What is Global Medical Heat Exchanger Market?

The Global Medical Heat Exchanger Market is a specialized segment within the broader medical devices industry, focusing on devices that transfer heat between two or more fluids. These heat exchangers are crucial in various medical applications, such as maintaining the temperature of medical equipment, patient care devices, and laboratory instruments. They ensure that medical devices operate within optimal temperature ranges, which is vital for their accuracy and longevity. The market encompasses a variety of heat exchanger types, including plate, rotary, and shell and tube heat exchangers, each designed to meet specific needs within the medical field. The demand for these devices is driven by the increasing complexity of medical equipment and the growing emphasis on patient safety and comfort. As healthcare facilities continue to adopt advanced technologies, the need for efficient and reliable heat exchangers is expected to rise, making this market a critical component of the global healthcare infrastructure.

Plate Heat Exchanger, Rotary Heat Exchanger in the Global Medical Heat Exchanger Market:

Plate heat exchangers and rotary heat exchangers are two prominent types within the Global Medical Heat Exchanger Market. Plate heat exchangers consist of multiple thin, corrugated plates stacked together, creating a series of channels for fluids to flow through. These plates are typically made of stainless steel or titanium, materials known for their durability and resistance to corrosion. The design allows for a large surface area in a compact space, making them highly efficient in transferring heat. They are commonly used in applications where precise temperature control is essential, such as in dialysis machines, blood warmers, and laboratory equipment. The efficiency of plate heat exchangers lies in their ability to facilitate a high rate of heat transfer while maintaining a small footprint, which is particularly beneficial in medical settings where space is often limited. On the other hand, rotary heat exchangers, also known as rotary wheel or regenerative heat exchangers, operate on a different principle. They consist of a rotating wheel made of a material with high thermal conductivity, such as aluminum. As the wheel rotates, it alternately passes through hot and cold air streams, absorbing heat from the hot stream and releasing it into the cold stream. This continuous process allows for efficient heat recovery and transfer. Rotary heat exchangers are particularly useful in ventilation systems within hospitals and clinics, where maintaining a controlled indoor climate is crucial for patient comfort and infection control. They are also employed in sterilization equipment, where precise temperature regulation is necessary to ensure the effectiveness of the sterilization process. Both plate and rotary heat exchangers play vital roles in the medical field, each offering unique advantages. Plate heat exchangers are favored for their compact size and high efficiency, making them ideal for applications where space and precision are critical. Rotary heat exchangers, with their ability to recover and reuse heat, contribute to energy efficiency and cost savings in large-scale medical facilities. The choice between the two types depends on the specific requirements of the application, including factors such as the desired temperature range, space constraints, and energy efficiency goals. As the medical industry continues to evolve, the demand for advanced heat exchanger technologies is expected to grow, driving innovation and development in this specialized market.

Medical, Commercial in the Global Medical Heat Exchanger Market:

The usage of Global Medical Heat Exchanger Market extends across various areas, including medical and commercial applications. In the medical field, heat exchangers are indispensable in ensuring the proper functioning of critical equipment. For instance, in dialysis machines, plate heat exchangers are used to maintain the temperature of the dialysis fluid, ensuring patient safety and comfort. Similarly, in blood warmers, these devices help regulate the temperature of blood before transfusion, preventing complications associated with cold blood transfusions. Laboratory equipment, such as PCR machines and incubators, also rely on heat exchangers to maintain precise temperature conditions necessary for accurate results. In surgical settings, heat exchangers are used in devices like heart-lung machines and anesthesia machines to regulate the temperature of fluids and gases, ensuring optimal performance and patient safety. In commercial applications, heat exchangers are used in hospital HVAC systems to maintain a controlled indoor climate. Rotary heat exchangers, in particular, are employed in ventilation systems to recover and reuse heat, contributing to energy efficiency and cost savings. These systems are crucial in maintaining a comfortable and safe environment for patients, staff, and visitors. Additionally, heat exchangers are used in sterilization equipment, where precise temperature control is necessary to ensure the effectiveness of the sterilization process. This is particularly important in preventing the spread of infections and ensuring the safety of medical instruments and devices. Moreover, heat exchangers are used in medical imaging equipment, such as MRI and CT scanners, to dissipate the heat generated during operation. This helps maintain the accuracy and reliability of the imaging results, which are critical for accurate diagnosis and treatment planning. In pharmaceutical manufacturing, heat exchangers are used in various processes, including the production of vaccines and other temperature-sensitive medications. They help maintain the required temperature conditions, ensuring the quality and efficacy of the final product. Overall, the usage of heat exchangers in both medical and commercial applications highlights their importance in the healthcare industry. They play a crucial role in ensuring the proper functioning of medical equipment, maintaining a safe and comfortable environment in healthcare facilities, and supporting the production of high-quality pharmaceuticals. As the demand for advanced medical technologies continues to grow, the need for efficient and reliable heat exchangers is expected to increase, driving further innovation and development in this market.

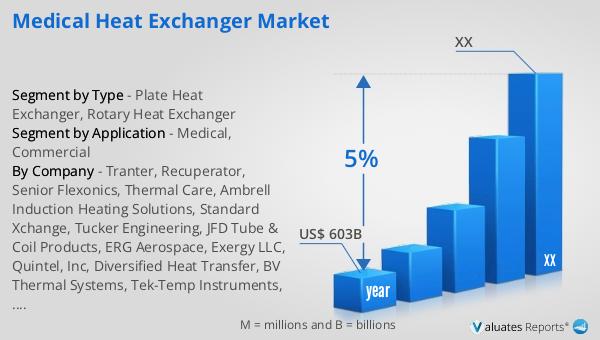

Global Medical Heat Exchanger Market Outlook:

Based on our research, the global market for medical devices is projected to reach approximately $603 billion by 2023, with an anticipated compound annual growth rate (CAGR) of 5% over the next six years. This growth is indicative of the increasing demand for advanced medical technologies and devices across the globe. The medical device industry encompasses a wide range of products, including diagnostic equipment, surgical instruments, and patient monitoring systems, all of which play a crucial role in modern healthcare. The steady growth rate reflects the ongoing advancements in medical technology, the rising prevalence of chronic diseases, and the increasing emphasis on improving patient outcomes. As healthcare systems worldwide continue to evolve and adopt new technologies, the demand for innovative medical devices is expected to rise, driving the overall growth of the market. This positive outlook underscores the importance of continued investment in research and development to meet the evolving needs of the healthcare industry and improve patient care.

| Report Metric | Details |

| Report Name | Medical Heat Exchanger Market |

| Accounted market size in year | US$ 603 billion |

| CAGR | 5% |

| Base Year | year |

| Segment by Type |

|

| Segment by Application |

|

| Consumption by Region |

|

| By Company | Tranter, Recuperator, Senior Flexonics, Thermal Care, Ambrell Induction Heating Solutions, Standard Xchange, Tucker Engineering, JFD Tube & Coil Products, ERG Aerospace, Exergy LLC, Quintel, Inc, Diversified Heat Transfer, BV Thermal Systems, Tek-Temp Instruments, Rubicon Industries |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |