What is Global Hot Isostatic Pressing System Market?

The Global Hot Isostatic Pressing (HIP) System Market is a specialized segment within the broader manufacturing and materials processing industry. Hot Isostatic Pressing is a technique used to enhance the properties of materials, such as metals and ceramics, by applying high pressure and temperature uniformly in all directions. This process helps to eliminate internal voids, improve mechanical properties, and achieve near-net shape components. The market for HIP systems is driven by the increasing demand for high-performance materials in various industries, including aerospace, automotive, medical, and energy. These systems are essential for producing components that require high strength, durability, and precision. The global market for HIP systems is characterized by technological advancements, increasing adoption in emerging economies, and a growing focus on sustainable manufacturing practices. As industries continue to seek ways to improve material performance and reduce production costs, the demand for HIP systems is expected to grow.

Small HIP Systems, Medium HIP System, Large HIP System in the Global Hot Isostatic Pressing System Market:

Small HIP Systems, Medium HIP Systems, and Large HIP Systems are categorized based on their size and capacity, each serving different industrial needs within the Global Hot Isostatic Pressing System Market. Small HIP Systems are typically used for research and development purposes, as well as for the production of small, high-precision components. These systems are ideal for laboratories and small-scale manufacturing units where space and budget constraints are significant considerations. They offer the flexibility to experiment with different materials and processes, making them invaluable for innovation and prototyping. Medium HIP Systems, on the other hand, are designed for mid-sized production runs and are commonly used in industries such as aerospace, automotive, and medical devices. These systems strike a balance between capacity and cost, providing a versatile solution for companies that need to produce medium-sized batches of components with consistent quality. They are often used for the production of turbine blades, medical implants, and automotive parts, where the demand for high-performance materials is critical. Large HIP Systems are the workhorses of the HIP market, designed for mass production and large-scale industrial applications. These systems are capable of processing large volumes of materials and are used in industries such as oil and gas, power generation, and heavy machinery. Large HIP Systems are essential for producing large, complex components that require uniform material properties and high structural integrity. They are often used for the production of large castings, forgings, and structural components that are subjected to extreme operating conditions. The choice between small, medium, and large HIP systems depends on various factors, including the specific application, production volume, budget, and space constraints. Each type of system offers unique advantages and is tailored to meet the diverse needs of different industries. As the demand for high-performance materials continues to grow, the market for HIP systems is expected to expand, with advancements in technology further enhancing their capabilities and efficiency.

Metallurgical, Aerospace, Oil&Gas, Automobile, Research, Other in the Global Hot Isostatic Pressing System Market:

The usage of Global Hot Isostatic Pressing (HIP) Systems spans across various industries, including Metallurgical, Aerospace, Oil & Gas, Automobile, Research, and others, each benefiting from the unique advantages offered by this technology. In the Metallurgical industry, HIP systems are used to improve the properties of metals and alloys, making them stronger, more durable, and resistant to wear and corrosion. This is particularly important for applications such as tool manufacturing, where high-performance materials are essential for cutting, shaping, and forming operations. In the Aerospace industry, HIP systems are critical for producing components that must withstand extreme conditions, such as high temperatures and pressures. Turbine blades, engine components, and structural parts are often manufactured using HIP technology to ensure they meet stringent performance and safety standards. The Oil & Gas industry also relies on HIP systems to produce components that can endure harsh environments, such as deep-sea drilling and high-pressure pipelines. Valves, pumps, and other critical parts are often subjected to HIP processing to enhance their reliability and longevity. In the Automobile industry, HIP systems are used to manufacture high-performance parts, such as engine components, transmission gears, and suspension parts. These components require exceptional strength and durability to ensure the safety and performance of vehicles. Research institutions and laboratories use HIP systems for material development and testing, exploring new alloys and composites with enhanced properties. This research is crucial for advancing technology and discovering new applications for HIP-processed materials. Other industries, such as medical devices and electronics, also benefit from HIP technology. Medical implants, such as hip and knee replacements, are often manufactured using HIP systems to ensure biocompatibility and long-term performance. In the electronics industry, HIP systems are used to produce components with precise dimensions and superior electrical properties. The versatility and effectiveness of HIP systems make them indispensable across a wide range of applications, driving innovation and improving the quality and performance of materials and components.

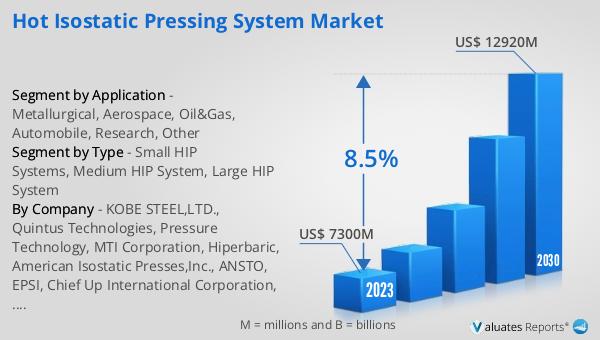

Global Hot Isostatic Pressing System Market Outlook:

The global Hot Isostatic Pressing (HIP) System market was valued at US$ 7,300 million in 2023 and is projected to reach US$ 12,920 million by 2030, reflecting a Compound Annual Growth Rate (CAGR) of 8.5% during the forecast period from 2024 to 2030. This significant growth is driven by the increasing demand for high-performance materials across various industries, including aerospace, automotive, medical, and energy. The HIP process, which involves applying high pressure and temperature uniformly to materials, enhances their mechanical properties, making them stronger, more durable, and resistant to wear and corrosion. As industries continue to seek ways to improve material performance and reduce production costs, the adoption of HIP systems is expected to rise. Technological advancements and the growing focus on sustainable manufacturing practices are also contributing to the market's expansion. The projected growth underscores the importance of HIP systems in modern manufacturing and their potential to drive innovation and efficiency in material processing.

| Report Metric | Details |

| Report Name | Hot Isostatic Pressing System Market |

| Accounted market size in 2023 | US$ 7300 million |

| Forecasted market size in 2030 | US$ 12920 million |

| CAGR | 8.5% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | KOBE STEEL,LTD., Quintus Technologies, Pressure Technology, MTI Corporation, Hiperbaric, American Isostatic Presses,Inc., ANSTO, EPSI, Chief Up International Corporation, PTC Industries, OMCD Group, Hasmak, NEUMAN&ESSE |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |