What is Global Industrial Color Sensors Market?

The Global Industrial Color Sensors Market is a rapidly evolving sector that focuses on the development and deployment of sensors capable of detecting and differentiating colors in various industrial applications. These sensors are essential in numerous industries, including manufacturing, textiles, and printing, where precise color detection is crucial for quality control and operational efficiency. The market encompasses a wide range of sensor types, from simple single-channel sensors to more complex multi-channel systems, each designed to meet specific industrial needs. The growing demand for automation and the increasing emphasis on quality assurance in production processes are driving the expansion of this market. Additionally, advancements in sensor technology, such as improved accuracy and faster response times, are further propelling the adoption of industrial color sensors across different sectors. As industries continue to prioritize efficiency and precision, the Global Industrial Color Sensors Market is expected to witness significant growth in the coming years.

Single Channel, Multi-channel in the Global Industrial Color Sensors Market:

Single-channel and multi-channel sensors are two primary types of color sensors used in the Global Industrial Color Sensors Market, each serving distinct purposes based on the complexity and requirements of the application. Single-channel color sensors are designed to detect a single color or a specific range of colors. They are typically used in applications where the detection of a particular color is sufficient for the task at hand. For instance, in the packaging industry, single-channel sensors might be used to ensure that labels are correctly applied by detecting the presence of a specific color on the label. These sensors are generally simpler and more cost-effective, making them suitable for applications where high precision and multiple color detection are not critical. On the other hand, multi-channel color sensors are capable of detecting multiple colors simultaneously. They are equipped with multiple sensing elements, each tuned to a different color wavelength, allowing them to analyze a broader spectrum of colors. This capability makes them ideal for more complex applications where precise color differentiation is essential. For example, in the automotive industry, multi-channel sensors can be used to ensure that paint colors match exactly across different parts of a vehicle, maintaining consistency and quality. Multi-channel sensors are also prevalent in the textile industry, where they help in monitoring and controlling the dyeing process to achieve the desired color consistency across batches of fabric. The choice between single-channel and multi-channel sensors depends largely on the specific needs of the application. While single-channel sensors offer simplicity and cost savings, multi-channel sensors provide the versatility and precision required for more demanding tasks. As technology advances, the capabilities of both types of sensors continue to improve, offering better performance and reliability. In summary, the Global Industrial Color Sensors Market offers a range of solutions tailored to meet the diverse needs of various industries, from simple single-channel sensors for basic color detection to sophisticated multi-channel systems for complex color analysis.

Textile Industry, Manufacturing, Printing in the Global Industrial Color Sensors Market:

The usage of Global Industrial Color Sensors Market in the textile industry, manufacturing, and printing sectors highlights the versatility and importance of these sensors in ensuring quality and efficiency. In the textile industry, color sensors play a crucial role in the dyeing and finishing processes. They are used to monitor the color of fabrics in real-time, ensuring that the desired shades are consistently achieved across different batches. This not only helps in maintaining the quality of the final product but also reduces waste by minimizing the need for re-dyeing. Additionally, color sensors are used in the inspection of finished textiles to detect any color variations or defects, ensuring that only high-quality products reach the market. In the manufacturing sector, color sensors are employed in various applications to enhance quality control and streamline production processes. For instance, in the automotive industry, color sensors are used to ensure that paint colors on different parts of a vehicle match perfectly, maintaining a consistent appearance. They are also used in the assembly of electronic components, where they help in identifying and sorting parts based on color, ensuring that the correct components are used in the right places. This not only improves the efficiency of the assembly process but also reduces the likelihood of errors. In the printing industry, color sensors are essential for achieving accurate color reproduction. They are used to monitor the color output of printers in real-time, ensuring that the printed materials match the desired colors precisely. This is particularly important in applications such as packaging and branding, where color consistency is crucial for maintaining brand identity. Color sensors also help in detecting any color deviations or defects during the printing process, allowing for immediate adjustments to be made, thereby reducing waste and improving overall print quality. Overall, the Global Industrial Color Sensors Market plays a vital role in enhancing the quality and efficiency of various industrial processes. By providing accurate and reliable color detection, these sensors help industries maintain high standards of quality, reduce waste, and improve operational efficiency.

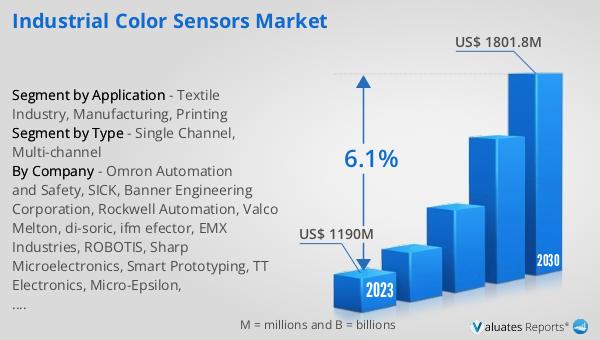

Global Industrial Color Sensors Market Outlook:

The global Industrial Color Sensors market was valued at US$ 1190 million in 2023 and is anticipated to reach US$ 1801.8 million by 2030, witnessing a CAGR of 6.1% during the forecast period from 2024 to 2030. This significant growth reflects the increasing demand for color sensors across various industries, driven by the need for improved quality control and automation. The market's expansion is also supported by advancements in sensor technology, which have enhanced the accuracy, speed, and reliability of color detection. As industries continue to prioritize efficiency and precision in their operations, the adoption of industrial color sensors is expected to rise, further fueling market growth. The versatility of these sensors, from single-channel to multi-channel systems, allows them to cater to a wide range of applications, from simple color detection tasks to complex color analysis. This adaptability makes them indispensable in sectors such as textiles, manufacturing, and printing, where maintaining color consistency and quality is paramount. The projected growth of the Global Industrial Color Sensors Market underscores the critical role these sensors play in modern industrial processes, highlighting their importance in achieving operational excellence and product quality.

| Report Metric | Details |

| Report Name | Industrial Color Sensors Market |

| Accounted market size in 2023 | US$ 1190 million |

| Forecasted market size in 2030 | US$ 1801.8 million |

| CAGR | 6.1% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Omron Automation and Safety, SICK, Banner Engineering Corporation, Rockwell Automation, Valco Melton, di-soric, ifm efector, EMX Industries, ROBOTIS, Sharp Microelectronics, Smart Prototyping, TT Electronics, Micro-Epsilon, Pepperl+Fuchs, Balluff, Leuze electronic, wenglor, Keyence, MAZeT, Kingbright Electronics |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |