What is Global 2D Engineering Vehicle Machine Control Market?

The Global 2D Engineering Vehicle Machine Control Market refers to the industry focused on the development, production, and implementation of 2D machine control systems for engineering vehicles. These systems are designed to enhance the precision and efficiency of construction and earthmoving equipment by providing real-time data and guidance to operators. The technology typically involves the use of sensors, GPS, and software to create a two-dimensional map of the worksite, allowing operators to follow precise plans and make adjustments as needed. This market is crucial for improving productivity, reducing operational costs, and ensuring the accuracy of construction projects. The adoption of 2D machine control systems is driven by the need for increased efficiency and accuracy in construction and earthmoving operations, as well as the growing demand for advanced technology in the construction industry.

Software, Hardware in the Global 2D Engineering Vehicle Machine Control Market:

In the Global 2D Engineering Vehicle Machine Control Market, both software and hardware components play critical roles in the functionality and effectiveness of the systems. The hardware aspect includes various sensors, GPS units, and control panels that are installed on the engineering vehicles. These sensors and GPS units collect real-time data about the vehicle's position and the surrounding environment, which is then processed by the control panels to provide guidance to the operator. The hardware must be robust and durable to withstand the harsh conditions of construction sites, including extreme temperatures, dust, and vibrations. On the other hand, the software component is equally important as it processes the data collected by the hardware and translates it into actionable information for the operator. The software typically includes mapping and design tools that allow operators to create and follow precise plans for their work. It also includes user interfaces that are designed to be intuitive and easy to use, ensuring that operators can quickly understand and act on the information provided. Additionally, the software often includes features for data logging and reporting, allowing project managers to track progress and make informed decisions. The integration of software and hardware in 2D machine control systems is essential for achieving the high levels of accuracy and efficiency required in modern construction projects. The software must be compatible with a wide range of hardware components and be able to process large amounts of data in real-time. This requires sophisticated algorithms and advanced computing capabilities. Furthermore, the software must be regularly updated to incorporate new features and improvements, as well as to ensure compatibility with the latest hardware advancements. The combination of advanced hardware and sophisticated software in 2D machine control systems enables operators to perform tasks with greater precision and efficiency, ultimately leading to improved productivity and reduced operational costs.

Excavators, Dozers, Graders, Others in the Global 2D Engineering Vehicle Machine Control Market:

The usage of Global 2D Engineering Vehicle Machine Control Market technology is widespread across various types of construction and earthmoving equipment, including excavators, dozers, graders, and others. For excavators, 2D machine control systems provide operators with real-time information about the depth and slope of their digging, allowing them to achieve precise cuts and reduce the need for manual measurements. This not only improves the accuracy of the work but also increases the speed and efficiency of the excavation process. In the case of dozers, 2D machine control systems help operators maintain the correct blade position and angle, ensuring that the ground is leveled accurately and efficiently. This is particularly important for tasks such as grading and site preparation, where precision is crucial for the success of the project. For graders, 2D machine control systems provide real-time feedback on the position and angle of the blade, allowing operators to achieve precise grading and leveling. This is essential for tasks such as road construction and maintenance, where the quality of the finished surface is critical. In addition to excavators, dozers, and graders, 2D machine control systems are also used in other types of construction equipment, such as compactors and pavers. These systems help operators achieve precise compaction and paving, ensuring that the finished surface meets the required specifications. Overall, the use of 2D machine control systems in construction and earthmoving equipment leads to improved accuracy, efficiency, and productivity, ultimately resulting in cost savings and higher-quality work.

Global 2D Engineering Vehicle Machine Control Market Outlook:

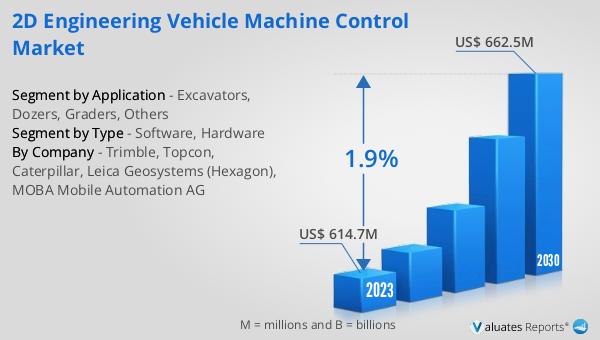

The global 2D Engineering Vehicle Machine Control market was valued at US$ 614.7 million in 2023 and is anticipated to reach US$ 662.5 million by 2030, witnessing a CAGR of 1.9% during the forecast period 2024-2030. This market outlook indicates a steady growth trajectory for the industry, driven by the increasing demand for advanced technology in construction and earthmoving operations. The adoption of 2D machine control systems is expected to continue to rise as construction companies seek to improve efficiency, accuracy, and productivity in their projects. The market's growth is also supported by the ongoing advancements in hardware and software technology, which are making 2D machine control systems more accessible and effective for a wider range of applications. As the industry continues to evolve, the integration of new features and improvements in both hardware and software components will further enhance the capabilities of 2D machine control systems, driving their adoption and contributing to the market's growth.

| Report Metric | Details |

| Report Name | 2D Engineering Vehicle Machine Control Market |

| Accounted market size in 2023 | US$ 614.7 million |

| Forecasted market size in 2030 | US$ 662.5 million |

| CAGR | 1.9% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Trimble, Topcon, Caterpillar, Leica Geosystems (Hexagon), MOBA Mobile Automation AG |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |