. This growth is driven by the increasing demand for accurate and reliable level measurement solutions across various industries, including oil and gas, pharmaceuticals, power generation, chemicals, and food and beverage. The advancements in radar technology and the growing emphasis on automation and precision in industrial processes are also contributing to the market's expansion. As industries continue to prioritize efficiency and safety, the demand for advanced radar level transmitters is expected to rise, further propelling the growth of the Global Radar Level Transmitters Market.

| Report Metric | Details |

| Report Name | Radar Level Transmitters Market |

| Accounted market size in 2024 | US$ 784.7 million |

| Forecasted market size in 2030 | US$ 964.6 million |

| CAGR | 3.5 |

| Base Year | 2024 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Sales by Region |

|

| By Company | ABB, Emerson Electric, Siemens AG, Schneider Electric, Magnetrol International, VEGA Grieshaber KG, Yokogawa Electric, OMEGA Engineering, Honeywell, KROHNE, Matsushima Measure Tech Co., Ltd., Dandong Top Electronics Instrument Group Co. Ltd, E+H |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |