What is Global Food Safety Lab Automation Market?

The Global Food Safety Lab Automation Market refers to the integration of advanced technologies and automated systems in laboratories to ensure the safety and quality of food products. This market encompasses a wide range of automated solutions, including robotic systems, software, and instruments designed to streamline and enhance the efficiency of food safety testing processes. The primary goal of lab automation in this context is to reduce human error, increase throughput, and ensure consistent and accurate results. By automating repetitive and time-consuming tasks, laboratories can focus on more complex analyses and improve overall productivity. The market is driven by the increasing demand for safe and high-quality food products, stringent regulatory requirements, and the need for faster and more reliable testing methods. As food safety concerns continue to rise globally, the adoption of lab automation technologies is expected to grow, providing significant benefits to food manufacturers, regulatory bodies, and consumers alike.

Food Safety Testing, Food Authenticity Testing, Food Shelf Life Testing in the Global Food Safety Lab Automation Market:

Food safety testing is a critical component of the Global Food Safety Lab Automation Market, ensuring that food products are free from harmful contaminants and meet regulatory standards. This process involves the use of automated systems to detect and quantify pathogens, toxins, and other hazardous substances in food samples. Automated food safety testing offers several advantages, including increased accuracy, faster turnaround times, and reduced labor costs. By leveraging advanced technologies such as high-throughput screening and real-time PCR, laboratories can efficiently identify potential risks and take corrective actions to prevent foodborne illnesses. Food authenticity testing, on the other hand, focuses on verifying the origin and composition of food products to prevent fraud and ensure compliance with labeling regulations. Automated systems can analyze the molecular and chemical properties of food samples, providing reliable data on their authenticity. This is particularly important in the context of global supply chains, where the risk of food fraud is higher. Food shelf life testing is another crucial aspect of the market, aimed at determining the stability and longevity of food products under various storage conditions. Automated systems can simulate different environmental factors, such as temperature and humidity, to assess the shelf life of food items accurately. This information is vital for manufacturers to optimize packaging, storage, and distribution processes, ultimately reducing food waste and ensuring product quality. Overall, the integration of automation in food safety, authenticity, and shelf life testing enhances the reliability and efficiency of these processes, contributing to the overall safety and quality of the global food supply.

Dairy Products, Cereals, Meat & Seafood, Manufactured Food, Drinks, Animal Feed, Fruits and Vegetables, Other in the Global Food Safety Lab Automation Market:

The usage of Global Food Safety Lab Automation Market spans across various sectors, including dairy products, cereals, meat and seafood, manufactured food, drinks, animal feed, fruits and vegetables, and others. In the dairy industry, automated systems are employed to test for contaminants such as pathogens, antibiotics, and mycotoxins, ensuring that milk and dairy products are safe for consumption. These systems also help in monitoring the quality and consistency of dairy products, enhancing consumer trust. In the cereals sector, lab automation is used to detect pesticide residues, heavy metals, and other contaminants that may pose health risks. Automated testing ensures that cereals meet safety standards and are free from harmful substances. For meat and seafood, lab automation plays a crucial role in detecting pathogens like Salmonella and E. coli, as well as chemical contaminants such as antibiotics and heavy metals. This ensures that meat and seafood products are safe for consumption and comply with regulatory requirements. In the manufactured food sector, automated systems are used to test for a wide range of contaminants, including allergens, pathogens, and chemical residues. This helps manufacturers maintain high safety standards and avoid costly recalls. The drinks industry also benefits from lab automation, with automated systems used to test for contaminants such as pesticides, heavy metals, and microbial pathogens in beverages. This ensures that drinks are safe for consumption and meet quality standards. In the animal feed sector, lab automation is used to test for contaminants such as mycotoxins, pathogens, and heavy metals, ensuring that feed is safe for livestock and does not pose a risk to the food chain. For fruits and vegetables, automated systems are employed to detect pesticide residues, pathogens, and other contaminants, ensuring that fresh produce is safe for consumption. Overall, the integration of lab automation in these sectors enhances the efficiency and reliability of food safety testing, contributing to the overall safety and quality of the global food supply.

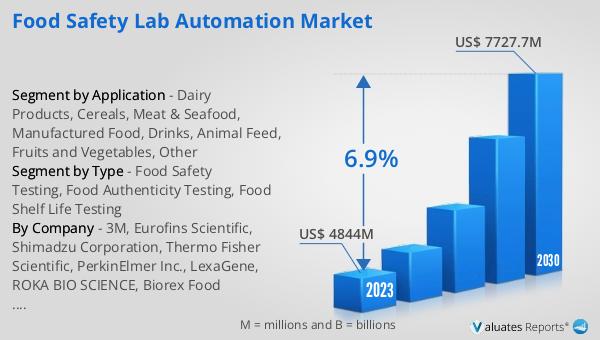

Global Food Safety Lab Automation Market Outlook:

The global Food Safety Lab Automation market was valued at US$ 4844 million in 2023 and is anticipated to reach US$ 7727.7 million by 2030, witnessing a CAGR of 6.9% during the forecast period 2024-2030. This significant growth reflects the increasing demand for advanced technologies and automated systems in food safety testing. As food safety concerns continue to rise globally, the adoption of lab automation technologies is expected to grow, providing significant benefits to food manufacturers, regulatory bodies, and consumers alike. The market is driven by the need for faster, more reliable testing methods, and the desire to reduce human error and increase throughput in laboratories. By automating repetitive and time-consuming tasks, laboratories can focus on more complex analyses and improve overall productivity. The integration of automation in food safety, authenticity, and shelf life testing enhances the reliability and efficiency of these processes, contributing to the overall safety and quality of the global food supply. As a result, the Global Food Safety Lab Automation Market is poised for substantial growth in the coming years, driven by the increasing demand for safe and high-quality food products and stringent regulatory requirements.

| Report Metric | Details |

| Report Name | Food Safety Lab Automation Market |

| Accounted market size in 2023 | US$ 4844 million |

| Forecasted market size in 2030 | US$ 7727.7 million |

| CAGR | 6.9% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | 3M, Eurofins Scientific, Shimadzu Corporation, Thermo Fisher Scientific, PerkinElmer Inc., LexaGene, ROKA BIO SCIENCE, Biorex Food Diagnostics, Randox Food Diagnostics, Romer Labs, SGS, Clear Labs, Neogen, Barentz International BV, bioMérieux,Inc., Tetra Pak |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |