What is Global Automotive Gray Iron Castings Market?

The Global Automotive Gray Iron Castings Market refers to the worldwide industry involved in the production and distribution of gray iron castings specifically for automotive applications. Gray iron, known for its excellent machinability, high thermal conductivity, and good vibration damping properties, is widely used in the automotive sector. This market encompasses a variety of components such as engine blocks, brake discs, and cylinder heads, which are essential for the functioning of both passenger and commercial vehicles. The market is driven by the increasing demand for durable and cost-effective materials in the automotive industry, as well as advancements in casting technologies that enhance the quality and performance of gray iron castings. The global reach of this market indicates its significance in supporting the automotive industry's growth and development across different regions.

Vertical Molding, Horizontal Molding in the Global Automotive Gray Iron Castings Market:

Vertical molding and horizontal molding are two primary methods used in the production of gray iron castings for the automotive industry. Vertical molding, also known as vertical flaskless molding, involves the use of vertically oriented molds. This method is highly efficient and suitable for high-volume production runs. The vertical orientation allows for continuous casting, which reduces cycle times and increases productivity. It is particularly advantageous for producing large quantities of small to medium-sized castings with consistent quality. The vertical molding process typically involves the use of automated molding machines that compact the sand around the pattern to form the mold cavity. This method is favored for its ability to produce castings with excellent dimensional accuracy and surface finish. On the other hand, horizontal molding, also known as horizontal flask molding, involves the use of horizontally oriented molds. This method is versatile and can accommodate a wide range of casting sizes and shapes. Horizontal molding is often used for producing larger castings that require more complex mold designs. The process involves placing the pattern horizontally in a flask, which is then filled with sand and compacted to form the mold cavity. Horizontal molding allows for greater flexibility in mold design and is suitable for both low and high-volume production runs. It is particularly beneficial for producing castings with intricate geometries and detailed features. Both vertical and horizontal molding methods have their own advantages and are chosen based on the specific requirements of the casting being produced. Vertical molding is preferred for its high efficiency and suitability for mass production, while horizontal molding offers greater versatility and flexibility in mold design. In the context of the global automotive gray iron castings market, both methods play a crucial role in meeting the diverse needs of the automotive industry. The choice between vertical and horizontal molding depends on factors such as the size and complexity of the casting, production volume, and desired quality attributes. The global automotive gray iron castings market relies on these molding methods to produce a wide range of components that are essential for the functioning of vehicles. Engine blocks, for example, are often produced using vertical molding due to the high volume and consistent quality required. Brake discs, on the other hand, may be produced using either vertical or horizontal molding depending on the specific design and production requirements. Cylinder heads, which require intricate geometries and detailed features, are typically produced using horizontal molding to achieve the desired level of precision and complexity. In summary, vertical molding and horizontal molding are two key methods used in the production of gray iron castings for the automotive industry. Each method has its own advantages and is chosen based on the specific requirements of the casting being produced. Vertical molding is highly efficient and suitable for high-volume production runs, while horizontal molding offers greater versatility and flexibility in mold design. Both methods play a crucial role in meeting the diverse needs of the global automotive gray iron castings market, ensuring the production of high-quality components that are essential for the functioning of vehicles.

Passenger Vehicle, Commercial Vehicle, Agricultural Machinery in the Global Automotive Gray Iron Castings Market:

The global automotive gray iron castings market finds extensive usage in various areas such as passenger vehicles, commercial vehicles, and agricultural machinery. In passenger vehicles, gray iron castings are commonly used for manufacturing engine blocks, brake discs, and cylinder heads. The excellent machinability and thermal conductivity of gray iron make it an ideal material for these components, ensuring efficient engine performance and reliable braking systems. The durability and cost-effectiveness of gray iron castings also contribute to their widespread use in passenger vehicles, where high performance and safety are paramount. In commercial vehicles, gray iron castings are used for a variety of components including engine blocks, brake drums, and suspension parts. The heavy-duty nature of commercial vehicles requires components that can withstand high levels of stress and wear. Gray iron castings provide the necessary strength and durability to meet these demands, ensuring the reliable operation of commercial vehicles over long distances and under challenging conditions. The ability of gray iron to dampen vibrations also enhances the comfort and safety of commercial vehicles, making it a preferred material for critical components. Agricultural machinery also benefits from the use of gray iron castings. Components such as engine blocks, transmission housings, and axle housings are commonly made from gray iron due to its excellent mechanical properties. The high strength and wear resistance of gray iron castings ensure the durability and longevity of agricultural machinery, which is often subjected to harsh operating conditions. The cost-effectiveness of gray iron also makes it an attractive choice for manufacturers of agricultural machinery, allowing them to produce high-quality components at a competitive price. In all these areas, the global automotive gray iron castings market plays a crucial role in supporting the production of reliable and high-performance vehicles and machinery. The use of gray iron castings ensures that critical components meet the necessary standards for strength, durability, and performance. As the demand for passenger vehicles, commercial vehicles, and agricultural machinery continues to grow, the importance of gray iron castings in these sectors is expected to remain significant. The versatility and cost-effectiveness of gray iron make it a valuable material for a wide range of applications, contributing to the overall growth and development of the automotive and machinery industries.

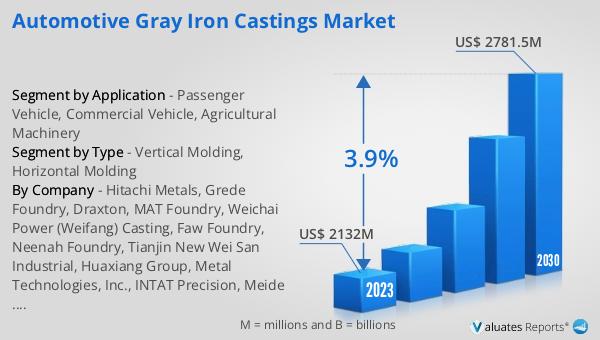

Global Automotive Gray Iron Castings Market Outlook:

The global automotive gray iron castings market was valued at US$ 2132 million in 2023 and is projected to reach US$ 2781.5 million by 2030, reflecting a compound annual growth rate (CAGR) of 3.9% during the forecast period from 2024 to 2030. This market outlook indicates a steady increase in demand for gray iron castings in the automotive industry, driven by the need for durable and cost-effective materials. The growth in market value underscores the importance of gray iron castings in the production of critical automotive components such as engine blocks, brake discs, and cylinder heads. The projected growth also highlights the advancements in casting technologies that enhance the quality and performance of gray iron castings, making them a preferred choice for automotive manufacturers. As the automotive industry continues to evolve, the demand for high-quality gray iron castings is expected to rise, supporting the overall growth of the market.

| Report Metric | Details |

| Report Name | Automotive Gray Iron Castings Market |

| Accounted market size in 2023 | US$ 2132 million |

| Forecasted market size in 2030 | US$ 2781.5 million |

| CAGR | 3.9% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Hitachi Metals, Grede Foundry, Draxton, MAT Foundry, Weichai Power (Weifang) Casting, Faw Foundry, Neenah Foundry, Tianjin New Wei San Industrial, Huaxiang Group, Metal Technologies, Inc., INTAT Precision, Meide Group, Farinia Group, Rochester Metal Products, Kutno |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |