What is Global Heat Exchanger for Hydrogen Station Market?

The global Heat Exchanger for Hydrogen Station market is a rapidly evolving sector that focuses on the development and deployment of heat exchangers specifically designed for hydrogen refueling stations. These stations are crucial for the hydrogen economy, as they facilitate the refueling of hydrogen-powered vehicles. Heat exchangers play a vital role in these stations by managing the thermal energy during the hydrogen compression and dispensing processes. They ensure that the hydrogen gas is at the optimal temperature for safe and efficient refueling. The market is driven by the increasing adoption of hydrogen as a clean energy source, advancements in hydrogen infrastructure, and the growing number of hydrogen-powered vehicles. As countries and companies invest in hydrogen technology to reduce carbon emissions, the demand for efficient and reliable heat exchangers in hydrogen stations is expected to rise significantly. This market encompasses various types of heat exchangers, including plate and tube heat exchangers, each with its specific applications and advantages. The global Heat Exchanger for Hydrogen Station market is poised for substantial growth, reflecting the broader trend towards sustainable and renewable energy solutions.

Plate Heat Exchanger, Tube Heat Exchanger in the Global Heat Exchanger for Hydrogen Station Market:

Plate heat exchangers and tube heat exchangers are two primary types of heat exchangers used in the global Heat Exchanger for Hydrogen Station market. Plate heat exchangers consist of multiple thin, corrugated plates stacked together, creating a series of channels through which fluids can flow. These plates are typically made of stainless steel or other corrosion-resistant materials, ensuring durability and longevity. The design of plate heat exchangers allows for a large surface area in a compact space, making them highly efficient in transferring heat between fluids. They are particularly suitable for applications where space is limited, and high thermal efficiency is required. On the other hand, tube heat exchangers, also known as shell and tube heat exchangers, consist of a series of tubes enclosed within a cylindrical shell. One fluid flows through the tubes, while the other fluid flows around the tubes within the shell. This design allows for high-pressure applications and is ideal for handling large volumes of fluids. Tube heat exchangers are known for their robustness and ability to operate under extreme conditions, making them suitable for hydrogen stations that require high reliability and performance. Both types of heat exchangers have their unique advantages and are selected based on the specific requirements of the hydrogen station. Plate heat exchangers are often preferred for their compact size and high efficiency, while tube heat exchangers are chosen for their durability and capacity to handle high pressures. In the context of hydrogen stations, these heat exchangers are essential for maintaining the optimal temperature of hydrogen gas during compression and dispensing, ensuring safe and efficient refueling. The choice between plate and tube heat exchangers depends on factors such as the station's design, operational requirements, and budget. As the global Heat Exchanger for Hydrogen Station market continues to grow, advancements in heat exchanger technology are expected to further enhance the performance and efficiency of hydrogen refueling stations.

35MPa Hydrogen Station, 70MPa Hydrogen Station in the Global Heat Exchanger for Hydrogen Station Market:

The usage of global heat exchangers for hydrogen stations is critical in both 35MPa and 70MPa hydrogen stations. In a 35MPa hydrogen station, the heat exchanger's primary role is to manage the thermal energy during the hydrogen compression process. Hydrogen gas needs to be compressed to high pressures for storage and dispensing, and this compression generates significant heat. The heat exchanger helps dissipate this heat, ensuring that the hydrogen gas remains at a safe and optimal temperature for refueling. This is crucial for maintaining the integrity of the storage tanks and the safety of the refueling process. In a 70MPa hydrogen station, the role of the heat exchanger becomes even more critical due to the higher pressures involved. At 70MPa, the hydrogen gas is compressed to a much higher pressure, which generates even more heat. The heat exchanger must efficiently manage this thermal energy to prevent overheating and ensure the hydrogen gas is at the correct temperature for dispensing. This is essential for the safety and efficiency of the refueling process, as well as for the longevity of the station's equipment. Both 35MPa and 70MPa hydrogen stations rely on heat exchangers to maintain the thermal balance during the compression and dispensing processes. The choice of heat exchanger, whether plate or tube, depends on the specific requirements of the station, including the pressure levels, space constraints, and desired efficiency. Plate heat exchangers are often preferred for their compact size and high thermal efficiency, making them suitable for stations with limited space. Tube heat exchangers, on the other hand, are chosen for their robustness and ability to handle high pressures, making them ideal for 70MPa stations. The efficient operation of heat exchangers in hydrogen stations is crucial for the overall performance and safety of the hydrogen refueling infrastructure. As the demand for hydrogen-powered vehicles increases, the need for reliable and efficient heat exchangers in hydrogen stations will continue to grow. This will drive further advancements in heat exchanger technology, enhancing the performance and efficiency of hydrogen refueling stations worldwide.

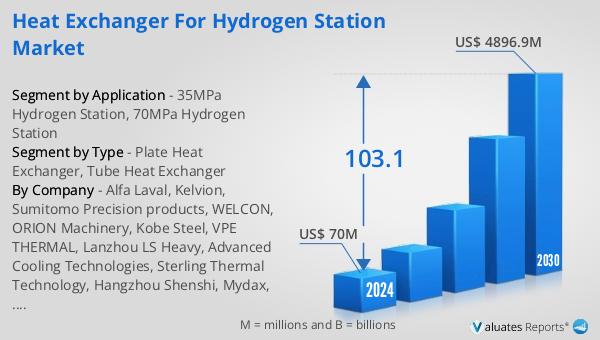

Global Heat Exchanger for Hydrogen Station Market Outlook:

The global Heat Exchanger for Hydrogen Station market is anticipated to expand significantly, growing from US$ 70 million in 2024 to US$ 4896.9 million by 2030, with a remarkable Compound Annual Growth Rate (CAGR) of 103.1% during the forecast period. Leading manufacturers in this market include Alfa Laval, Kelvin, Sumitomo Precision Products, WELCON, ORION Machinery, Kobe Steel, VPE THERMAL, Lanzhou LS Heavy, and Advanced Cooling Technologies. Among these, the top five manufacturers collectively hold over 60% of the market share, with Alfa Laval being the largest producer. Currently, Japan stands as the largest production region, accounting for approximately 40% of the market share, followed by China and Europe. This growth is driven by the increasing adoption of hydrogen as a clean energy source and the expansion of hydrogen infrastructure globally. The market's rapid expansion reflects the broader trend towards sustainable and renewable energy solutions, highlighting the critical role of heat exchangers in the hydrogen economy. As countries and companies invest in hydrogen technology to reduce carbon emissions, the demand for efficient and reliable heat exchangers in hydrogen stations is expected to rise significantly. This market encompasses various types of heat exchangers, including plate and tube heat exchangers, each with its specific applications and advantages. The global Heat Exchanger for Hydrogen Station market is poised for substantial growth, reflecting the broader trend towards sustainable and renewable energy solutions.

| Report Metric | Details |

| Report Name | Heat Exchanger for Hydrogen Station Market |

| Accounted market size in 2024 | US$ 70 in million |

| Forecasted market size in 2030 | US$ 4896.9 million |

| CAGR | 103.1 |

| Base Year | 2024 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Sales by Region |

|

| By Company | Alfa Laval, Kelvion, Sumitomo Precision products, WELCON, ORION Machinery, Kobe Steel, VPE THERMAL, Lanzhou LS Heavy, Advanced Cooling Technologies, Sterling Thermal Technology, Hangzhou Shenshi, Mydax, SureHydrogen |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |