What is Global Biomass Carbonization Furnace Market?

The Global Biomass Carbonization Furnace Market refers to the industry focused on the production and sale of furnaces designed to convert biomass into charcoal through a process called carbonization. Biomass, which includes organic materials like wood, agricultural residues, and other plant-based materials, is subjected to high temperatures in the absence of oxygen in these furnaces. This process not only produces charcoal but also generates by-products such as bio-oil and syngas, which can be used for energy production. The market for these furnaces is driven by the increasing demand for renewable energy sources, the need for sustainable waste management solutions, and the growing awareness of the environmental benefits of using biomass over fossil fuels. As industries and governments worldwide seek to reduce carbon footprints and promote green energy, the adoption of biomass carbonization furnaces is expected to rise. These furnaces are utilized in various sectors, including industrial, agricultural, and residential applications, making them a versatile solution for energy and waste management needs.

Batch Type Biomass Carbonization Furnace, Continuous Type Biomass Carbonization Furnace in the Global Biomass Carbonization Furnace Market:

Batch Type Biomass Carbonization Furnaces and Continuous Type Biomass Carbonization Furnaces are two primary categories within the Global Biomass Carbonization Furnace Market. Batch Type Biomass Carbonization Furnaces operate by processing a set amount of biomass in a single cycle. Once the biomass is loaded into the furnace, it undergoes carbonization, and the process is completed before a new batch is introduced. This type of furnace is typically simpler in design and operation, making it suitable for smaller-scale applications or for use in areas where the biomass supply is inconsistent. Batch furnaces are often favored for their ability to handle a variety of biomass types and their relatively lower initial investment costs. On the other hand, Continuous Type Biomass Carbonization Furnaces are designed for ongoing, uninterrupted processing of biomass. These furnaces allow for the continuous feeding of biomass and the simultaneous removal of the resulting charcoal and by-products. This type of furnace is more complex and requires a higher initial investment but offers greater efficiency and higher throughput. Continuous furnaces are ideal for large-scale industrial applications where a steady supply of biomass is available, and there is a need for consistent production. The choice between batch and continuous furnaces depends on factors such as the scale of operation, the type of biomass being processed, and the specific requirements of the end-user. Both types of furnaces play a crucial role in the Global Biomass Carbonization Furnace Market, catering to different needs and applications.

Industrial, Agriculturial, Others in the Global Biomass Carbonization Furnace Market:

The usage of Global Biomass Carbonization Furnace Market spans across various sectors, including industrial, agricultural, and others. In the industrial sector, these furnaces are primarily used for the production of charcoal, which serves as a key ingredient in various manufacturing processes. Charcoal produced through biomass carbonization is used in the production of activated carbon, which is essential for water purification, air filtration, and other applications. Additionally, the by-products of the carbonization process, such as bio-oil and syngas, can be utilized as alternative energy sources, reducing the reliance on fossil fuels and contributing to a more sustainable energy mix. In the agricultural sector, biomass carbonization furnaces are employed to convert agricultural residues, such as crop stalks, husks, and other plant materials, into biochar. Biochar is a valuable soil amendment that enhances soil fertility, improves water retention, and reduces greenhouse gas emissions from agricultural activities. By converting agricultural waste into biochar, farmers can improve crop yields and promote sustainable farming practices. Beyond industrial and agricultural applications, biomass carbonization furnaces are also used in other areas, such as residential heating and cooking. In regions where traditional biomass fuels like wood and charcoal are commonly used for cooking and heating, these furnaces offer a more efficient and environmentally friendly alternative. By producing high-quality charcoal and biochar, these furnaces help reduce indoor air pollution and deforestation, contributing to better health outcomes and environmental conservation. Overall, the versatility and environmental benefits of biomass carbonization furnaces make them a valuable tool in various sectors, supporting sustainable development and the transition to a greener economy.

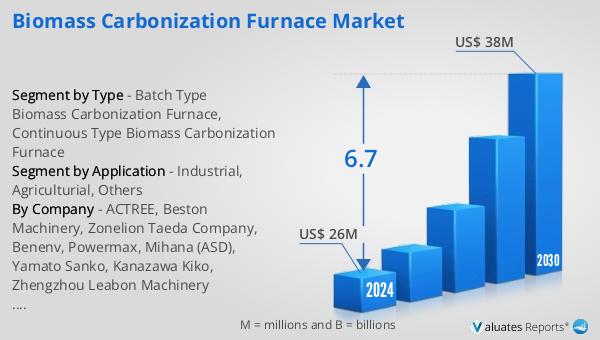

Global Biomass Carbonization Furnace Market Outlook:

The global Biomass Carbonization Furnace market is anticipated to grow significantly, reaching an estimated value of US$ 38 million by 2030, up from US$ 26 million in 2024, reflecting a compound annual growth rate (CAGR) of 6.7% between 2024 and 2030. The market is characterized by a competitive landscape, with the top five players collectively holding over 23% of the market share. Geographically, the Asia-Pacific region dominates the market, accounting for approximately 43% of the total share. This is followed by North America and Europe, which hold shares of 30% and 20%, respectively. The growth in these regions is driven by increasing demand for renewable energy sources, government initiatives promoting sustainable practices, and the rising awareness of the environmental benefits of biomass carbonization. As industries and consumers alike seek to reduce their carbon footprints and adopt greener technologies, the market for biomass carbonization furnaces is expected to expand, offering numerous opportunities for innovation and development.

| Report Metric | Details |

| Report Name | Biomass Carbonization Furnace Market |

| Accounted market size in 2024 | an estimated US$ 26 million |

| Forecasted market size in 2030 | US$ 38 million |

| CAGR | 6.7% |

| Base Year | 2024 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | ACTREE, Beston Machinery, Zonelion Taeda Company, Benenv, Powermax, Mihana (ASD), Yamato Sanko, Kanazawa Kiko, Zhengzhou Leabon Machinery Equipment, Kingtiger Environmental Technology, S K KOGYO Y.K., EP Machinery, ZE Energy, ECOKS |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |