What is Global Aluminium Wheels Market?

The global aluminium wheels market is a significant segment within the automotive industry, focusing on the production and distribution of wheels made from aluminium. Aluminium wheels are preferred over traditional steel wheels due to their lighter weight, which contributes to improved fuel efficiency and better vehicle performance. These wheels are also known for their aesthetic appeal, corrosion resistance, and ability to dissipate heat more effectively, which enhances braking performance. The market encompasses a wide range of products, including wheels for passenger vehicles, commercial vehicles, and specialty vehicles. The demand for aluminium wheels is driven by factors such as the increasing production of vehicles, rising consumer preference for high-performance and aesthetically pleasing wheels, and stringent regulations aimed at reducing vehicle emissions. The market is characterized by the presence of several key players who are continuously innovating to offer advanced and cost-effective solutions. Additionally, the market is influenced by trends such as the growing popularity of electric vehicles and the increasing focus on lightweight materials in automotive manufacturing. Overall, the global aluminium wheels market plays a crucial role in the automotive sector, contributing to the development of more efficient and environmentally friendly vehicles.

Casting, Forging in the Global Aluminium Wheels Market:

Casting and forging are two primary manufacturing processes used in the production of aluminium wheels, each with its own set of advantages and applications. Casting involves pouring molten aluminium into a mold to create the desired wheel shape. This process is relatively cost-effective and allows for the production of complex designs and intricate details. There are different types of casting methods, including gravity casting, low-pressure casting, and high-pressure die casting. Gravity casting is the simplest form, where molten aluminium is poured into a mold and allowed to solidify under the force of gravity. Low-pressure casting involves applying a slight pressure to the molten aluminium to fill the mold, resulting in a denser and stronger wheel. High-pressure die casting uses significant pressure to force the molten aluminium into the mold, producing wheels with excellent surface finish and dimensional accuracy. On the other hand, forging involves shaping aluminium by applying compressive forces using a hammer or press. This process results in wheels that are stronger and more durable compared to cast wheels. Forged wheels are typically lighter and have better mechanical properties, making them ideal for high-performance and luxury vehicles. The forging process can be further divided into open-die forging and closed-die forging. Open-die forging involves shaping the aluminium between flat or simple-shaped dies, while closed-die forging uses more complex dies to produce precise shapes. Both casting and forging have their own set of challenges and benefits. Casting is generally more cost-effective and suitable for mass production, but the wheels may not be as strong as forged ones. Forging, while more expensive, produces wheels with superior strength and performance characteristics. The choice between casting and forging depends on various factors, including the intended application, performance requirements, and budget constraints. In the global aluminium wheels market, both casting and forging play vital roles in meeting the diverse needs of automotive manufacturers and consumers. As technology advances, manufacturers are continually exploring new methods and materials to enhance the performance, durability, and aesthetics of aluminium wheels. This ongoing innovation ensures that the market remains dynamic and responsive to the evolving demands of the automotive industry.

Passenger Vehicle, Commercial Vehicle in the Global Aluminium Wheels Market:

The usage of aluminium wheels in passenger vehicles and commercial vehicles highlights their versatility and importance in the automotive sector. In passenger vehicles, aluminium wheels are highly valued for their lightweight properties, which contribute to improved fuel efficiency and better handling. The reduced weight of aluminium wheels lowers the overall unsprung mass of the vehicle, leading to enhanced ride quality and reduced wear on suspension components. Additionally, aluminium wheels offer superior heat dissipation, which is crucial for maintaining optimal braking performance, especially during high-speed driving or in demanding conditions. The aesthetic appeal of aluminium wheels also plays a significant role in their popularity among passenger vehicle owners. These wheels can be designed in various styles and finishes, allowing car manufacturers and consumers to customize the appearance of their vehicles. In commercial vehicles, aluminium wheels are equally important, though the focus is often on durability and load-bearing capacity. Commercial vehicles, such as trucks and buses, require wheels that can withstand heavy loads and harsh operating conditions. Aluminium wheels, with their excellent strength-to-weight ratio, provide a reliable solution for these demanding applications. The reduced weight of aluminium wheels also contributes to better fuel efficiency in commercial vehicles, which is a critical factor for fleet operators looking to minimize operating costs. Furthermore, the corrosion resistance of aluminium wheels ensures a longer lifespan, reducing the need for frequent replacements and maintenance. This durability is particularly beneficial for commercial vehicles that operate in challenging environments, such as construction sites or areas with harsh weather conditions. Overall, the use of aluminium wheels in both passenger and commercial vehicles underscores their importance in enhancing vehicle performance, efficiency, and aesthetics. As the automotive industry continues to evolve, the demand for high-quality aluminium wheels is expected to remain strong, driven by the need for lightweight, durable, and visually appealing wheel solutions.

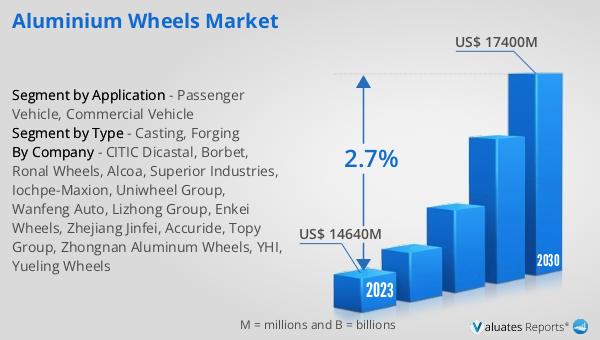

Global Aluminium Wheels Market Outlook:

The global aluminium wheels market was valued at approximately $14.64 billion in 2023 and is projected to reach around $17.4 billion by 2030, reflecting a compound annual growth rate (CAGR) of 2.7% during the forecast period from 2024 to 2030. This growth is indicative of the increasing demand for aluminium wheels across various segments of the automotive industry. The market's expansion can be attributed to several factors, including the rising production of vehicles, growing consumer preference for high-performance and aesthetically pleasing wheels, and stringent regulations aimed at reducing vehicle emissions. Aluminium wheels are favored for their lightweight properties, which contribute to improved fuel efficiency and better vehicle performance. Additionally, their superior heat dissipation capabilities enhance braking performance, making them a preferred choice for both passenger and commercial vehicles. The market is characterized by continuous innovation, with manufacturers exploring new methods and materials to enhance the performance, durability, and aesthetics of aluminium wheels. As the automotive industry continues to evolve, the global aluminium wheels market is expected to remain dynamic and responsive to the changing demands of consumers and regulatory bodies. This ongoing growth and innovation ensure that aluminium wheels will continue to play a crucial role in the development of more efficient and environmentally friendly vehicles.

| Report Metric | Details |

| Report Name | Aluminium Wheels Market |

| Accounted market size in 2023 | US$ 14640 million |

| Forecasted market size in 2030 | US$ 17400 million |

| CAGR | 2.7% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | CITIC Dicastal, Borbet, Ronal Wheels, Alcoa, Superior Industries, Iochpe-Maxion, Uniwheel Group, Wanfeng Auto, Lizhong Group, Enkei Wheels, Zhejiang Jinfei, Accuride, Topy Group, Zhongnan Aluminum Wheels, YHI, Yueling Wheels |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |