What is Global Metallocene Polyethylene Market?

The Global Metallocene Polyethylene Market refers to the worldwide industry focused on the production and distribution of metallocene polyethylene (mPE). This type of polyethylene is created using metallocene catalysts, which allow for more precise control over the polymer structure, resulting in enhanced material properties. mPE is known for its superior strength, flexibility, and clarity compared to traditional polyethylene. These attributes make it highly desirable for various applications, including packaging, films, and industrial uses. The market is driven by the increasing demand for high-performance plastics in various sectors, such as food packaging, agriculture, and construction. Additionally, advancements in polymer technology and the growing emphasis on sustainable and recyclable materials are contributing to the market's expansion. The global reach of the market means that it is influenced by regional economic conditions, regulatory environments, and technological advancements, making it a dynamic and evolving industry.

Film Grade, Rotomolding Grade, Pipe Grade, Others in the Global Metallocene Polyethylene Market:

Film Grade, Rotomolding Grade, Pipe Grade, and Others are different classifications within the Global Metallocene Polyethylene Market, each serving distinct applications and industries. Film Grade mPE is primarily used in the production of high-quality films due to its excellent clarity, strength, and flexibility. These films are widely used in packaging, including food packaging, where they help in preserving the freshness and extending the shelf life of products. The superior mechanical properties of Film Grade mPE also make it suitable for stretch and shrink films, which are used in bundling and securing goods during transportation. Rotomolding Grade mPE is designed for rotational molding processes, which involve creating hollow plastic products by heating and rotating molds. This grade of mPE offers exceptional impact resistance and durability, making it ideal for manufacturing large, complex-shaped items such as tanks, containers, and playground equipment. The uniformity and consistency of Rotomolding Grade mPE ensure that the final products have smooth surfaces and high structural integrity. Pipe Grade mPE is engineered for use in the production of pipes and tubing, where it provides excellent resistance to environmental stress cracking, chemical corrosion, and abrasion. These properties make it suitable for applications in water supply, gas distribution, and industrial piping systems. The flexibility and toughness of Pipe Grade mPE also allow for easy installation and long-term reliability in various environmental conditions. The "Others" category encompasses a range of specialized mPE grades tailored for specific applications. This includes injection molding grades used in producing high-precision components, extrusion grades for creating profiles and sheets, and blow molding grades for manufacturing bottles and containers. Each of these grades is formulated to meet the unique requirements of their respective applications, offering a balance of mechanical properties, processability, and performance. The versatility of metallocene polyethylene across these different grades highlights its importance in modern manufacturing and its ability to meet the diverse needs of various industries.

Food Packaging, Non-food Packaging, Agricultural Film, Industrial, Others in the Global Metallocene Polyethylene Market:

The usage of Global Metallocene Polyethylene Market spans several key areas, including Food Packaging, Non-food Packaging, Agricultural Film, Industrial, and Others. In Food Packaging, mPE is highly valued for its ability to create films with excellent clarity, strength, and barrier properties. These films help in preserving the freshness and extending the shelf life of food products by protecting them from moisture, oxygen, and contaminants. The flexibility and sealability of mPE films also make them ideal for creating pouches, bags, and wraps that can withstand the rigors of transportation and storage. In Non-food Packaging, mPE is used to produce films and wraps for a variety of consumer goods, including personal care products, electronics, and household items. The superior mechanical properties of mPE ensure that these packaging materials provide adequate protection and durability, reducing the risk of damage during handling and shipping. Agricultural Film is another significant application of mPE, where it is used to create mulch films, greenhouse covers, and silage wraps. These films help in enhancing crop yield and quality by regulating soil temperature, retaining moisture, and protecting plants from pests and harsh weather conditions. The UV resistance and durability of mPE films make them suitable for prolonged outdoor use, ensuring that they can withstand the environmental stresses encountered in agricultural settings. In the Industrial sector, mPE is used in the production of various components and materials that require high strength, flexibility, and chemical resistance. This includes industrial films, liners, and geomembranes used in construction, mining, and waste management applications. The robustness and reliability of mPE materials make them ideal for demanding industrial environments where performance and longevity are critical. The "Others" category encompasses a wide range of specialized applications, including medical packaging, automotive components, and consumer goods. In medical packaging, mPE is used to create sterile barrier systems and flexible packaging solutions that ensure the safety and integrity of medical devices and pharmaceuticals. In the automotive industry, mPE is used to produce lightweight and durable components that contribute to fuel efficiency and vehicle performance. The versatility and adaptability of metallocene polyethylene make it a valuable material across these diverse applications, driving its demand and growth in the global market.

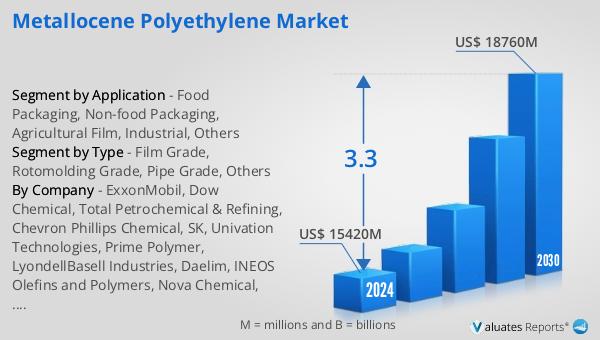

Global Metallocene Polyethylene Market Outlook:

The global Metallocene Polyethylene market is anticipated to expand from US$ 15,420 million in 2024 to US$ 18,760 million by 2030, reflecting a Compound Annual Growth Rate (CAGR) of 3.3% during the forecast period. Leading companies in the Metallocene Polyethylene industry include ExxonMobil, Dow Chemical, Mitsui Chemicals, Chevron Phillips Chemical, INEOS, and LyondellBasell, which collectively hold approximately 57% of the market share. North America stands out as the primary region for this market, accounting for about 33% of the global share.

| Report Metric | Details |

| Report Name | Metallocene Polyethylene Market |

| Accounted market size in 2024 | US$ 15420 in million |

| Forecasted market size in 2030 | US$ 18760 million |

| CAGR | 3.3 |

| Base Year | 2024 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Sales by Region |

|

| By Company | ExxonMobil, Dow Chemical, Total Petrochemical & Refining, Chevron Phillips Chemical, SK, Univation Technologies, Prime Polymer, LyondellBasell Industries, Daelim, INEOS Olefins and Polymers, Nova Chemical, Borealis, UBE, Qilu Petrochemical, PTT Global, CNPC |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |