What is Global Wire Bonding Machine Market?

The Global Wire Bonding Machine Market refers to the industry focused on the production and sale of machines used for wire bonding, a crucial process in semiconductor and electronics manufacturing. Wire bonding machines are essential for connecting semiconductor devices to their packages using fine wires, typically made of gold, aluminum, or copper. These machines are used to create electrical interconnections between the silicon chip and the external leads of the semiconductor device. The market for these machines is driven by the increasing demand for electronic devices, advancements in semiconductor technology, and the need for high-precision and reliable bonding solutions. The global wire bonding machine market encompasses various types of machines, including fully automatic, semi-automatic, and manual models, catering to different levels of production requirements and technological sophistication. The market is characterized by continuous innovation, with manufacturers striving to improve the speed, accuracy, and efficiency of their machines to meet the evolving needs of the semiconductor and electronics industries.

Fully Automatic, Semi-automatic in the Global Wire Bonding Machine Market:

Fully automatic wire bonding machines are designed to perform the wire bonding process with minimal human intervention, offering high precision, speed, and consistency. These machines are equipped with advanced features such as automated wire feeding, bonding, and cutting, as well as sophisticated control systems that ensure optimal performance. Fully automatic wire bonding machines are ideal for high-volume production environments where efficiency and accuracy are paramount. They are commonly used in the semiconductor industry for the mass production of integrated circuits (ICs), microelectromechanical systems (MEMS), and other electronic components. The automation of the wire bonding process reduces the risk of human error, enhances production throughput, and ensures consistent quality, making these machines a preferred choice for large-scale manufacturers. On the other hand, semi-automatic wire bonding machines require some level of human intervention during the bonding process. These machines typically involve manual loading and unloading of components, as well as manual alignment and positioning of the wire. However, the actual bonding process is automated, ensuring precision and consistency in the wire bonds. Semi-automatic wire bonding machines are suitable for medium to low-volume production environments where flexibility and cost-effectiveness are important. They offer a balance between automation and manual control, allowing operators to make adjustments and fine-tune the bonding process as needed. These machines are often used in research and development (R&D) settings, prototyping, and small-scale production runs. Both fully automatic and semi-automatic wire bonding machines play a crucial role in the global wire bonding machine market, catering to different segments of the industry based on production volume, complexity, and budget constraints. Fully automatic machines are favored by large manufacturers with high production demands, while semi-automatic machines are preferred by smaller companies, R&D labs, and niche manufacturers who require flexibility and customization. The choice between fully automatic and semi-automatic wire bonding machines depends on various factors, including the specific application, production requirements, and available resources. As the demand for electronic devices continues to grow, the global wire bonding machine market is expected to see increased adoption of both types of machines, driven by the need for efficient, reliable, and cost-effective bonding solutions.

Semiconductor Industry, Electronics Manufacturing, Others in the Global Wire Bonding Machine Market:

The global wire bonding machine market finds extensive usage in various industries, with the semiconductor industry being one of the primary sectors. In the semiconductor industry, wire bonding machines are used to create electrical connections between the silicon chip and the external leads of the semiconductor device. This process is critical for the functionality and performance of integrated circuits (ICs), microelectromechanical systems (MEMS), and other semiconductor components. The precision and reliability of wire bonding machines are essential for ensuring the performance and longevity of semiconductor devices. As the demand for advanced semiconductor technologies continues to grow, the need for high-quality wire bonding machines in this industry is expected to increase. In the electronics manufacturing sector, wire bonding machines are used to assemble a wide range of electronic devices, including smartphones, tablets, laptops, and other consumer electronics. The miniaturization of electronic components and the increasing complexity of electronic devices have made wire bonding an essential process in electronics manufacturing. Wire bonding machines enable manufacturers to create reliable and high-performance connections between different components, ensuring the overall functionality and durability of electronic devices. The use of wire bonding machines in electronics manufacturing helps improve production efficiency, reduce costs, and enhance product quality, making them a vital tool for manufacturers in this industry. Apart from the semiconductor and electronics manufacturing industries, wire bonding machines are also used in other sectors such as automotive, aerospace, and medical devices. In the automotive industry, wire bonding machines are used to assemble electronic control units (ECUs), sensors, and other electronic components that are critical for the performance and safety of modern vehicles. In the aerospace industry, wire bonding machines are used to manufacture avionics systems, communication devices, and other electronic components that require high reliability and precision. In the medical devices industry, wire bonding machines are used to assemble various medical electronics, including diagnostic equipment, monitoring devices, and implantable devices. The use of wire bonding machines in these industries helps ensure the performance, reliability, and safety of critical electronic components and systems. Overall, the global wire bonding machine market plays a crucial role in various industries, enabling the production of high-quality and reliable electronic components and devices. The increasing demand for advanced technologies, miniaturization of electronic components, and the need for high-precision and efficient manufacturing processes are driving the adoption of wire bonding machines across different sectors. As industries continue to evolve and innovate, the importance of wire bonding machines in ensuring the performance and reliability of electronic devices is expected to grow, further fueling the demand for these machines in the global market.

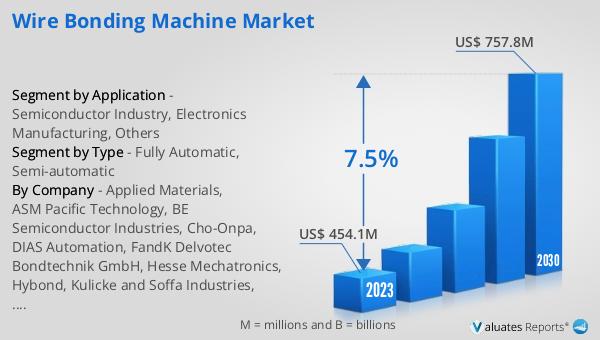

Global Wire Bonding Machine Market Outlook:

The global wire bonding machine market was valued at US$ 454.1 million in 2023 and is projected to reach US$ 757.8 million by 2030, reflecting a compound annual growth rate (CAGR) of 7.5% during the forecast period from 2024 to 2030. This significant growth is driven by the increasing demand for electronic devices, advancements in semiconductor technology, and the need for high-precision and reliable bonding solutions. As the market continues to expand, manufacturers are focusing on developing innovative and efficient wire bonding machines to meet the evolving needs of the semiconductor and electronics industries. The projected growth in the market underscores the importance of wire bonding machines in the production of high-quality and reliable electronic components and devices.

| Report Metric | Details |

| Report Name | Wire Bonding Machine Market |

| Accounted market size in 2023 | US$ 454.1 million |

| Forecasted market size in 2030 | US$ 757.8 million |

| CAGR | 7.5% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Applied Materials, ASM Pacific Technology, BE Semiconductor Industries, Cho-Onpa, DIAS Automation, FandK Delvotec Bondtechnik GmbH, Hesse Mechatronics, Hybond, Kulicke and Soffa Industries, Palomar Technologies, Shinkawa Electric, TPT, West Bond |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |