What is Global Copper Clad Laminate Market?

The Global Copper Clad Laminate (CCL) Market is a significant segment within the electronics industry. Copper Clad Laminate is a type of base material used in the manufacturing of printed circuit boards (PCBs), which are essential components in a wide range of electronic devices. CCL consists of a thin layer of copper foil bonded to a non-conductive substrate, typically made of materials like fiberglass or resin. This combination provides the necessary electrical conductivity and structural support for PCBs. The global market for CCL is driven by the increasing demand for electronic devices, advancements in technology, and the growing need for high-performance and reliable PCBs in various applications. The market encompasses a variety of CCL types, each designed to meet specific requirements in terms of thermal performance, mechanical strength, and environmental compliance. As the electronics industry continues to evolve, the demand for innovative and high-quality CCL products is expected to rise, making it a crucial area of focus for manufacturers and researchers alike.

Paper board, Composite Substrate, Normal FR4, High Tg FR-4, Halogen-free Board, Special Board, Others in the Global Copper Clad Laminate Market:

Paper board, Composite Substrate, Normal FR4, High Tg FR-4, Halogen-free Board, Special Board, and Others are various types of Copper Clad Laminates (CCLs) used in the global market, each serving distinct purposes based on their unique properties. Paper board CCLs are typically used in low-cost, low-performance applications where high thermal and mechanical properties are not critical. They are made from paper-based materials impregnated with resin and are suitable for simple electronic devices. Composite Substrate CCLs combine different materials to achieve a balance of performance characteristics, making them suitable for a wide range of applications. Normal FR4 is the most commonly used type of CCL, known for its good mechanical strength, electrical insulation, and moderate thermal performance. It is made from woven fiberglass cloth impregnated with epoxy resin and is widely used in consumer electronics, computers, and communication devices. High Tg FR-4 CCLs are similar to Normal FR4 but have a higher glass transition temperature (Tg), making them suitable for applications that require better thermal stability and reliability, such as automotive and industrial electronics. Halogen-free Boards are designed to meet environmental regulations by eliminating halogenated flame retardants, making them more environmentally friendly and suitable for applications where environmental compliance is critical. Special Boards are tailored for specific high-performance applications, such as high-frequency circuits, flexible circuits, and high-density interconnects (HDI). These boards often use advanced materials and manufacturing processes to achieve superior performance in terms of signal integrity, thermal management, and mechanical flexibility. Other types of CCLs include those designed for specific niche applications, such as military, aerospace, and medical devices, where unique performance characteristics are required. Each type of CCL plays a crucial role in the global market, catering to the diverse needs of various industries and driving innovation in electronic device manufacturing.

Computer, Communication, Consumer Electronics, Vehicle electronics, Industrial or Medical, Military or Space, Others in the Global Copper Clad Laminate Market:

The usage of Global Copper Clad Laminate (CCL) Market spans across several key areas, including computers, communication, consumer electronics, vehicle electronics, industrial or medical, military or space, and others. In the computer industry, CCLs are essential for manufacturing motherboards, graphic cards, and other critical components that require reliable electrical performance and mechanical stability. The demand for high-speed computing and advanced processing capabilities drives the need for high-quality CCLs that can support complex circuitry and high-density interconnects. In the communication sector, CCLs are used in the production of devices such as smartphones, routers, and base stations. These applications require CCLs with excellent signal integrity and thermal management to ensure reliable performance in high-frequency and high-power environments. Consumer electronics, including televisions, gaming consoles, and wearable devices, also rely heavily on CCLs for their PCBs. The trend towards miniaturization and multifunctionality in consumer electronics necessitates the use of advanced CCLs that can support compact and intricate designs. Vehicle electronics is another significant area where CCLs are used, particularly in the production of automotive control systems, infotainment systems, and advanced driver-assistance systems (ADAS). The automotive industry demands CCLs with high thermal stability, mechanical strength, and reliability to withstand harsh operating conditions. In the industrial and medical sectors, CCLs are used in various equipment and devices, such as industrial control systems, medical imaging devices, and diagnostic equipment. These applications require CCLs with high reliability, precision, and compliance with stringent safety standards. The military and space sectors also utilize CCLs for critical applications, including communication systems, navigation systems, and satellite technology. These applications demand CCLs with exceptional performance characteristics, such as high thermal resistance, mechanical durability, and resistance to harsh environmental conditions. Other areas where CCLs are used include renewable energy systems, such as solar panels and wind turbines, where they play a crucial role in the efficient conversion and management of electrical energy. Overall, the diverse applications of CCLs across various industries highlight their importance in the global market and the need for continuous innovation to meet the evolving demands of modern technology.

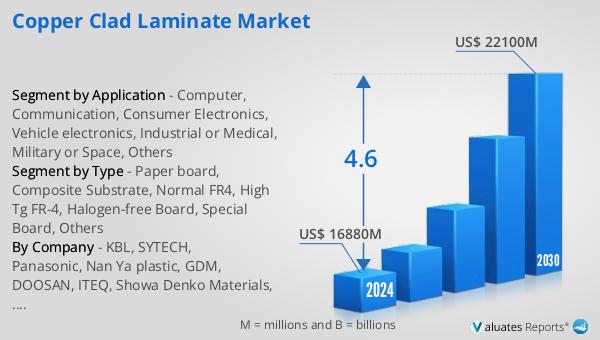

Global Copper Clad Laminate Market Outlook:

The global Copper Clad Laminate market is anticipated to expand from US$ 16,880 million in 2024 to US$ 22,100 million by 2030, reflecting a Compound Annual Growth Rate (CAGR) of 4.6% over the forecast period. The top five manufacturers globally hold a significant share, exceeding 45% of the market. Among the various product types, Normal FR4 stands out as the largest segment, accounting for nearly 33% of the market share. This growth trajectory underscores the increasing demand for high-quality CCLs driven by advancements in technology and the proliferation of electronic devices across various sectors. The dominance of Normal FR4 in the market highlights its widespread use and versatility in applications ranging from consumer electronics to industrial and automotive electronics. As the market continues to evolve, manufacturers are likely to focus on innovation and the development of specialized CCLs to cater to the specific needs of different industries. The projected growth of the global CCL market reflects the critical role these materials play in the electronics industry and the ongoing efforts to enhance their performance and environmental sustainability.

| Report Metric | Details |

| Report Name | Copper Clad Laminate Market |

| Accounted market size in 2024 | US$ 16880 in million |

| Forecasted market size in 2030 | US$ 22100 million |

| CAGR | 4.6 |

| Base Year | 2024 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Sales by Region |

|

| By Company | KBL, SYTECH, Panasonic, Nan Ya plastic, GDM, DOOSAN, ITEQ, Showa Denko Materials, EMC, Isola, Rogers, Shanghai Nanya, Mitsubishi, TUC, Wazam New Materials, JinBao, Chang Chun, GOWORLD, Sumitomo, Grace Electron, Ventec, Chaohua |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |