What is Global Medical Device Stability Testing Market?

The Global Medical Device Stability Testing Market is a specialized sector within the broader medical device industry that focuses on ensuring the durability and reliability of medical devices over time. Stability testing is crucial because it assesses how environmental factors such as temperature, humidity, and light exposure can affect the performance and safety of medical devices. This market encompasses a wide range of testing services and equipment designed to simulate real-world conditions and predict the lifespan of medical devices. By conducting these tests, manufacturers can ensure that their products meet regulatory standards and perform effectively throughout their intended shelf life. This is particularly important for devices that are implanted in the human body or used in critical care settings, where failure could have severe consequences. The market is driven by the increasing complexity of medical devices, stringent regulatory requirements, and the growing emphasis on patient safety. As a result, the Global Medical Device Stability Testing Market plays a vital role in the healthcare industry, helping to bring safe and effective medical devices to market.

Electromedical, Non-electromedical in the Global Medical Device Stability Testing Market:

Electromedical and non-electromedical devices are two broad categories within the Global Medical Device Stability Testing Market, each with its own unique testing requirements and challenges. Electromedical devices include equipment that relies on electrical power to function, such as pacemakers, defibrillators, and diagnostic imaging machines like MRI and CT scanners. These devices require rigorous stability testing to ensure that their electronic components can withstand various environmental stresses without compromising performance. For instance, electromagnetic interference (EMI) testing is crucial for electromedical devices to ensure they do not malfunction when exposed to other electronic devices. Additionally, battery life and power stability are critical factors that need to be tested to ensure the device can operate reliably over its intended lifespan. On the other hand, non-electromedical devices include a wide range of products such as surgical instruments, orthopedic implants, and wound care products. These devices do not rely on electrical power but still require extensive stability testing to ensure they can withstand physical stresses and environmental conditions. For example, surgical instruments must be tested for corrosion resistance and mechanical durability, while orthopedic implants need to be evaluated for their ability to withstand the mechanical stresses of the human body over time. Both categories of devices must also undergo biocompatibility testing to ensure they do not cause adverse reactions when in contact with human tissues. The testing protocols for electromedical and non-electromedical devices are governed by stringent regulatory standards set by organizations such as the FDA in the United States and the European Medicines Agency (EMA) in Europe. These standards ensure that all medical devices, whether electrical or non-electrical, meet the highest levels of safety and efficacy before they can be approved for market release. The increasing complexity of medical devices, coupled with the growing emphasis on patient safety, has led to a surge in demand for comprehensive stability testing services. This has, in turn, driven advancements in testing technologies and methodologies, making the Global Medical Device Stability Testing Market a dynamic and rapidly evolving sector.

Laboratory, Factory in the Global Medical Device Stability Testing Market:

The usage of the Global Medical Device Stability Testing Market spans various settings, including laboratories and factories, each with its own specific requirements and protocols. In laboratory settings, stability testing is often conducted under highly controlled conditions to simulate real-world environmental factors such as temperature, humidity, and light exposure. Laboratories are equipped with advanced testing equipment and technologies that allow for precise control and monitoring of these conditions. For example, climatic chambers are used to simulate different environmental conditions, while mechanical testing machines evaluate the physical durability of medical devices. Laboratory testing is crucial for identifying potential weaknesses in a device's design or materials before it goes into mass production. This preemptive approach helps manufacturers make necessary adjustments to improve the device's performance and safety. Additionally, laboratory testing is essential for meeting regulatory requirements, as it provides the data needed to demonstrate a device's stability and reliability over its intended shelf life. In factory settings, stability testing is integrated into the manufacturing process to ensure that each batch of medical devices meets the required standards of quality and performance. This involves both in-process testing and final product testing. In-process testing is conducted at various stages of the manufacturing process to identify and address any issues as they arise, thereby preventing defective products from reaching the market. Final product testing, on the other hand, involves subjecting the finished devices to rigorous stability tests to ensure they meet all regulatory and quality standards. Factories often employ automated testing systems to streamline this process and ensure consistency across large volumes of products. The integration of stability testing into the manufacturing process also helps in maintaining traceability and accountability, as each device can be tracked and verified for compliance with regulatory standards. This is particularly important for medical devices, where even minor defects can have serious implications for patient safety. Overall, the usage of stability testing in both laboratory and factory settings is essential for ensuring the safety, efficacy, and reliability of medical devices. By identifying and addressing potential issues early in the development and manufacturing process, stability testing helps manufacturers bring high-quality medical devices to market, ultimately contributing to better patient outcomes.

Global Medical Device Stability Testing Market Outlook:

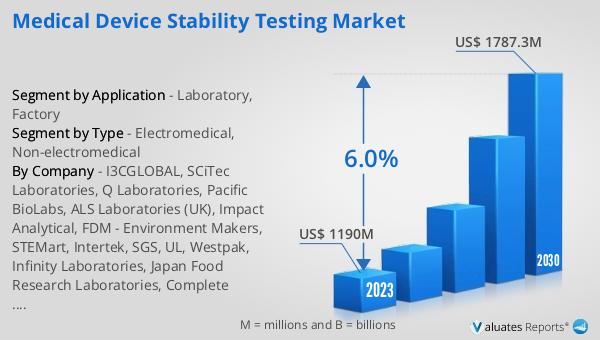

The global Medical Device Stability Testing market was valued at US$ 1190 million in 2023 and is anticipated to reach US$ 1787.3 million by 2030, witnessing a CAGR of 6.0% during the forecast period from 2024 to 2030. According to our research, the global market for medical devices is estimated at US$ 603 billion in the year 2023 and will be growing at a CAGR of 5% over the next six years. This growth is driven by the increasing complexity of medical devices, stringent regulatory requirements, and the growing emphasis on patient safety. The stability testing market plays a crucial role in this growth by ensuring that medical devices can withstand various environmental stresses and maintain their performance and safety over time. As the medical device industry continues to evolve, the demand for comprehensive stability testing services is expected to rise, making it a vital component of the healthcare sector.

| Report Metric | Details |

| Report Name | Medical Device Stability Testing Market |

| Accounted market size in 2023 | US$ 1190 million |

| Forecasted market size in 2030 | US$ 1787.3 million |

| CAGR | 6.0% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | I3CGLOBAL, SCiTec Laboratories, Q Laboratories, Pacific BioLabs, ALS Laboratories (UK), Impact Analytical, FDM - Environment Makers, STEMart, Intertek, SGS, UL, Westpak, Infinity Laboratories, Japan Food Research Laboratories, Complete Laboratory Solutions (CLS), NSF International |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |