What is Global Linear Drive Linear Motor Market?

The Global Linear Drive Linear Motor Market refers to the worldwide industry focused on the production, distribution, and utilization of linear drive linear motors. These motors are specialized devices that convert electrical energy into linear motion, as opposed to the rotational motion produced by traditional motors. They are used in various applications where precise and efficient linear movement is required. The market encompasses a wide range of industries, including automotive, healthcare, aerospace, national defense, and industrial manufacturing. The demand for linear drive linear motors is driven by their ability to provide high-speed, high-precision motion control, which is essential for modern automation and advanced manufacturing processes. As industries continue to adopt automation and robotics, the need for reliable and efficient linear motors is expected to grow, making this market a critical component of the global industrial landscape.

Ironcore, Ironless in the Global Linear Drive Linear Motor Market:

Ironcore and ironless linear motors are two primary types of linear drive linear motors used in various applications. Ironcore linear motors, as the name suggests, have an iron core in their construction. This iron core provides a strong magnetic field, resulting in high force output and efficiency. These motors are known for their robustness and ability to handle heavy loads, making them ideal for applications requiring high thrust and precision, such as in industrial machinery and automation systems. However, the presence of the iron core can lead to cogging, which is a slight jerking motion that can affect the smoothness of the motor's operation. To mitigate this, advanced control techniques and design optimizations are often employed. On the other hand, ironless linear motors do not have an iron core. Instead, they use a coil assembly that is suspended in a magnetic field. This design eliminates the cogging effect, resulting in extremely smooth and precise motion. Ironless linear motors are particularly suited for applications where high precision and smooth operation are critical, such as in semiconductor manufacturing, medical devices, and precision measurement equipment. The absence of an iron core also makes these motors lighter and more responsive, which can be advantageous in applications requiring rapid acceleration and deceleration. Both ironcore and ironless linear motors have their unique advantages and are chosen based on the specific requirements of the application. For instance, in the automotive industry, ironcore linear motors might be preferred for tasks such as welding and assembly, where high force and durability are essential. In contrast, ironless linear motors might be used in the production of precision components, where smooth and accurate motion is paramount. Similarly, in the healthcare sector, ironless linear motors are often used in medical imaging equipment and robotic surgery systems, where precision and smooth operation are crucial. In the aerospace industry, both types of linear motors find applications in various systems, including flight simulators, satellite positioning systems, and precision manufacturing of aerospace components. The choice between ironcore and ironless motors depends on the specific performance requirements and operational conditions of the application. National defense applications also benefit from the unique characteristics of both motor types. Ironcore linear motors might be used in heavy-duty applications such as missile guidance systems and military vehicle automation, while ironless motors could be employed in precision targeting systems and advanced surveillance equipment. In industrial manufacturing, the versatility of linear drive linear motors allows them to be used in a wide range of applications, from material handling and packaging to CNC machinery and robotic arms. The choice between ironcore and ironless motors is often dictated by the specific needs of the manufacturing process, such as the required force, precision, and operational smoothness. Overall, the global linear drive linear motor market is characterized by a diverse range of applications and a continuous drive for innovation and improvement in motor technology to meet the evolving demands of various industries.

Automobile, Healthcare, Aerospace, National Defense, Industrial Manufacture, Others in the Global Linear Drive Linear Motor Market:

The usage of Global Linear Drive Linear Motor Market spans across several key industries, each benefiting from the unique capabilities of these motors. In the automobile industry, linear drive linear motors are used in various manufacturing processes, including welding, assembly, and quality control. Their high precision and force output make them ideal for tasks that require accurate positioning and consistent performance. For instance, in automated welding systems, linear motors ensure precise control of the welding head, resulting in high-quality welds and increased production efficiency. Additionally, linear motors are used in the testing and inspection of automotive components, where their precise motion control helps in detecting defects and ensuring product quality. In the healthcare sector, linear drive linear motors are integral to the operation of advanced medical equipment. They are used in medical imaging devices such as MRI and CT scanners, where their smooth and precise motion is essential for obtaining high-resolution images. Linear motors are also employed in robotic surgery systems, where their accuracy and responsiveness enable surgeons to perform delicate procedures with minimal invasiveness. Furthermore, linear motors are used in laboratory automation systems, where they facilitate the precise handling and processing of samples, leading to increased efficiency and accuracy in diagnostic testing. The aerospace industry also relies on linear drive linear motors for various applications. These motors are used in flight simulators to provide realistic motion feedback, enhancing pilot training and safety. In satellite positioning systems, linear motors ensure precise control of satellite components, enabling accurate positioning and communication. Additionally, linear motors are used in the manufacturing of aerospace components, where their high precision and force output are essential for producing parts that meet stringent quality standards. The ability of linear motors to operate in harsh environments and withstand extreme conditions makes them suitable for aerospace applications. National defense applications benefit from the robustness and precision of linear drive linear motors. These motors are used in missile guidance systems, where their accurate motion control ensures precise targeting and navigation. In military vehicle automation, linear motors provide reliable and efficient control of various vehicle systems, enhancing operational capabilities and reducing the need for manual intervention. Additionally, linear motors are used in advanced surveillance equipment, where their smooth and precise motion enables accurate tracking and monitoring of targets. In industrial manufacturing, linear drive linear motors are used in a wide range of applications, from material handling and packaging to CNC machinery and robotic arms. Their high force output and precision make them ideal for tasks that require accurate positioning and consistent performance. For example, in CNC machinery, linear motors provide precise control of the cutting tool, resulting in high-quality machined parts. In robotic arms, linear motors enable smooth and accurate movement, enhancing the efficiency and flexibility of automated manufacturing processes. Overall, the versatility and performance of linear drive linear motors make them a valuable asset in various industries, driving innovation and improving operational efficiency.

Global Linear Drive Linear Motor Market Outlook:

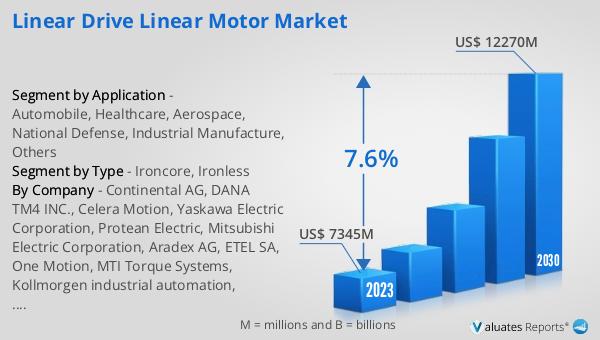

The global Linear Drive Linear Motor market was valued at US$ 7345 million in 2023 and is anticipated to reach US$ 12270 million by 2030, witnessing a CAGR of 7.6% during the forecast period 2024-2030. This market growth reflects the increasing demand for high-precision and efficient motion control solutions across various industries. The automotive, healthcare, aerospace, national defense, and industrial manufacturing sectors are all contributing to this growth by adopting linear drive linear motors for their advanced capabilities. These motors offer significant advantages in terms of precision, force output, and operational smoothness, making them essential components in modern automation and manufacturing processes. As industries continue to evolve and embrace new technologies, the demand for linear drive linear motors is expected to rise, driving further innovation and development in this market. The projected growth of the market underscores the importance of linear drive linear motors in enhancing productivity, efficiency, and quality across a wide range of applications.

| Report Metric | Details |

| Report Name | Linear Drive Linear Motor Market |

| Accounted market size in 2023 | US$ 7345 million |

| Forecasted market size in 2030 | US$ 12270 million |

| CAGR | 7.6% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Continental AG, DANA TM4 INC., Celera Motion, Yaskawa Electric Corporation, Protean Electric, Mitsubishi Electric Corporation, Aradex AG, ETEL SA, One Motion, MTI Torque Systems, Kollmorgen industrial automation, Ingenia Cat SL, Fisher&Paykel Technologies, NTI AG LinMot |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |