What is Global Engineering Vehicle Machine Control Market?

The Global Engineering Vehicle Machine Control Market refers to the industry that focuses on the development, production, and implementation of advanced control systems for engineering vehicles. These vehicles include excavators, dozers, graders, and other heavy machinery used in construction, mining, and other industrial applications. The primary goal of machine control systems is to enhance the efficiency, accuracy, and safety of these vehicles by integrating technologies such as GPS, sensors, and software. These systems enable operators to perform tasks with greater precision, reducing the need for manual intervention and minimizing errors. The market for these advanced control systems is driven by the increasing demand for automation in construction and mining activities, as well as the need for improved productivity and cost-effectiveness. As a result, the Global Engineering Vehicle Machine Control Market is expected to witness significant growth in the coming years, with advancements in technology and increasing adoption of these systems across various industries.

2D Type, 3D Type in the Global Engineering Vehicle Machine Control Market:

The Global Engineering Vehicle Machine Control Market can be categorized into two main types: 2D and 3D machine control systems. 2D machine control systems are designed to provide basic guidance and control for engineering vehicles. These systems use sensors and GPS technology to help operators maintain the correct grade and alignment while performing tasks such as excavation, grading, and leveling. 2D systems are relatively simple and cost-effective, making them suitable for smaller projects and less complex applications. They provide real-time feedback to the operator, allowing for adjustments to be made on the fly, which helps improve accuracy and efficiency. On the other hand, 3D machine control systems offer a more advanced level of control and precision. These systems use a combination of GPS, sensors, and sophisticated software to create a three-dimensional model of the worksite. This model allows operators to visualize the entire project and make more informed decisions. 3D systems are particularly useful for large-scale projects and complex tasks that require a high degree of accuracy, such as road construction, bridge building, and large-scale earthmoving. The integration of 3D technology enables operators to work more efficiently, reducing the need for rework and minimizing material waste. Additionally, 3D machine control systems can be integrated with Building Information Modeling (BIM) software, allowing for seamless collaboration between different stakeholders and improving overall project management. Both 2D and 3D machine control systems play a crucial role in enhancing the performance of engineering vehicles, but the choice between the two depends on the specific requirements of the project and the level of precision needed. As technology continues to advance, we can expect to see further improvements in both 2D and 3D machine control systems, making them even more effective and user-friendly.

Excavators, Dozers, Graders, Others in the Global Engineering Vehicle Machine Control Market:

The usage of Global Engineering Vehicle Machine Control Market systems in various types of machinery such as excavators, dozers, graders, and others has revolutionized the construction and mining industries. Excavators, for instance, benefit greatly from machine control systems as they allow operators to dig with precision and efficiency. By using GPS and sensors, these systems provide real-time data on the position and depth of the excavator's bucket, ensuring that the excavation is done accurately according to the project specifications. This not only speeds up the excavation process but also reduces the risk of over-digging or under-digging, which can lead to costly rework. Dozers, which are used for pushing large quantities of soil, sand, or other materials, also see significant improvements with machine control systems. These systems help operators maintain the correct blade angle and height, ensuring that the material is moved efficiently and evenly. This results in a smoother and more level surface, which is crucial for the subsequent stages of construction. Graders, which are used for fine grading and leveling, benefit from the high precision offered by machine control systems. These systems enable operators to achieve the desired grade with minimal effort, reducing the need for manual adjustments and rework. The real-time feedback provided by the system ensures that the grading is done accurately, leading to a higher quality finished product. Other types of machinery, such as compactors and pavers, also benefit from machine control systems. Compactors, for example, can use these systems to ensure that the soil or asphalt is compacted to the correct density, which is essential for the stability and longevity of the construction. Pavers can use machine control systems to lay asphalt or concrete with precision, ensuring a smooth and even surface. Overall, the integration of machine control systems in various types of engineering vehicles has led to significant improvements in efficiency, accuracy, and safety. These systems have become an essential tool for modern construction and mining projects, helping to reduce costs, minimize errors, and improve overall project outcomes.

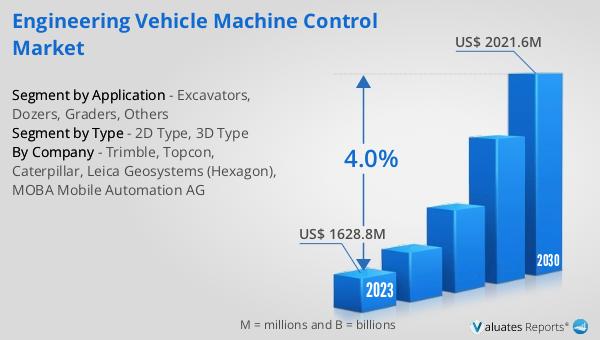

Global Engineering Vehicle Machine Control Market Outlook:

The global Engineering Vehicle Machine Control market was valued at US$ 1628.8 million in 2023 and is anticipated to reach US$ 2021.6 million by 2030, witnessing a CAGR of 4.0% during the forecast period 2024-2030. This market growth can be attributed to the increasing demand for automation and precision in construction and mining activities. As industries continue to adopt advanced technologies to improve efficiency and reduce costs, the demand for machine control systems is expected to rise. These systems offer numerous benefits, including enhanced accuracy, reduced material waste, and improved safety, making them an attractive investment for companies in the construction and mining sectors. Additionally, the integration of machine control systems with other technologies, such as Building Information Modeling (BIM) and Internet of Things (IoT), is expected to further drive market growth. As a result, the Global Engineering Vehicle Machine Control Market is poised for significant expansion in the coming years, with advancements in technology and increasing adoption across various industries.

| Report Metric | Details |

| Report Name | Engineering Vehicle Machine Control Market |

| Accounted market size in 2023 | US$ 1628.8 million |

| Forecasted market size in 2030 | US$ 2021.6 million |

| CAGR | 4.0% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Trimble, Topcon, Caterpillar, Leica Geosystems (Hexagon), MOBA Mobile Automation AG |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |