What is Global Hollow Blow Molding Machine Market?

The Global Hollow Blow Molding Machine Market refers to the industry focused on the production and sale of machines used to create hollow plastic products through blow molding techniques. These machines are essential in manufacturing a wide range of plastic containers and products, such as bottles, drums, and tanks, by inflating a heated plastic tube until it conforms to the shape of a mold. The market encompasses various types of blow molding machines, including extrusion blow molding machines, injection blow molding machines, and others, each catering to different manufacturing needs and product specifications. The demand for these machines is driven by their extensive applications across multiple industries, including food and beverage, chemicals, pharmaceuticals, and cosmetics. As industries continue to seek efficient and cost-effective methods for producing high-quality plastic products, the global hollow blow molding machine market is expected to see sustained growth and innovation.

Extrusion Blow Molding Machine, Injection Blow Molding Machine, Others in the Global Hollow Blow Molding Machine Market:

Extrusion Blow Molding Machines are a significant segment within the Global Hollow Blow Molding Machine Market. These machines work by extruding a molten plastic tube, known as a parison, which is then clamped into a mold and inflated to form the desired shape. This method is particularly suited for producing large, hollow objects like bottles, containers, and automotive parts. The versatility and efficiency of extrusion blow molding make it a popular choice for manufacturers looking to produce high volumes of uniform products. On the other hand, Injection Blow Molding Machines combine the processes of injection molding and blow molding. In this method, plastic is first injected into a preform mold to create a solid preform, which is then transferred to a blow mold where it is inflated to form the final product. This technique is ideal for producing small, precise containers with excellent surface finish and dimensional accuracy, such as pharmaceutical bottles and cosmetic containers. The precision and quality control offered by injection blow molding make it the largest segment in the market. Other types of blow molding machines include stretch blow molding machines, which are used to produce high-strength, lightweight containers by stretching the plastic both axially and radially. This method is commonly used for making PET bottles for beverages. Each type of blow molding machine has its unique advantages and applications, catering to the diverse needs of various industries. The continuous advancements in blow molding technology, such as improved automation and energy efficiency, further enhance the capabilities and appeal of these machines in the global market.

Food and Beverage Industrial, Chemical Industrial, Pharmaceutical Industrial, Cosmetics Industrial, Others in the Global Hollow Blow Molding Machine Market:

The Global Hollow Blow Molding Machine Market finds extensive usage across several key industries, each benefiting from the unique capabilities of blow molding technology. In the Food and Beverage Industry, these machines are crucial for producing a wide range of packaging solutions, including bottles for water, juices, and dairy products, as well as containers for sauces and condiments. The ability to produce lightweight, durable, and cost-effective packaging makes blow molding machines indispensable in this sector. In the Chemical Industry, blow molding machines are used to manufacture containers for storing and transporting various chemicals, including hazardous substances. The precision and reliability of these machines ensure that the containers meet stringent safety and quality standards, preventing leaks and contamination. The Pharmaceutical Industry also relies heavily on blow molding machines for producing sterile and secure packaging for medicines, syrups, and other pharmaceutical products. The high level of hygiene and accuracy required in this industry makes injection blow molding machines particularly suitable. In the Cosmetics Industry, blow molding machines are used to create aesthetically pleasing and functional packaging for products such as shampoos, lotions, and creams. The ability to produce intricate shapes and designs helps brands differentiate their products in a competitive market. Additionally, other industries, such as automotive and household goods, utilize blow molding machines to manufacture various components and products, including fuel tanks, air ducts, and storage containers. The versatility and efficiency of blow molding technology make it a valuable asset across these diverse applications, driving the demand for hollow blow molding machines globally.

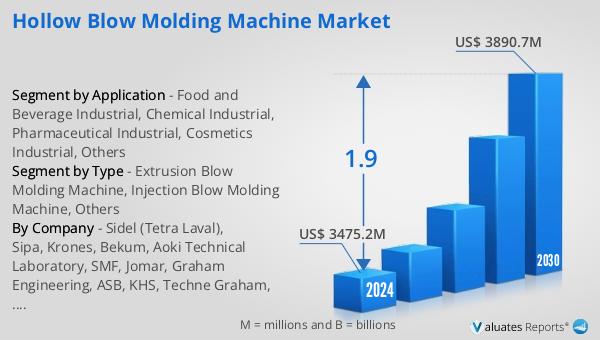

Global Hollow Blow Molding Machine Market Outlook:

The global Hollow Blow Molding Machine market is projected to grow from US$ 3475.2 million in 2024 to US$ 3890.7 million by 2030 at a Compound Annual Growth Rate (CAGR) of 1.9% during the forecast period. Global top five manufacturers hold a share over 30%. Europe is the largest market with a share about 40% followed by China and Asia Pacific Ex China both have a share over 40 percent. In terms of product, Injection Blow Molding Machine is the largest segment with a share over 65%.

| Report Metric | Details |

| Report Name | Hollow Blow Molding Machine Market |

| Accounted market size in 2024 | US$ 3475.2 million |

| Forecasted market size in 2030 | US$ 3890.7 million |

| CAGR | 1.9 |

| Base Year | 2024 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Sales by Region |

|

| By Company | Sidel (Tetra Laval), Sipa, Krones, Bekum, Aoki Technical Laboratory, SMF, Jomar, Graham Engineering, ASB, KHS, Techne Graham, Uniloy Milacron (Milacron), Mauser, Automa, Chia Ming Machinery, Fong Kee, ZQ Machinery, Akei, JASU Group, Quinko, Tech-Long, Parker, Magic, Kautex (Textron), BBM, Meccanoplastica, Plastiblow, Pavan Zanetti, Wilmington, Multipack, Sabmann, Newamstar, Guangdong Leshan Machinery |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |