What is Global Wire Bonding Machine Market?

The Global Wire Bonding Machine Market refers to the industry focused on the production and sale of machines used for wire bonding, a critical process in semiconductor and electronics manufacturing. Wire bonding machines are essential for connecting semiconductor chips to their packages or substrates using fine wires. These machines are widely used in the production of integrated circuits (ICs), microelectromechanical systems (MEMS), and other electronic components. The market encompasses various types of wire bonding machines, including manual, semi-automatic, and fully automatic models, each catering to different levels of production needs and automation requirements. The demand for wire bonding machines is driven by the growing electronics industry, advancements in semiconductor technology, and the increasing complexity of electronic devices. As technology continues to evolve, the need for more precise and efficient wire bonding solutions is expected to rise, further propelling the growth of the Global Wire Bonding Machine Market.

Fully Automatic, Semi-automatic in the Global Wire Bonding Machine Market:

Fully automatic and semi-automatic wire bonding machines play crucial roles in the Global Wire Bonding Machine Market, each offering distinct advantages and catering to different production needs. Fully automatic wire bonding machines are designed for high-volume production environments where speed, precision, and consistency are paramount. These machines are equipped with advanced features such as automated wire feeding, bonding, and cutting, which significantly reduce the need for manual intervention. They are capable of performing complex bonding tasks with high accuracy, making them ideal for large-scale semiconductor and electronics manufacturing. The automation in these machines ensures minimal human error, leading to higher yield rates and improved product quality. On the other hand, semi-automatic wire bonding machines strike a balance between automation and manual control. These machines require some level of operator involvement, particularly in the setup and alignment processes. However, they still offer automated bonding capabilities, which enhance efficiency compared to fully manual machines. Semi-automatic wire bonding machines are suitable for medium-scale production environments where flexibility and cost-effectiveness are important. They allow manufacturers to achieve a good level of precision and consistency while maintaining control over certain aspects of the bonding process. Both fully automatic and semi-automatic wire bonding machines are essential in the Global Wire Bonding Machine Market, catering to different segments of the industry based on production volume, complexity, and budget considerations. The choice between fully automatic and semi-automatic machines depends on various factors, including the specific requirements of the manufacturing process, the desired level of automation, and the available budget. As the demand for electronic devices continues to grow, the need for efficient and reliable wire bonding solutions will remain critical, driving the ongoing development and adoption of both fully automatic and semi-automatic wire bonding machines.

Semiconductor Industry, Electronics Manufacturing, Others in the Global Wire Bonding Machine Market:

The Global Wire Bonding Machine Market finds extensive usage in various sectors, including the semiconductor industry, electronics manufacturing, and other related fields. In the semiconductor industry, wire bonding machines are indispensable for the production of integrated circuits (ICs) and other semiconductor devices. These machines are used to create electrical connections between the semiconductor die and the package or substrate, ensuring the proper functioning of the device. The precision and reliability of wire bonding machines are crucial in this industry, as even minor defects can lead to significant performance issues in the final product. In electronics manufacturing, wire bonding machines are used to assemble a wide range of electronic components, including sensors, microelectromechanical systems (MEMS), and optoelectronic devices. The ability to create precise and reliable connections is essential for the performance and durability of these components. Wire bonding machines enable manufacturers to produce high-quality electronic devices that meet the stringent requirements of various applications, from consumer electronics to industrial and automotive systems. Beyond the semiconductor and electronics industries, wire bonding machines are also used in other fields where precise and reliable electrical connections are required. For example, in the medical device industry, wire bonding machines are used to assemble components for medical implants and diagnostic equipment. In the aerospace and defense sectors, these machines are used to produce high-reliability components for critical applications. The versatility and precision of wire bonding machines make them valuable tools in any industry where the performance and reliability of electronic connections are paramount. As technology continues to advance and the demand for sophisticated electronic devices grows, the usage of wire bonding machines in these various sectors is expected to increase, further driving the growth of the Global Wire Bonding Machine Market.

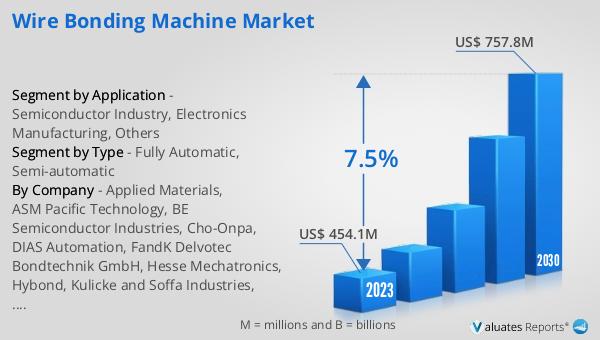

Global Wire Bonding Machine Market Outlook:

The global Wire Bonding Machine market was valued at US$ 454.1 million in 2023 and is anticipated to reach US$ 757.8 million by 2030, witnessing a CAGR of 7.5% during the forecast period 2024-2030. This market outlook highlights the significant growth potential of the wire bonding machine industry over the coming years. The increasing demand for advanced electronic devices, coupled with the ongoing advancements in semiconductor technology, is expected to drive the market's expansion. As manufacturers seek more efficient and precise bonding solutions to meet the growing complexity of electronic components, the adoption of wire bonding machines is likely to rise. The projected growth rate underscores the importance of wire bonding machines in the production of high-quality electronic devices and the critical role they play in various industries. With the market expected to nearly double in value by 2030, stakeholders in the wire bonding machine industry can anticipate substantial opportunities for innovation and development. The continuous evolution of technology and the increasing need for reliable and efficient bonding solutions will be key factors influencing the market's trajectory. As a result, the Global Wire Bonding Machine Market is poised for robust growth, driven by the ever-increasing demand for advanced electronic devices and the ongoing advancements in semiconductor manufacturing processes.

| Report Metric | Details |

| Report Name | Wire Bonding Machine Market |

| Accounted market size in 2023 | US$ 454.1 million |

| Forecasted market size in 2030 | US$ 757.8 million |

| CAGR | 7.5% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Applied Materials, ASM Pacific Technology, BE Semiconductor Industries, Cho-Onpa, DIAS Automation, FandK Delvotec Bondtechnik GmbH, Hesse Mechatronics, Hybond, Kulicke and Soffa Industries, Palomar Technologies, Shinkawa Electric, TPT, West Bond |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |