What is Global Carbide Grinding Wheels Market?

The Global Carbide Grinding Wheels Market is a specialized segment within the broader abrasives market, focusing on the production and distribution of grinding wheels made from carbide materials. These grinding wheels are essential tools in various industries due to their high hardness, wear resistance, and ability to maintain sharp cutting edges. Carbide grinding wheels are primarily used for precision grinding applications, where maintaining tight tolerances and achieving high surface finishes are critical. They are employed in processes such as cutting, grinding, and shaping hard materials like metals, stones, and ceramics. The market for these grinding wheels is driven by the increasing demand for high-performance tools in manufacturing, construction, and metalworking industries. Additionally, advancements in grinding wheel technology, such as the development of new bonding materials and manufacturing techniques, are contributing to the growth of this market. The global reach of the market is facilitated by the presence of numerous manufacturers and suppliers across different regions, ensuring the availability of these essential tools to a wide range of end-users.

Cylindrical Grinding, Internal Grinding, Surface Grinding, Centerless Grinding in the Global Carbide Grinding Wheels Market:

Cylindrical grinding, internal grinding, surface grinding, and centerless grinding are key processes within the Global Carbide Grinding Wheels Market, each serving distinct applications and industries. Cylindrical grinding involves the grinding of the external surface of cylindrical workpieces, which is essential in the production of precision components like shafts, bearings, and spindles. This process ensures that the workpieces achieve the desired dimensions and surface finish, making it crucial in industries such as automotive, aerospace, and machinery manufacturing. Internal grinding, on the other hand, focuses on the internal surfaces of cylindrical or conical workpieces. This process is vital for producing high-precision components like bushings, sleeves, and bearing races, which require tight tolerances and smooth finishes. Surface grinding is another critical process that involves the grinding of flat surfaces to achieve a high degree of flatness and surface finish. This process is widely used in the production of precision parts, molds, and dies, where achieving a smooth and accurate surface is essential. Centerless grinding, unlike the other processes, does not require the workpiece to be held between centers. Instead, it uses a rotating wheel to remove material from the workpiece, which is supported by a rest blade and a regulating wheel. This process is highly efficient for mass production of small cylindrical components, such as pins, rods, and tubes, making it popular in industries like automotive and electronics. The versatility and precision offered by these grinding processes, combined with the durability and performance of carbide grinding wheels, make them indispensable in various manufacturing and processing applications.

Metal Processing, Stone Processing, Steel Processing, Other in the Global Carbide Grinding Wheels Market:

The usage of Global Carbide Grinding Wheels Market extends across several key areas, including metal processing, stone processing, steel processing, and other specialized applications. In metal processing, carbide grinding wheels are essential for cutting, shaping, and finishing various metal components. Their high hardness and wear resistance make them ideal for grinding hard metals like stainless steel, titanium, and hardened alloys. These wheels are used in applications such as tool and die making, precision engineering, and metal fabrication, where achieving tight tolerances and high surface finishes are critical. In stone processing, carbide grinding wheels are employed for cutting, grinding, and polishing natural and engineered stones. Their ability to maintain sharp cutting edges and resist wear makes them suitable for processing hard materials like granite, marble, and quartz. These wheels are used in the production of countertops, tiles, and monuments, where precision and surface quality are essential. In steel processing, carbide grinding wheels play a crucial role in grinding and finishing steel components. They are used in applications such as roll grinding, surface grinding, and cylindrical grinding, where maintaining dimensional accuracy and surface integrity is vital. These wheels are also used in the production of steel tools, molds, and dies, where high performance and durability are required. Beyond these primary areas, carbide grinding wheels are also used in other specialized applications, such as the grinding of ceramics, composites, and glass. Their versatility and performance make them suitable for a wide range of industries, including aerospace, automotive, electronics, and construction. The ability of carbide grinding wheels to deliver consistent results and withstand demanding conditions makes them a preferred choice for various grinding and finishing operations.

Global Carbide Grinding Wheels Market Outlook:

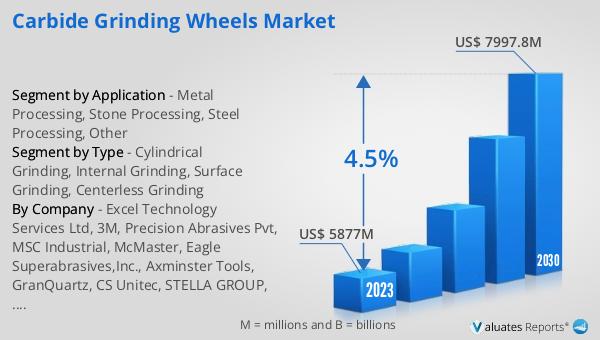

The global Carbide Grinding Wheels market was valued at US$ 5877 million in 2023 and is anticipated to reach US$ 7997.8 million by 2030, witnessing a CAGR of 4.5% during the forecast period 2024-2030. This market outlook indicates a steady growth trajectory driven by the increasing demand for high-performance grinding tools across various industries. The market's valuation in 2023 reflects the significant role that carbide grinding wheels play in precision grinding applications, where maintaining tight tolerances and achieving high surface finishes are critical. The projected growth to US$ 7997.8 million by 2030 underscores the expanding adoption of these grinding wheels in sectors such as manufacturing, construction, and metalworking. The compound annual growth rate (CAGR) of 4.5% during the forecast period highlights the sustained demand for durable and efficient grinding solutions. Factors contributing to this growth include advancements in grinding wheel technology, the rising need for precision-engineered components, and the increasing focus on improving production efficiency. As industries continue to seek high-quality grinding tools that can withstand demanding conditions and deliver consistent results, the global carbide grinding wheels market is poised for continued expansion.

| Report Metric | Details |

| Report Name | Carbide Grinding Wheels Market |

| Accounted market size in 2023 | US$ 5877 million |

| Forecasted market size in 2030 | US$ 7997.8 million |

| CAGR | 4.5% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Consumption by Region |

|

| By Company | Excel Technology Services Ltd, 3M, Precision Abrasives Pvt, MSC Industrial, McMaster, Eagle Superabrasives,Inc., Axminster Tools, GranQuartz, CS Unitec, STELLA GROUP, Titan Tool Supply, Strauss&Co, Moore Tool, Hauser Incorporated, Diagrind, Niabraze |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |