What is Global Insulated Box Foundry Service Market?

The Global Insulated Box Foundry Service Market is a specialized sector that focuses on the production and supply of insulated boxes used for various applications. These insulated boxes are designed to maintain temperature-sensitive products at a consistent temperature during storage and transportation. The market encompasses a wide range of industries, including pharmaceuticals, food and beverages, chemicals, and consumer goods, where temperature control is crucial. The insulated boxes are made from materials such as expanded polystyrene (EPS), polyurethane, and other advanced insulating materials that provide superior thermal protection. The market is driven by the increasing demand for temperature-sensitive products, stringent regulations regarding the transportation of perishable goods, and the growing awareness about the importance of maintaining product integrity. Companies operating in this market offer a variety of services, including custom design, manufacturing, and logistics support to meet the specific needs of their clients. The market is characterized by continuous innovation and advancements in insulation technology to enhance the performance and efficiency of insulated boxes.

Pure Foundry Model, IDM Foundry Model in the Global Insulated Box Foundry Service Market:

The Pure Foundry Model and IDM Foundry Model are two distinct approaches within the Global Insulated Box Foundry Service Market. The Pure Foundry Model refers to companies that exclusively focus on the manufacturing and supply of insulated boxes without engaging in the design or development of the products that will be stored or transported in these boxes. These companies operate as third-party manufacturers, providing high-quality insulated boxes to various industries based on the specifications provided by their clients. They invest heavily in advanced manufacturing technologies and materials to ensure that their products meet the stringent requirements of temperature-sensitive applications. On the other hand, the IDM (Integrated Device Manufacturer) Foundry Model involves companies that not only manufacture insulated boxes but also engage in the design, development, and testing of the products that will be stored or transported in these boxes. These companies offer end-to-end solutions, including product design, material selection, manufacturing, and logistics support. They work closely with their clients to understand their specific needs and develop customized solutions that ensure the safe and efficient transportation of temperature-sensitive products. The IDM Foundry Model allows for greater control over the entire supply chain, from product development to delivery, ensuring that the insulated boxes are perfectly suited to the requirements of the products they will contain. Both models have their advantages and are chosen based on the specific needs and capabilities of the companies involved. The Pure Foundry Model offers flexibility and cost-effectiveness, as companies can focus solely on manufacturing without the need for extensive R&D investments. This model is ideal for companies that require high-quality insulated boxes but do not have the resources or expertise to develop them in-house. The IDM Foundry Model, on the other hand, provides a comprehensive solution that ensures the highest level of product integrity and performance. This model is suitable for companies that require a high degree of customization and control over the entire supply chain. In the Global Insulated Box Foundry Service Market, both models coexist, catering to the diverse needs of various industries and applications. Companies may choose one model over the other based on factors such as cost, expertise, and the level of control required over the product development process.

Consumer Grade Products, Medical Grade Products in the Global Insulated Box Foundry Service Market:

The Global Insulated Box Foundry Service Market plays a crucial role in various sectors, including consumer-grade products and medical-grade products. In the realm of consumer-grade products, insulated boxes are widely used for the transportation and storage of perishable goods such as food and beverages. These boxes help maintain the freshness and quality of products by providing a controlled temperature environment, preventing spoilage and extending shelf life. For instance, insulated boxes are commonly used in the delivery of groceries, meal kits, and other perishable items, ensuring that they reach consumers in optimal condition. The growing demand for online grocery shopping and home delivery services has further fueled the need for reliable insulated packaging solutions. In the medical-grade products sector, insulated boxes are essential for the safe transportation and storage of temperature-sensitive pharmaceuticals, vaccines, and biological samples. These products require strict temperature control to maintain their efficacy and safety. Insulated boxes used in the medical field are designed to meet stringent regulatory standards and provide superior thermal protection. They are often equipped with advanced features such as temperature monitoring and data logging to ensure that the products remain within the required temperature range throughout the supply chain. The COVID-19 pandemic has highlighted the importance of reliable insulated packaging solutions for the distribution of vaccines and other critical medical supplies. The Global Insulated Box Foundry Service Market has responded to this demand by developing innovative and high-performance insulated boxes that meet the specific needs of the medical industry. Overall, the market's ability to provide customized and reliable insulated packaging solutions has made it an indispensable part of both the consumer and medical sectors.

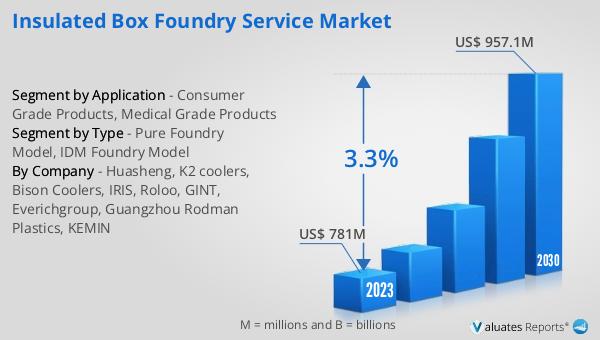

Global Insulated Box Foundry Service Market Outlook:

The global Insulated Box Foundry Service market was valued at US$ 781 million in 2023 and is anticipated to reach US$ 957.1 million by 2030, witnessing a CAGR of 3.3% during the forecast period 2024-2030. This market growth is driven by the increasing demand for temperature-sensitive products across various industries, including pharmaceuticals, food and beverages, and chemicals. The need for reliable and efficient insulated packaging solutions has become more critical as companies strive to maintain the integrity and quality of their products during transportation and storage. The market is characterized by continuous innovation and advancements in insulation technology, which enhance the performance and efficiency of insulated boxes. Companies operating in this market are investing in research and development to develop new materials and designs that provide superior thermal protection. Additionally, the growing awareness about the importance of maintaining product integrity and complying with regulatory standards is further driving the demand for high-quality insulated boxes. The market's ability to offer customized solutions tailored to the specific needs of different industries has also contributed to its growth. Overall, the Global Insulated Box Foundry Service Market is poised for steady growth, driven by the increasing demand for temperature-sensitive products and the continuous advancements in insulation technology.

| Report Metric | Details |

| Report Name | Insulated Box Foundry Service Market |

| Accounted market size in 2023 | US$ 781 million |

| Forecasted market size in 2030 | US$ 957.1 million |

| CAGR | 3.3% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Huasheng, K2 coolers, Bison Coolers, IRIS, Roloo, GINT, Everichgroup, Guangzhou Rodman Plastics, KEMIN |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |