What is Global Mechanical Impurity Tester Market?

The Global Mechanical Impurity Tester Market is a specialized segment within the broader testing and measurement industry. This market focuses on devices and instruments designed to detect and measure mechanical impurities in various substances. Mechanical impurities refer to unwanted particles or contaminants that can affect the quality and performance of materials and products. These testers are crucial in ensuring that products meet stringent quality standards and regulatory requirements. They are widely used across multiple industries, including petroleum, chemical, electricity, commodity inspection, and scientific research. The market for these testers is driven by the increasing demand for high-quality products and the need for precise measurement and analysis of impurities. As industries continue to evolve and adopt more stringent quality control measures, the demand for mechanical impurity testers is expected to grow. These devices play a vital role in maintaining product integrity, ensuring safety, and enhancing overall performance. The market is characterized by continuous technological advancements, leading to the development of more sophisticated and accurate testing instruments.

Weight Method, Membrane Filtration in the Global Mechanical Impurity Tester Market:

The Weight Method and Membrane Filtration are two primary techniques used in the Global Mechanical Impurity Tester Market. The Weight Method involves measuring the weight of impurities present in a sample. This method is straightforward and involves filtering the sample through a pre-weighed filter paper. The filter paper captures the impurities, and the weight of the impurities is determined by comparing the weight of the filter paper before and after filtration. This method is widely used due to its simplicity and accuracy. It is particularly effective for detecting larger particles and is commonly used in industries where the presence of mechanical impurities can significantly impact product quality and performance. On the other hand, Membrane Filtration is a more advanced technique that involves passing the sample through a membrane filter with a specific pore size. The membrane filter captures impurities based on their size, allowing for the detection of even the smallest particles. This method is highly sensitive and can detect impurities that are not visible to the naked eye. It is widely used in industries where precision and accuracy are paramount, such as pharmaceuticals, biotechnology, and food and beverage. The Membrane Filtration method is also used in environmental testing to detect contaminants in water and air samples. Both methods have their advantages and are chosen based on the specific requirements of the application. The Weight Method is preferred for its simplicity and cost-effectiveness, while Membrane Filtration is chosen for its high sensitivity and ability to detect minute impurities. The choice of method depends on factors such as the type of sample, the size of impurities to be detected, and the required level of accuracy. In the Global Mechanical Impurity Tester Market, these methods are continually being refined and improved to meet the evolving needs of various industries. Technological advancements have led to the development of automated systems that enhance the efficiency and accuracy of these methods. These advancements include the use of advanced materials for filters, improved detection techniques, and the integration of digital technologies for data analysis and reporting. As industries continue to demand higher levels of quality and precision, the Weight Method and Membrane Filtration will remain essential techniques in the Global Mechanical Impurity Tester Market.

Petroleum, Chemical Industry, Electricity, Commodity Inspection, Scientific Research in the Global Mechanical Impurity Tester Market:

The Global Mechanical Impurity Tester Market finds extensive usage in various industries, including petroleum, chemical, electricity, commodity inspection, and scientific research. In the petroleum industry, mechanical impurity testers are crucial for ensuring the quality of crude oil and refined products. The presence of impurities in petroleum products can lead to equipment damage, reduced efficiency, and increased maintenance costs. By detecting and measuring impurities, these testers help in maintaining the quality and performance of petroleum products, ensuring smooth operations and reducing downtime. In the chemical industry, mechanical impurity testers are used to ensure the purity of raw materials and finished products. Impurities in chemicals can affect the quality and safety of products, leading to potential hazards and regulatory non-compliance. These testers help in identifying and quantifying impurities, ensuring that products meet stringent quality standards and regulatory requirements. In the electricity sector, mechanical impurity testers are used to ensure the quality of insulating oils and other materials used in electrical equipment. Impurities in insulating oils can lead to equipment failure, reduced efficiency, and increased maintenance costs. By detecting and measuring impurities, these testers help in maintaining the reliability and performance of electrical equipment, ensuring uninterrupted power supply. In the commodity inspection industry, mechanical impurity testers are used to ensure the quality and safety of various commodities, including food, beverages, and consumer goods. Impurities in these products can affect their quality, safety, and shelf life, leading to potential health hazards and regulatory non-compliance. These testers help in identifying and quantifying impurities, ensuring that products meet stringent quality standards and regulatory requirements. In scientific research, mechanical impurity testers are used to ensure the purity of samples and reagents used in experiments. Impurities in samples and reagents can affect the accuracy and reliability of experimental results, leading to potential errors and inconsistencies. These testers help in identifying and quantifying impurities, ensuring that samples and reagents meet the required purity standards and ensuring the accuracy and reliability of experimental results. Overall, the Global Mechanical Impurity Tester Market plays a crucial role in ensuring the quality, safety, and performance of products across various industries. By detecting and measuring impurities, these testers help in maintaining product integrity, ensuring regulatory compliance, and enhancing overall performance.

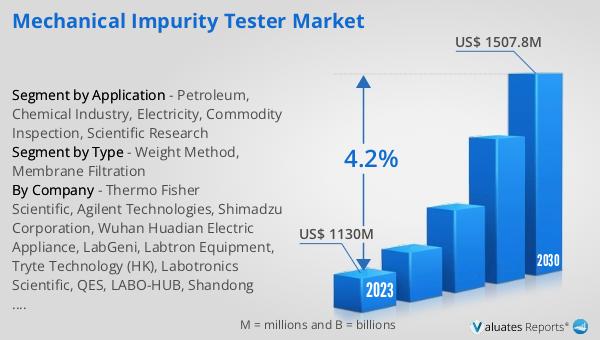

Global Mechanical Impurity Tester Market Outlook:

The global Mechanical Impurity Tester market was valued at US$ 1130 million in 2023 and is anticipated to reach US$ 1507.8 million by 2030, witnessing a CAGR of 4.2% during the forecast period 2024-2030. This market outlook indicates a steady growth trajectory driven by the increasing demand for high-quality products and stringent regulatory requirements across various industries. The growth is also attributed to continuous technological advancements in testing instruments, which enhance the accuracy and efficiency of impurity detection. As industries such as petroleum, chemical, electricity, commodity inspection, and scientific research continue to evolve, the need for precise measurement and analysis of mechanical impurities becomes more critical. The market's expansion is further supported by the growing emphasis on quality control and assurance, which necessitates the use of advanced testing equipment. The projected growth in the market underscores the importance of mechanical impurity testers in maintaining product quality, ensuring safety, and enhancing overall performance. As a result, manufacturers and suppliers of mechanical impurity testers are likely to invest in research and development to introduce more sophisticated and efficient testing solutions. This market outlook highlights the significant role of mechanical impurity testers in various industries and their contribution to achieving high standards of quality and performance.

| Report Metric | Details |

| Report Name | Mechanical Impurity Tester Market |

| Accounted market size in 2023 | US$ 1130 million |

| Forecasted market size in 2030 | US$ 1507.8 million |

| CAGR | 4.2% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Thermo Fisher Scientific, Agilent Technologies, Shimadzu Corporation, Wuhan Huadian Electric Appliance, LabGeni, Labtron Equipment, Tryte Technology (HK), Labotronics Scientific, QES, LABO-HUB, Shandong Shengtai Instruments, Kolery Instrument, Xiangyi Instrument, Liaoning Huake Petroleum Apparatus Science & Technology, North Dalian Analytical Instrument, Shandong Benchuang Instrument, Feixiu Instruments (Shanghai), Time Power |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |