What is Global Wind Turbine Main Shaft Market?

The Global Wind Turbine Main Shaft Market refers to the industry focused on the production, distribution, and maintenance of main shafts used in wind turbines. These main shafts are critical components that connect the turbine's rotor to the generator, enabling the conversion of wind energy into electrical power. The market encompasses various activities, including the manufacturing of main shafts, the supply chain logistics involved in delivering these components to wind turbine manufacturers, and the after-sales services required to maintain and repair them. The demand for wind turbine main shafts is driven by the increasing adoption of wind energy as a sustainable and renewable energy source. As countries and companies strive to reduce their carbon footprints and transition to cleaner energy solutions, the need for efficient and reliable wind turbine components, such as main shafts, continues to grow. This market is characterized by technological advancements aimed at improving the durability and performance of main shafts, as well as efforts to reduce production costs and enhance supply chain efficiency.

Horizontal Shaft, Vertical Shaft in the Global Wind Turbine Main Shaft Market:

In the Global Wind Turbine Main Shaft Market, there are two primary types of shafts: horizontal and vertical. Horizontal shafts are the most common and are typically used in horizontal-axis wind turbines (HAWTs). These turbines have blades that rotate around a horizontal axis, similar to a traditional windmill. The main shaft in a HAWT is designed to withstand significant mechanical stress and torque as it transfers the rotational energy from the blades to the generator. Horizontal shafts are favored for their efficiency and ability to capture wind from different directions, making them suitable for a wide range of wind conditions. On the other hand, vertical shafts are used in vertical-axis wind turbines (VAWTs). These turbines have blades that rotate around a vertical axis, and the main shaft is oriented vertically. VAWTs are less common than HAWTs but offer certain advantages, such as the ability to operate in turbulent wind conditions and the potential for easier maintenance since the generator and other components can be located closer to the ground. Vertical shafts in VAWTs must be designed to handle different types of mechanical loads compared to horizontal shafts, as the forces acting on the blades and shaft are distributed differently. Both horizontal and vertical shafts play crucial roles in the overall performance and reliability of wind turbines. The choice between horizontal and vertical shafts depends on various factors, including the specific application, wind conditions, and design preferences of the wind turbine manufacturer. In recent years, there has been a growing interest in developing advanced materials and manufacturing techniques to enhance the strength and durability of both horizontal and vertical shafts. This includes the use of high-strength steel alloys, composite materials, and precision engineering processes to ensure that the shafts can withstand the demanding operational conditions of wind turbines. Additionally, the integration of smart technologies, such as sensors and monitoring systems, is becoming more prevalent in the design of wind turbine main shafts. These technologies enable real-time monitoring of the shaft's performance, allowing for predictive maintenance and reducing the risk of unexpected failures. As the wind energy industry continues to evolve, the Global Wind Turbine Main Shaft Market is expected to see ongoing innovation and development in both horizontal and vertical shaft designs. This will be driven by the need for more efficient, reliable, and cost-effective wind turbine components to support the growing demand for renewable energy worldwide.

Offshore, Land in the Global Wind Turbine Main Shaft Market:

The usage of Global Wind Turbine Main Shaft Market components varies significantly between offshore and land-based wind turbines. Offshore wind turbines are installed in bodies of water, typically on the continental shelf, where wind speeds are generally higher and more consistent than on land. The main shafts used in offshore wind turbines must be designed to withstand harsh marine environments, including exposure to saltwater, high humidity, and strong winds. These shafts are often made from corrosion-resistant materials and undergo rigorous testing to ensure their durability and reliability. Offshore wind farms can generate large amounts of electricity due to the higher wind speeds, but they also face unique challenges, such as the difficulty of installation and maintenance in remote and often harsh conditions. The main shafts in offshore turbines must be robust enough to handle these challenges while maintaining optimal performance. On the other hand, land-based wind turbines are installed onshore, in locations such as open fields, hills, and mountains. The main shafts used in these turbines must be designed to handle a wide range of wind conditions, from gentle breezes to strong gusts. Land-based wind turbines are generally easier to install and maintain compared to their offshore counterparts, but they still require high-quality main shafts to ensure efficient and reliable operation. The materials and manufacturing processes used for land-based turbine shafts are similar to those used for offshore turbines, with a focus on strength, durability, and cost-effectiveness. Both offshore and land-based wind turbines benefit from advancements in main shaft technology, such as the use of high-strength steel alloys, composite materials, and precision engineering techniques. These innovations help improve the performance and longevity of the main shafts, reducing the need for frequent maintenance and minimizing downtime. Additionally, the integration of smart technologies, such as sensors and monitoring systems, allows for real-time performance tracking and predictive maintenance, further enhancing the reliability of wind turbine main shafts. As the demand for renewable energy continues to grow, the Global Wind Turbine Main Shaft Market will play a crucial role in supporting the development and expansion of both offshore and land-based wind farms. By providing high-quality, reliable main shafts, this market helps ensure that wind turbines can operate efficiently and effectively, contributing to the global transition to cleaner, more sustainable energy sources.

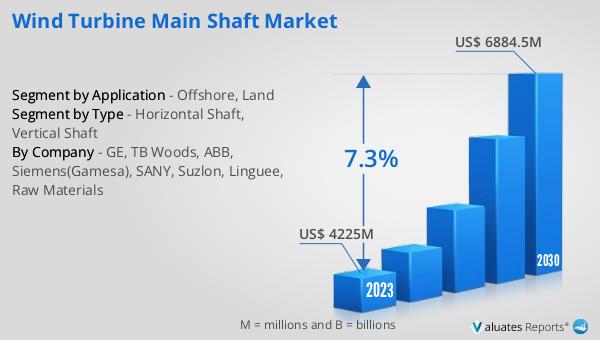

Global Wind Turbine Main Shaft Market Outlook:

The global Wind Turbine Main Shaft market was valued at US$ 4225 million in 2023 and is anticipated to reach US$ 6884.5 million by 2030, witnessing a CAGR of 7.3% during the forecast period 2024-2030. This significant growth reflects the increasing demand for wind energy as a sustainable and renewable energy source. As countries and companies strive to reduce their carbon footprints and transition to cleaner energy solutions, the need for efficient and reliable wind turbine components, such as main shafts, continues to grow. The market's expansion is driven by technological advancements aimed at improving the durability and performance of main shafts, as well as efforts to reduce production costs and enhance supply chain efficiency. The projected growth rate of 7.3% CAGR indicates a robust and steady increase in market value, highlighting the importance of wind energy in the global energy landscape. This growth is expected to be supported by ongoing investments in wind energy infrastructure, government incentives, and policies promoting renewable energy adoption. As the wind energy industry continues to evolve, the Global Wind Turbine Main Shaft Market is poised to play a critical role in supporting the development and expansion of wind farms worldwide.

| Report Metric | Details |

| Report Name | Wind Turbine Main Shaft Market |

| Accounted market size in 2023 | US$ 4225 million |

| Forecasted market size in 2030 | US$ 6884.5 million |

| CAGR | 7.3% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | GE, TB Woods, ABB, Siemens(Gamesa), SANY, Suzlon, Linguee, Raw Materials |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |