What is Global Medical Plastic Precision Molding Services Market?

The Global Medical Plastic Precision Molding Services Market is a specialized sector within the broader medical device industry. It focuses on the production of high-precision plastic components used in various medical applications. These services involve the use of advanced molding techniques to create intricate and accurate plastic parts that meet stringent medical standards. The market caters to the needs of medical device manufacturers by providing them with custom-molded plastic parts that are essential for the functionality and reliability of medical devices. These components can range from small, intricate parts used in surgical instruments to larger, more complex parts used in diagnostic equipment. The precision molding process ensures that each part is produced with high accuracy, consistency, and quality, which is crucial for the safety and effectiveness of medical devices. The market is driven by the increasing demand for advanced medical devices, the need for cost-effective manufacturing solutions, and the growing emphasis on patient safety and regulatory compliance.

Prototyping, Short-run Production, Long-term Production in the Global Medical Plastic Precision Molding Services Market:

Prototyping, short-run production, and long-term production are three critical phases in the Global Medical Plastic Precision Molding Services Market. Prototyping is the initial stage where a preliminary model of the plastic component is created. This phase is crucial for testing and validating the design before mass production. It allows manufacturers to identify and rectify any design flaws, ensuring that the final product meets all specifications and regulatory requirements. Prototyping involves the use of advanced technologies such as 3D printing and computer-aided design (CAD) to create accurate and functional prototypes quickly and cost-effectively. Short-run production follows prototyping and involves the manufacturing of a limited quantity of plastic components. This phase is often used for pilot testing, clinical trials, or market testing. Short-run production allows manufacturers to produce a small batch of components to gather feedback, make necessary adjustments, and ensure that the product performs as expected in real-world conditions. It also helps in assessing the feasibility of scaling up production. Long-term production is the final phase, where the plastic components are manufactured in large quantities for commercial distribution. This phase requires robust production processes, quality control measures, and efficient supply chain management to meet the high demand and ensure consistent quality. Long-term production often involves the use of automated molding machines, advanced materials, and stringent quality assurance protocols to maintain the highest standards of precision and reliability. Each of these phases plays a vital role in the development and manufacturing of medical plastic components, ensuring that they meet the rigorous demands of the medical industry.

Medical, Biological, Pharmaceutical in the Global Medical Plastic Precision Molding Services Market:

The usage of Global Medical Plastic Precision Molding Services Market spans across various areas, including medical, biological, and pharmaceutical fields. In the medical field, precision-molded plastic components are used in a wide range of devices such as syringes, catheters, surgical instruments, and diagnostic equipment. These components are designed to meet strict regulatory standards and ensure patient safety. The high precision and quality of these molded parts are crucial for the proper functioning of medical devices, which directly impacts patient outcomes. In the biological field, precision molding services are used to create components for laboratory equipment, such as pipettes, petri dishes, and microfluidic devices. These components are essential for conducting accurate and reliable biological research and experiments. The use of high-quality plastic materials ensures that the components are durable, chemically resistant, and capable of withstanding various laboratory conditions. In the pharmaceutical field, precision-molded plastic components are used in drug delivery systems, such as inhalers, insulin pens, and blister packs. These components play a critical role in ensuring the accurate and safe delivery of medications to patients. The precision molding process ensures that each component is produced with high accuracy and consistency, which is essential for maintaining the efficacy and safety of pharmaceutical products. Overall, the Global Medical Plastic Precision Molding Services Market plays a vital role in supporting the medical, biological, and pharmaceutical industries by providing high-quality, precision-molded plastic components that meet the stringent requirements of these fields.

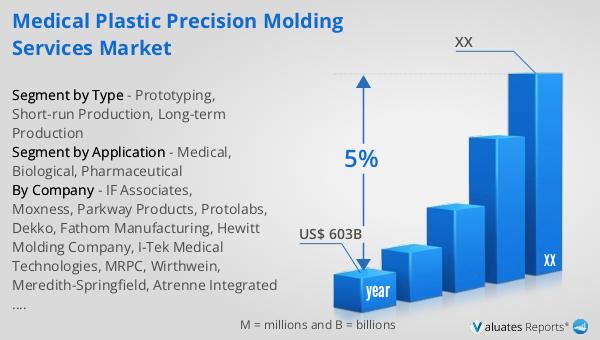

Global Medical Plastic Precision Molding Services Market Outlook:

Based on our research, the global market for medical devices is projected to reach approximately US$ 603 billion by the year 2023, with an anticipated growth rate of 5% annually over the next six years. This growth is driven by several factors, including advancements in medical technology, increasing demand for healthcare services, and the rising prevalence of chronic diseases. The market's expansion is also supported by the growing emphasis on patient safety and regulatory compliance, which necessitates the use of high-quality, precision-molded plastic components in medical devices. As the demand for advanced medical devices continues to rise, the Global Medical Plastic Precision Molding Services Market is expected to play a crucial role in meeting this demand by providing reliable and cost-effective manufacturing solutions. The precision and quality of molded plastic components are essential for the proper functioning and safety of medical devices, making this market an integral part of the healthcare industry. With the ongoing advancements in molding technologies and materials, the market is well-positioned to support the evolving needs of the medical, biological, and pharmaceutical fields, ensuring the continued development and availability of innovative medical devices.

| Report Metric | Details |

| Report Name | Medical Plastic Precision Molding Services Market |

| Accounted market size in year | US$ 603 billion |

| CAGR | 5% |

| Base Year | year |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | IF Associates, Moxness, Parkway Products, Protolabs, Dekko, Fathom Manufacturing, Hewitt Molding Company, I-Tek Medical Technologies, MRPC, Wirthwein, Meredith-Springfield, Atrenne Integrated Solutions, Xeridiem Medical Devices, Premier Technical Plastics, Medron, Flambeau, RPM Plastic Molding, Source International, Xometry, Vaupell, dlhBOWLES |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |