What is Global Portable Welding Fume Extractor Market?

The Global Portable Welding Fume Extractor Market refers to the industry focused on the production and distribution of portable devices designed to extract and filter harmful fumes generated during welding processes. These devices are essential for maintaining a safe and healthy working environment, as welding fumes can contain hazardous substances like metal oxides, silicates, and fluorides. The market encompasses a wide range of products, including various sizes and types of fume extractors, each tailored to different welding applications and environments. The demand for portable welding fume extractors is driven by stringent occupational safety regulations, increasing awareness about the health risks associated with welding fumes, and the growing adoption of welding activities across various industries such as automotive, construction, and manufacturing. These extractors are designed to be easily moved and positioned close to the welding source, ensuring maximum efficiency in capturing and filtering out harmful particles before they can be inhaled by workers. The market is characterized by continuous innovation, with manufacturers focusing on enhancing the efficiency, portability, and ease of use of these devices to meet the evolving needs of end-users.

Automatic Cleaning, Manual Cleaning in the Global Portable Welding Fume Extractor Market:

In the Global Portable Welding Fume Extractor Market, there are two primary types of cleaning mechanisms: automatic cleaning and manual cleaning. Automatic cleaning systems are designed to reduce the need for human intervention by using mechanisms such as reverse air pulses or mechanical shakers to clean the filters. These systems are highly efficient and can significantly extend the lifespan of the filters by ensuring they remain unclogged and functional. Automatic cleaning is particularly beneficial in high-volume welding operations where the extractors are in constant use, as it minimizes downtime and maintenance efforts. On the other hand, manual cleaning systems require the operator to periodically remove and clean the filters by hand. While this method can be more labor-intensive and time-consuming, it allows for a more thorough inspection of the filters and the overall system. Manual cleaning is often preferred in smaller operations or in situations where the welding fume extractors are not used continuously. Both cleaning methods have their advantages and disadvantages, and the choice between them often depends on factors such as the scale of the welding operations, budget constraints, and specific user preferences. In terms of market trends, there is a growing preference for automatic cleaning systems due to their convenience and efficiency. However, manual cleaning systems continue to be popular in certain segments due to their lower initial cost and the ability to perform detailed maintenance checks. The market for portable welding fume extractors is also influenced by advancements in filter technology, with newer filters offering improved performance and longer service life. Additionally, the increasing focus on sustainability and environmental regulations is driving the development of more eco-friendly cleaning systems that reduce waste and energy consumption. Overall, the choice between automatic and manual cleaning systems in the Global Portable Welding Fume Extractor Market is shaped by a combination of operational needs, cost considerations, and technological advancements.

Arc Welding, Resistance Welding, Laser Beam Welding, Oxy Fuel Welding, Others in the Global Portable Welding Fume Extractor Market:

The Global Portable Welding Fume Extractor Market finds its applications across various welding techniques, including Arc Welding, Resistance Welding, Laser Beam Welding, Oxy Fuel Welding, and others. In Arc Welding, which is one of the most common welding methods, portable fume extractors are crucial for capturing the fumes generated by the electric arc used to melt and join metals. These fumes can contain harmful substances like manganese, chromium, and nickel, which pose significant health risks to welders. Portable fume extractors help in maintaining air quality and ensuring compliance with occupational safety standards. In Resistance Welding, where heat is generated by passing an electric current through the metal pieces to be joined, fume extractors are used to capture the smoke and particulate matter produced during the process. This type of welding is often used in the automotive and electronics industries, where maintaining a clean working environment is essential for both worker safety and product quality. Laser Beam Welding, which uses a focused laser beam to melt and join metals, produces very fine particulate matter and fumes that can be hazardous if inhaled. Portable fume extractors equipped with high-efficiency filters are essential in capturing these fine particles and ensuring a safe working environment. Oxy Fuel Welding, which involves the use of a fuel gas and oxygen to produce a flame for welding, cutting, or brazing metals, generates fumes that can contain toxic gases and metal oxides. Portable fume extractors are used to capture these fumes at the source, preventing them from dispersing into the workplace. Other welding techniques, such as TIG (Tungsten Inert Gas) and MIG (Metal Inert Gas) welding, also benefit from the use of portable fume extractors to maintain air quality and protect workers from exposure to harmful fumes. The versatility and portability of these extractors make them suitable for use in various industrial settings, including construction sites, manufacturing plants, and repair workshops. Overall, the Global Portable Welding Fume Extractor Market plays a vital role in ensuring the safety and health of workers across different welding applications by effectively capturing and filtering out hazardous fumes and particulate matter.

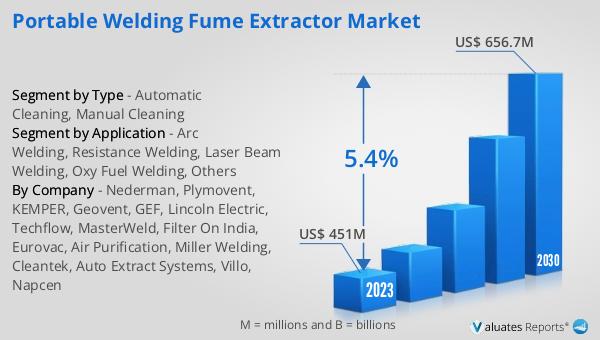

Global Portable Welding Fume Extractor Market Outlook:

The global Portable Welding Fume Extractor market was valued at US$ 451 million in 2023 and is anticipated to reach US$ 656.7 million by 2030, witnessing a CAGR of 5.4% during the forecast period 2024-2030. This growth can be attributed to several factors, including the increasing awareness about the health risks associated with welding fumes, stringent occupational safety regulations, and the growing adoption of welding activities across various industries. The market is characterized by continuous innovation, with manufacturers focusing on enhancing the efficiency, portability, and ease of use of these devices to meet the evolving needs of end-users. The demand for portable welding fume extractors is also driven by the need to maintain a safe and healthy working environment, as welding fumes can contain hazardous substances like metal oxides, silicates, and fluorides. The market encompasses a wide range of products, including various sizes and types of fume extractors, each tailored to different welding applications and environments. The increasing focus on sustainability and environmental regulations is also driving the development of more eco-friendly cleaning systems that reduce waste and energy consumption. Overall, the Global Portable Welding Fume Extractor Market is expected to witness significant growth in the coming years, driven by the increasing demand for effective fume extraction solutions and the continuous advancements in technology.

| Report Metric | Details |

| Report Name | Portable Welding Fume Extractor Market |

| Accounted market size in 2023 | US$ 451 million |

| Forecasted market size in 2030 | US$ 656.7 million |

| CAGR | 5.4% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Nederman, Plymovent, KEMPER, Geovent, GEF, Lincoln Electric, Techflow, MasterWeld, Filter On India, Eurovac, Air Purification, Miller Welding, Cleantek, Auto Extract Systems, Villo, Napcen |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |