What is Global Automotive Water Pump Market?

The Global Automotive Water Pump Market is a crucial segment within the automotive industry, focusing on the production and distribution of water pumps used in vehicles. These water pumps are essential components that help regulate the engine's temperature by circulating coolant through the engine block, hoses, and radiator. This process prevents the engine from overheating, ensuring optimal performance and longevity. The market encompasses a wide range of water pumps designed for various types of vehicles, including passenger cars and commercial vehicles. With the increasing demand for efficient and reliable automotive components, the global automotive water pump market is experiencing steady growth. Technological advancements and the rising adoption of electric vehicles are also contributing to the market's expansion. As the automotive industry continues to evolve, the importance of high-quality water pumps in maintaining vehicle performance and safety remains paramount.

Mechanical Water Pump, Electric Water Pump in the Global Automotive Water Pump Market:

Mechanical water pumps and electric water pumps are two primary types of water pumps used in the global automotive water pump market. Mechanical water pumps are traditionally driven by the engine's crankshaft through a belt and pulley system. They have been the standard in the automotive industry for many years due to their simplicity and reliability. These pumps operate by using the engine's power to drive an impeller, which circulates coolant through the engine and radiator. Mechanical water pumps are known for their durability and cost-effectiveness, making them a popular choice for a wide range of vehicles. However, they are not without their drawbacks. Since they are directly connected to the engine, their performance is tied to the engine's speed, which can lead to inefficiencies at lower speeds or during idling. Additionally, mechanical water pumps can contribute to parasitic drag, reducing overall engine efficiency. On the other hand, electric water pumps represent a more modern approach to engine cooling. These pumps are powered by the vehicle's electrical system rather than the engine itself. This allows for more precise control over the coolant flow, independent of the engine's speed. Electric water pumps can be programmed to operate only when needed, reducing energy consumption and improving fuel efficiency. They are particularly beneficial in hybrid and electric vehicles, where minimizing mechanical load on the engine is crucial for maximizing battery life and overall efficiency. Electric water pumps also offer the advantage of being able to continue operating after the engine is turned off, providing additional cooling during hot weather or after a long drive. This can help prevent heat soak and extend the life of engine components. Despite their advantages, electric water pumps are generally more expensive than their mechanical counterparts. They require sophisticated electronic control systems and robust electrical components to ensure reliable operation. Additionally, the integration of electric water pumps into existing vehicle designs can be challenging, requiring significant modifications to the cooling system and electrical architecture. Nevertheless, the benefits of improved efficiency, reduced emissions, and enhanced engine performance make electric water pumps an attractive option for modern vehicles. In summary, the global automotive water pump market is characterized by the coexistence of mechanical and electric water pumps, each with its own set of advantages and challenges. Mechanical water pumps continue to be widely used due to their simplicity, reliability, and cost-effectiveness. However, the growing emphasis on fuel efficiency, emissions reduction, and advanced vehicle technologies is driving the adoption of electric water pumps. As the automotive industry continues to evolve, the balance between these two types of water pumps will likely shift, with electric water pumps playing an increasingly important role in the future of vehicle cooling systems.

Passenger Car, Commercial Vehicle in the Global Automotive Water Pump Market:

The usage of automotive water pumps in passenger cars and commercial vehicles highlights their critical role in ensuring engine performance and longevity. In passenger cars, water pumps are essential for maintaining the engine's optimal operating temperature. These vehicles are designed for comfort, efficiency, and performance, and a reliable cooling system is crucial to achieving these goals. Water pumps in passenger cars help prevent overheating, which can lead to engine damage and reduced performance. They ensure that the coolant circulates effectively, dissipating heat and maintaining a stable temperature. This is particularly important in modern passenger cars, which often feature smaller, high-performance engines that generate significant heat. The use of electric water pumps in passenger cars is becoming more common, especially in hybrid and electric vehicles. These pumps offer precise control over coolant flow, improving efficiency and reducing emissions. They also provide additional cooling after the engine is turned off, protecting sensitive components and enhancing overall vehicle reliability. In commercial vehicles, the role of water pumps is equally important, if not more so. These vehicles, which include trucks, buses, and other heavy-duty applications, often operate under demanding conditions and carry heavy loads. The engines in commercial vehicles are typically larger and generate more heat, making effective cooling essential. Mechanical water pumps have traditionally been the standard in commercial vehicles due to their robustness and ability to handle high coolant flow rates. However, the adoption of electric water pumps is also gaining traction in this segment. Electric water pumps offer several advantages for commercial vehicles, including improved fuel efficiency and reduced emissions. They can be programmed to operate based on the vehicle's specific cooling needs, optimizing performance and reducing energy consumption. This is particularly beneficial for long-haul trucks and buses, where fuel efficiency and reliability are critical factors. The integration of water pumps in both passenger cars and commercial vehicles also involves considerations related to maintenance and durability. Water pumps must be designed to withstand the rigors of daily use, including exposure to high temperatures, pressure, and various contaminants. Regular maintenance is essential to ensure the longevity and performance of water pumps. This includes checking for leaks, inspecting the drive belt (in the case of mechanical pumps), and ensuring that the coolant is clean and at the proper level. Advances in materials and manufacturing processes have led to the development of more durable and efficient water pumps, further enhancing their reliability and performance. In conclusion, the usage of automotive water pumps in passenger cars and commercial vehicles underscores their vital role in engine cooling and overall vehicle performance. While mechanical water pumps continue to be widely used due to their simplicity and reliability, the shift towards electric water pumps is evident, driven by the need for improved efficiency and reduced emissions. As the automotive industry continues to innovate, the importance of high-quality water pumps in maintaining vehicle performance and safety remains paramount.

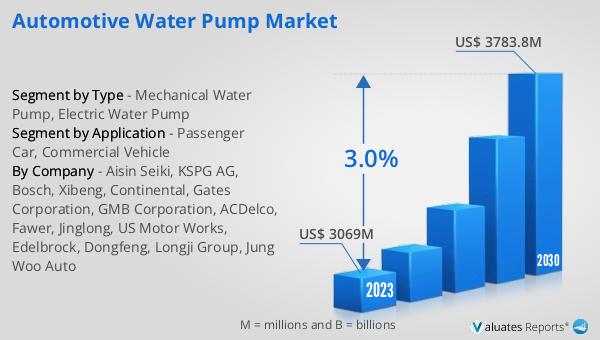

Global Automotive Water Pump Market Outlook:

The global automotive water pump market is anticipated to expand from $3,168.9 million in 2024 to $3,783.8 million by 2030, reflecting a compound annual growth rate (CAGR) of 3.0% over the forecast period. The top four global manufacturers collectively hold approximately 35% of the market share. Among the various product types, mechanical water pumps dominate the market, accounting for over 85% of the total share.

| Report Metric | Details |

| Report Name | Automotive Water Pump Market |

| Accounted market size in 2024 | US$ 3168.9 million |

| Forecasted market size in 2030 | US$ 3783.8 million |

| CAGR | 3.0 |

| Base Year | 2024 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Sales by Region |

|

| By Company | Aisin Seiki, KSPG AG, Bosch, Xibeng, Continental, Gates Corporation, GMB Corporation, ACDelco, Fawer, Jinglong, US Motor Works, Edelbrock, Dongfeng, Longji Group, Jung Woo Auto |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |