What is Global Medical Grade PVC Material Market?

The Global Medical Grade PVC Material Market refers to the worldwide industry focused on the production and distribution of polyvinyl chloride (PVC) materials specifically designed for medical applications. These materials are used in a variety of medical devices and products due to their excellent properties such as flexibility, durability, and resistance to chemicals and sterilization processes. Medical grade PVC is essential in ensuring the safety and effectiveness of medical instruments and consumables, which are critical in patient care. The market encompasses a wide range of products, including tubing, containers, and other medical devices that require high standards of biocompatibility and performance. The demand for medical grade PVC is driven by the growing healthcare industry, advancements in medical technology, and the increasing need for disposable medical products. As healthcare systems around the world continue to expand and modernize, the importance of reliable and high-quality medical grade PVC materials becomes even more significant.

Soft PVC, Rigid PVC in the Global Medical Grade PVC Material Market:

Soft PVC and Rigid PVC are two primary types of polyvinyl chloride materials used in the Global Medical Grade PVC Material Market, each with distinct properties and applications. Soft PVC, also known as flexible PVC, is characterized by its pliability and elasticity, making it ideal for applications that require flexibility and ease of handling. This type of PVC is commonly used in medical tubing, blood bags, and other fluid delivery systems where flexibility is crucial for patient comfort and ease of use. The softness of the material allows it to be easily manipulated and shaped, which is essential in creating custom-fit medical devices that can adapt to various medical procedures and patient needs. Additionally, soft PVC is resistant to kinking and cracking, ensuring the reliability and safety of medical devices during use. On the other hand, Rigid PVC, also known as hard PVC, is known for its strength and durability. This type of PVC is used in applications where structural integrity and resistance to impact are essential. Rigid PVC is commonly found in medical device housings, containers, and other components that require a sturdy and stable material. The rigidity of the material provides excellent protection for sensitive medical instruments and ensures that they can withstand the rigors of sterilization processes and repeated use. Rigid PVC is also resistant to chemicals and moisture, making it suitable for use in environments where hygiene and cleanliness are paramount. Both Soft PVC and Rigid PVC play crucial roles in the medical field, each offering unique advantages that cater to specific needs and applications. The choice between soft and rigid PVC depends on the requirements of the medical device or product being developed. For instance, in applications where flexibility and patient comfort are prioritized, soft PVC is the preferred choice. In contrast, for applications that demand durability and structural integrity, rigid PVC is more suitable. The versatility of PVC materials allows manufacturers to create a wide range of medical products that meet the diverse needs of the healthcare industry. The production of medical grade PVC involves stringent quality control measures to ensure that the materials meet the high standards required for medical applications. This includes testing for biocompatibility, chemical resistance, and mechanical properties to ensure that the PVC materials are safe and effective for use in medical devices. Manufacturers also need to comply with regulatory requirements and industry standards to ensure that their products are suitable for use in healthcare settings. In conclusion, the Global Medical Grade PVC Material Market is a vital component of the healthcare industry, providing essential materials for the production of medical devices and consumables. Soft PVC and Rigid PVC each offer unique properties that make them suitable for different applications, ensuring that medical products are safe, reliable, and effective. As the demand for high-quality medical devices continues to grow, the importance of medical grade PVC materials will only increase, driving innovation and advancements in the field.

Medical Instruments, Consumables in the Global Medical Grade PVC Material Market:

The usage of Global Medical Grade PVC Material Market in medical instruments and consumables is extensive and varied, reflecting the versatility and reliability of PVC materials in healthcare applications. Medical instruments, such as catheters, IV bags, and surgical gloves, rely heavily on medical grade PVC for their construction. The flexibility and durability of soft PVC make it an ideal material for catheters and IV bags, which need to be both pliable and strong to ensure patient comfort and safety. These instruments are often used in critical care settings, where the reliability of the materials can directly impact patient outcomes. The ability of soft PVC to withstand sterilization processes without degrading ensures that these instruments remain safe and effective throughout their use. In addition to medical instruments, medical grade PVC is also widely used in consumables, such as tubing, blood bags, and dialysis equipment. The biocompatibility of PVC materials ensures that they do not cause adverse reactions when in contact with bodily fluids, making them suitable for use in a variety of medical procedures. For example, blood bags made from soft PVC are essential in blood transfusion processes, where the integrity of the bag and the safety of the stored blood are paramount. The flexibility of the material allows for easy handling and storage, while its durability ensures that the blood remains uncontaminated and safe for transfusion. Dialysis equipment is another critical application of medical grade PVC, where the material's resistance to chemicals and moisture is crucial. The tubing and containers used in dialysis machines must be able to withstand repeated exposure to cleaning agents and sterilization processes without compromising their structural integrity. Rigid PVC is often used in these applications due to its strength and durability, ensuring that the equipment remains reliable and effective over time. The use of medical grade PVC in dialysis equipment helps to ensure that patients receive safe and effective treatment, improving their quality of life. Furthermore, medical grade PVC is also used in the production of surgical drapes, gowns, and other protective equipment. The material's resistance to moisture and chemicals makes it suitable for use in sterile environments, where maintaining hygiene and preventing contamination are critical. The durability of PVC ensures that these protective items can withstand the rigors of surgical procedures, providing a reliable barrier against infections and contaminants. The use of medical grade PVC in protective equipment helps to ensure the safety of both patients and healthcare professionals, reducing the risk of infections and improving overall patient care. In conclusion, the usage of Global Medical Grade PVC Material Market in medical instruments and consumables is extensive and varied, reflecting the material's versatility and reliability in healthcare applications. From catheters and IV bags to blood bags and dialysis equipment, medical grade PVC plays a crucial role in ensuring the safety and effectiveness of medical devices and consumables. The material's biocompatibility, durability, and resistance to chemicals and moisture make it an ideal choice for a wide range of medical applications, helping to improve patient outcomes and enhance the quality of care provided by healthcare professionals. As the demand for high-quality medical devices and consumables continues to grow, the importance of medical grade PVC materials will only increase, driving innovation and advancements in the field.

Global Medical Grade PVC Material Market Outlook:

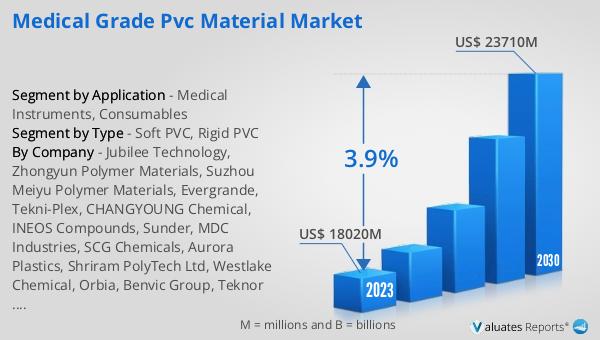

The global Medical Grade PVC Material market was valued at US$ 18,020 million in 2023 and is anticipated to reach US$ 23,710 million by 2030, witnessing a CAGR of 3.9% during the forecast period 2024-2030. This market outlook indicates a steady growth trajectory for medical grade PVC materials, driven by the increasing demand for high-quality medical devices and consumables. The projected growth reflects the expanding healthcare industry and the continuous advancements in medical technology that require reliable and effective materials. The market's valuation highlights the significant role that medical grade PVC plays in the production of essential medical products, ensuring their safety and performance. As healthcare systems around the world continue to evolve and modernize, the demand for medical grade PVC materials is expected to rise, supporting the development of innovative medical solutions and improving patient care. The anticipated growth in the market underscores the importance of investing in high-quality PVC materials to meet the stringent requirements of the healthcare industry and to support the ongoing advancements in medical technology.

| Report Metric | Details |

| Report Name | Medical Grade PVC Material Market |

| Accounted market size in 2023 | US$ 18020 million |

| Forecasted market size in 2030 | US$ 23710 million |

| CAGR | 3.9% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Jubilee Technology, Zhongyun Polymer Materials, Suzhou Meiyu Polymer Materials, Evergrande, Tekni-Plex, CHANGYOUNG Chemical, INEOS Compounds, Sunder, MDC Industries, SCG Chemicals, Aurora Plastics, Shriram PolyTech Ltd, Westlake Chemical, Orbia, Benvic Group, Teknor Apex, Flex Technologies, Empol (IFFCO), GEON Performance Solutions, Konnark Polymer, Mazda Plastic, Thevinyl, RIKEN |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |