What is Global Medical Component Laser Marking Services Market?

The Global Medical Component Laser Marking Services Market is a specialized sector that focuses on the precise and permanent marking of medical components using laser technology. This market is crucial for ensuring the traceability, identification, and compliance of medical devices and components. Laser marking is preferred over traditional methods due to its high precision, durability, and ability to mark a wide range of materials without causing damage. The process involves using a focused laser beam to create marks such as serial numbers, barcodes, logos, and other essential information on medical components. These marks are vital for maintaining the integrity and safety of medical devices, as they help in tracking the history and usage of each component. The market serves various stakeholders, including medical device manufacturers, healthcare providers, and regulatory bodies, ensuring that all medical components meet stringent quality and safety standards. The demand for laser marking services is driven by the increasing complexity of medical devices, the need for enhanced traceability, and stringent regulatory requirements. As the medical industry continues to evolve, the Global Medical Component Laser Marking Services Market plays a pivotal role in supporting the development and maintenance of high-quality medical devices.

Infrared Laser, Green Laser in the Global Medical Component Laser Marking Services Market:

Infrared lasers and green lasers are two prominent types of lasers used in the Global Medical Component Laser Marking Services Market. Infrared lasers, typically operating at wavelengths around 1064 nm, are widely used for marking metals and certain plastics. They are known for their deep penetration capabilities, making them ideal for creating durable and legible marks on hard surfaces. Infrared lasers can efficiently mark stainless steel, titanium, and other metals commonly used in medical devices. They are also effective in marking certain types of plastics, although their performance may vary depending on the material's composition. On the other hand, green lasers operate at a wavelength of 532 nm and are particularly effective for marking non-metallic materials, including ceramics, glass, and some plastics. The shorter wavelength of green lasers allows for higher absorption by these materials, resulting in precise and high-contrast marks. Green lasers are often used for marking medical components that require high visibility and clarity, such as surgical instruments and diagnostic equipment. Both infrared and green lasers offer unique advantages in the medical component laser marking market, catering to different material requirements and marking needs. The choice between the two depends on factors such as the type of material, desired mark quality, and specific application requirements. As the medical industry continues to advance, the demand for both infrared and green laser marking services is expected to grow, driven by the need for high-quality, durable, and compliant markings on a wide range of medical components.

Metal, Non-metal in the Global Medical Component Laser Marking Services Market:

The usage of Global Medical Component Laser Marking Services Market extends to both metal and non-metal materials, each with its unique requirements and applications. For metal materials, laser marking is extensively used to create permanent and precise marks on components such as surgical instruments, implants, and medical devices. Metals like stainless steel, titanium, and aluminum are commonly used in the medical industry due to their durability and biocompatibility. Laser marking on these metals ensures that essential information such as serial numbers, batch codes, and manufacturer details are clearly visible and resistant to wear and corrosion. This is crucial for maintaining traceability and compliance with regulatory standards. The high precision of laser marking also allows for the creation of intricate designs and logos, enhancing the branding and identification of medical devices. In contrast, non-metal materials such as plastics, ceramics, and glass also benefit from laser marking services. These materials are often used in disposable medical devices, diagnostic equipment, and packaging. Laser marking on non-metals provides high-contrast and legible marks without damaging the material's integrity. For instance, plastic components used in syringes, tubing, and connectors can be marked with important information such as expiration dates, usage instructions, and safety warnings. Similarly, ceramic and glass components used in laboratory equipment and diagnostic devices can be marked with precise and durable labels, ensuring accurate identification and usage. The versatility of laser marking technology allows it to cater to a wide range of materials, making it an indispensable tool in the medical industry. Whether it is for metal or non-metal components, laser marking ensures that all medical devices and components meet the highest standards of quality, safety, and compliance.

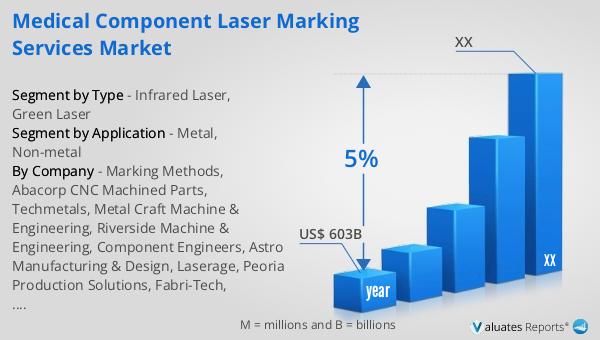

Global Medical Component Laser Marking Services Market Outlook:

According to our research, the global market for medical devices is projected to reach approximately US$ 603 billion in 2023, with an anticipated growth rate of 5% CAGR over the next six years. This significant market size underscores the critical role of medical devices in the healthcare industry, driving the demand for advanced technologies and services, including laser marking. The growth in the medical device market is fueled by factors such as technological advancements, increasing healthcare expenditure, and the rising prevalence of chronic diseases. As the market expands, the need for precise and durable marking of medical components becomes even more crucial. Laser marking services play a vital role in ensuring the traceability, identification, and compliance of medical devices, supporting the overall growth and development of the industry. The projected growth rate highlights the ongoing advancements and innovations in the medical device sector, emphasizing the importance of high-quality and reliable marking solutions. As the market continues to evolve, the demand for laser marking services is expected to rise, driven by the need for enhanced traceability, regulatory compliance, and improved patient safety. The Global Medical Component Laser Marking Services Market is poised to play a pivotal role in supporting the growth and development of the medical device industry, ensuring that all components meet the highest standards of quality and safety.

| Report Metric | Details |

| Report Name | Medical Component Laser Marking Services Market |

| Accounted market size in year | US$ 603 billion |

| CAGR | 5% |

| Base Year | year |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Marking Methods, Abacorp CNC Machined Parts, Techmetals, Metal Craft Machine & Engineering, Riverside Machine & Engineering, Component Engineers, Astro Manufacturing & Design, Laserage, Peoria Production Solutions, Fabri-Tech, Accumet Engineering, Arrow Cryogenics, Mac Machine Company, Vita Needle, CED Services, Serviscreen Corporation, MicroGroup, Omni Components, Acceleron, Brinkman Precision, Grace Manufacturing |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |