What is Global Vertical Molding Gray Iron Castings Market?

The Global Vertical Molding Gray Iron Castings Market refers to the industry focused on producing gray iron castings using vertical molding techniques. Gray iron is a type of cast iron known for its high carbon content and excellent machinability, making it a popular choice for various industrial applications. Vertical molding is a casting process where the mold is oriented vertically, allowing for efficient production and high-quality castings. This market encompasses a wide range of products, including automotive parts, machinery components, and construction materials. The demand for gray iron castings is driven by their durability, cost-effectiveness, and versatility in different sectors. As industries continue to seek reliable and economical materials, the Global Vertical Molding Gray Iron Castings Market is expected to grow, providing essential components for various applications worldwide.

20 Class, 30 Class, 40 Class, 60 Class in the Global Vertical Molding Gray Iron Castings Market:

In the Global Vertical Molding Gray Iron Castings Market, different classes of gray iron castings are categorized based on their tensile strength and hardness. The 20 Class gray iron castings are known for their lower tensile strength, typically around 20,000 psi, making them suitable for applications where high strength is not a critical requirement. These castings are often used in non-load-bearing components such as pump housings, valve bodies, and light machinery parts. The 30 Class gray iron castings have a tensile strength of approximately 30,000 psi, offering a balance between strength and machinability. They are commonly used in automotive parts, agricultural equipment, and general machinery components. The 40 Class gray iron castings, with a tensile strength of around 40,000 psi, provide higher strength and wear resistance, making them ideal for more demanding applications such as heavy machinery, construction equipment, and mining tools. Finally, the 60 Class gray iron castings boast a tensile strength of about 60,000 psi, offering the highest strength and durability among the classes. These castings are used in critical applications where maximum strength and wear resistance are essential, such as in high-stress machinery parts, industrial equipment, and structural components. Each class of gray iron castings serves specific needs, ensuring that industries can choose the appropriate material based on their performance requirements and operational conditions.

Automotive, Agriculture, Construction and Mining, Machinery & Equipment, Municipal, Energy, Others in the Global Vertical Molding Gray Iron Castings Market:

The Global Vertical Molding Gray Iron Castings Market finds extensive usage across various industries due to the material's excellent properties and the efficiency of the vertical molding process. In the automotive sector, gray iron castings are used to manufacture engine blocks, brake components, and suspension parts, thanks to their durability and ability to withstand high temperatures and mechanical stress. In agriculture, these castings are utilized in the production of tractor parts, plowshares, and other farming equipment, providing the necessary strength and wear resistance for demanding agricultural operations. The construction and mining industries rely on gray iron castings for heavy machinery components, such as excavator parts, crusher frames, and construction equipment, where robustness and longevity are crucial. In the machinery and equipment sector, gray iron castings are used to produce machine tool bases, gear housings, and industrial machinery parts, benefiting from the material's stability and machinability. Municipal applications include the production of manhole covers, drainage grates, and other infrastructure components that require durability and resistance to environmental factors. The energy sector uses gray iron castings in the manufacturing of turbine housings, generator parts, and other energy production equipment, where reliability and performance are paramount. Additionally, gray iron castings are employed in various other industries, including railways, marine, and defense, for producing components that demand high strength and precision. The versatility and cost-effectiveness of gray iron castings make them an indispensable material across these diverse sectors, driving the growth and development of the Global Vertical Molding Gray Iron Castings Market.

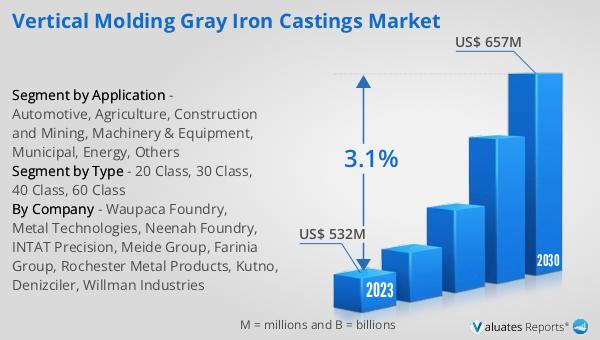

Global Vertical Molding Gray Iron Castings Market Outlook:

The global Vertical Molding Gray Iron Castings market was valued at US$ 532 million in 2023 and is anticipated to reach US$ 657 million by 2030, witnessing a CAGR of 3.1% during the forecast period 2024-2030. This market outlook indicates a steady growth trajectory for the industry, driven by the increasing demand for durable and cost-effective castings across various sectors. The projected growth reflects the ongoing advancements in vertical molding technology and the expanding applications of gray iron castings in automotive, construction, machinery, and other industries. As manufacturers continue to innovate and improve production processes, the market is expected to experience sustained growth, providing essential components for a wide range of applications. The anticipated increase in market value underscores the importance of gray iron castings in supporting industrial development and meeting the evolving needs of different sectors. With a focus on quality and efficiency, the Global Vertical Molding Gray Iron Castings Market is poised to play a crucial role in the global manufacturing landscape.

| Report Metric | Details |

| Report Name | Vertical Molding Gray Iron Castings Market |

| Accounted market size in 2023 | US$ 532 million |

| Forecasted market size in 2030 | US$ 657 million |

| CAGR | 3.1% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Waupaca Foundry, Metal Technologies, Neenah Foundry, INTAT Precision, Meide Group, Farinia Group, Rochester Metal Products, Kutno, Denizciler, Willman Industries |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |