What is Global Machine Vision Linear Array Lights Market?

The Global Machine Vision Linear Array Lights Market is a specialized segment within the broader machine vision industry. Machine vision systems are used to automate visual inspection and analysis tasks, and linear array lights are a crucial component of these systems. These lights are designed to provide consistent and uniform illumination, which is essential for capturing high-quality images. The market for these lights is driven by the increasing demand for automation in various industries such as manufacturing, automotive, electronics, and pharmaceuticals. These industries rely on machine vision systems for tasks like quality control, defect detection, and assembly verification. The global market for machine vision linear array lights is characterized by technological advancements, increasing adoption of automation, and the need for high precision in industrial processes. As industries continue to seek ways to improve efficiency and reduce human error, the demand for machine vision linear array lights is expected to grow.

Strobe Type, Continuous Type in the Global Machine Vision Linear Array Lights Market:

In the Global Machine Vision Linear Array Lights Market, there are two primary types of lighting: Strobe Type and Continuous Type. Strobe Type lighting involves the use of short, intense bursts of light to illuminate an object. This type of lighting is particularly useful in high-speed applications where objects are moving quickly, and a clear, sharp image is required. The strobe light freezes the motion of the object, allowing for precise inspection and measurement. Strobe lights are commonly used in industries such as automotive manufacturing, where components move rapidly along assembly lines, and any defects need to be detected instantly. On the other hand, Continuous Type lighting provides a steady, constant light source. This type of lighting is ideal for applications where consistent illumination is needed over a longer period. Continuous lights are often used in scenarios where the object being inspected is stationary or moving slowly. They are also preferred in applications where the lighting conditions need to be stable and uniform to ensure accurate image capture. Both types of lighting have their advantages and are chosen based on the specific requirements of the application. For instance, in the electronics industry, where tiny components need to be inspected with high precision, continuous lighting might be preferred to ensure every detail is visible. In contrast, in the packaging industry, where products move quickly along conveyor belts, strobe lighting might be more effective. The choice between strobe and continuous lighting also depends on factors such as the speed of the production line, the size and nature of the objects being inspected, and the level of detail required in the inspection process. As technology advances, both types of lighting are becoming more efficient and versatile, offering better performance and energy efficiency. This ongoing development is expected to further drive the adoption of machine vision linear array lights in various industries, enhancing the capabilities of automated inspection systems and contributing to improved quality control and operational efficiency.

Bright Field Lighting, Dark Field Lighting in the Global Machine Vision Linear Array Lights Market:

The usage of Global Machine Vision Linear Array Lights Market in Bright Field Lighting and Dark Field Lighting is essential for various industrial applications. Bright Field Lighting involves illuminating the object directly from the front, creating a bright background and highlighting the object's surface features. This type of lighting is ideal for inspecting objects with flat, reflective surfaces, as it enhances the visibility of surface defects such as scratches, dents, and other imperfections. Bright Field Lighting is commonly used in industries like semiconductor manufacturing, where the quality of the surface is critical. It is also used in the inspection of printed circuit boards (PCBs), where the clarity of the surface features is essential for detecting defects. On the other hand, Dark Field Lighting involves illuminating the object from the sides at a low angle, creating a dark background and highlighting the edges and contours of the object. This type of lighting is particularly useful for inspecting objects with textured or irregular surfaces, as it enhances the visibility of edges, cracks, and other surface irregularities. Dark Field Lighting is commonly used in industries such as automotive manufacturing, where the detection of small cracks and defects in metal components is crucial. It is also used in the inspection of glass and plastic products, where the detection of surface defects is essential for ensuring product quality. Both Bright Field and Dark Field Lighting have their unique advantages and are chosen based on the specific requirements of the inspection process. For instance, in the pharmaceutical industry, where the inspection of tablet surfaces is critical, Bright Field Lighting might be preferred to ensure the visibility of surface defects. In contrast, in the aerospace industry, where the detection of small cracks in metal components is crucial, Dark Field Lighting might be more effective. The choice between Bright Field and Dark Field Lighting also depends on factors such as the nature of the object being inspected, the type of defects that need to be detected, and the level of detail required in the inspection process. As technology advances, both types of lighting are becoming more efficient and versatile, offering better performance and energy efficiency. This ongoing development is expected to further drive the adoption of machine vision linear array lights in various industries, enhancing the capabilities of automated inspection systems and contributing to improved quality control and operational efficiency.

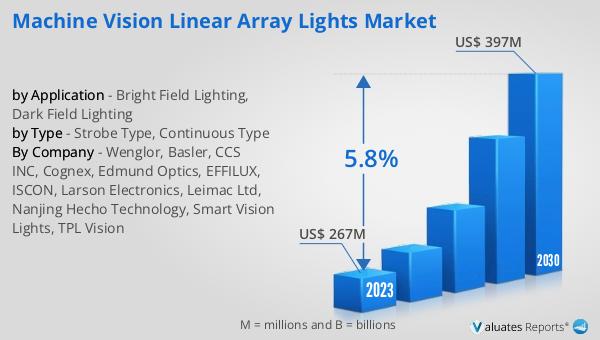

Global Machine Vision Linear Array Lights Market Outlook:

The global Machine Vision Linear Array Lights market was valued at US$ 267 million in 2023 and is anticipated to reach US$ 397 million by 2030, witnessing a CAGR of 5.8% during the forecast period 2024-2030. This growth is driven by the increasing demand for automation and precision in various industries such as manufacturing, automotive, electronics, and pharmaceuticals. Machine vision systems, which rely on linear array lights for consistent and uniform illumination, are essential for tasks like quality control, defect detection, and assembly verification. The market is characterized by technological advancements, increasing adoption of automation, and the need for high precision in industrial processes. As industries continue to seek ways to improve efficiency and reduce human error, the demand for machine vision linear array lights is expected to grow. The ongoing development of more efficient and versatile lighting solutions is also expected to contribute to the market's growth, enhancing the capabilities of automated inspection systems and improving quality control and operational efficiency.

| Report Metric | Details |

| Report Name | Machine Vision Linear Array Lights Market |

| Accounted market size in 2023 | US$ 267 million |

| Forecasted market size in 2030 | US$ 397 million |

| CAGR | 5.8% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Wenglor, Basler, CCS INC, Cognex, Edmund Optics, EFFILUX, ISCON, Larson Electronics, Leimac Ltd, Nanjing Hecho Technology, Smart Vision Lights, TPL Vision |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |