What is Global Train Composite Brake Shoe Market?

The Global Train Composite Brake Shoe Market refers to the industry focused on the production and distribution of composite brake shoes used in trains. These brake shoes are essential components in the braking systems of trains, providing the necessary friction to slow down or stop the train. Unlike traditional cast iron brake shoes, composite brake shoes are made from a mixture of materials, including resins, fibers, and friction modifiers, which offer several advantages such as reduced wear on wheels, lower noise levels, and improved braking performance. The market for these products is driven by the increasing demand for efficient and reliable braking systems in both freight and passenger trains. Additionally, the push for more environmentally friendly and cost-effective solutions in the railway industry has further fueled the adoption of composite brake shoes. As rail networks continue to expand and modernize globally, the demand for high-quality composite brake shoes is expected to grow, making this market a crucial segment within the broader railway industry.

High Friction Coefficient Type, Low Friction Type in the Global Train Composite Brake Shoe Market:

In the Global Train Composite Brake Shoe Market, there are two main types of brake shoes based on their friction coefficients: High Friction Coefficient Type and Low Friction Type. High Friction Coefficient Type brake shoes are designed to provide maximum braking force, making them ideal for situations where strong and immediate braking is required. These brake shoes are typically used in high-speed trains and heavy freight trains, where the ability to stop quickly and safely is paramount. The materials used in high friction brake shoes are engineered to withstand high temperatures and pressures, ensuring consistent performance even under extreme conditions. On the other hand, Low Friction Type brake shoes are designed to offer a more gradual and controlled braking force. These are often used in passenger trains and light freight trains, where smooth and comfortable braking is more important than sheer stopping power. Low friction brake shoes help to reduce wear and tear on both the brake shoes and the train wheels, leading to longer service life and lower maintenance costs. The choice between high friction and low friction brake shoes depends on various factors, including the type of train, the operating conditions, and the specific requirements of the railway operator. Both types of brake shoes play a crucial role in ensuring the safety and efficiency of train operations, and advancements in materials science and engineering continue to improve their performance and durability.

Freight Trains, Passenger Trains in the Global Train Composite Brake Shoe Market:

The usage of composite brake shoes in the Global Train Composite Brake Shoe Market varies significantly between freight trains and passenger trains. In freight trains, composite brake shoes are essential for managing the heavy loads and long distances these trains typically cover. Freight trains often carry large quantities of goods, which means they require powerful braking systems to ensure safe and efficient operation. Composite brake shoes provide the necessary friction to slow down or stop these heavy trains, while also reducing wear on the wheels and minimizing maintenance costs. The durability and reliability of composite brake shoes make them an ideal choice for freight trains, which operate under demanding conditions and require consistent performance. In passenger trains, the focus is more on providing a smooth and comfortable ride for passengers. Composite brake shoes help achieve this by offering controlled and gradual braking, which reduces the jarring and noise associated with traditional cast iron brake shoes. This is particularly important in high-speed passenger trains, where sudden or harsh braking can be uncomfortable for passengers. Additionally, the reduced wear on wheels and lower maintenance requirements of composite brake shoes contribute to the overall efficiency and cost-effectiveness of passenger train operations. As rail networks continue to expand and modernize, the adoption of composite brake shoes in both freight and passenger trains is expected to increase, driven by the need for safer, more efficient, and environmentally friendly braking solutions.

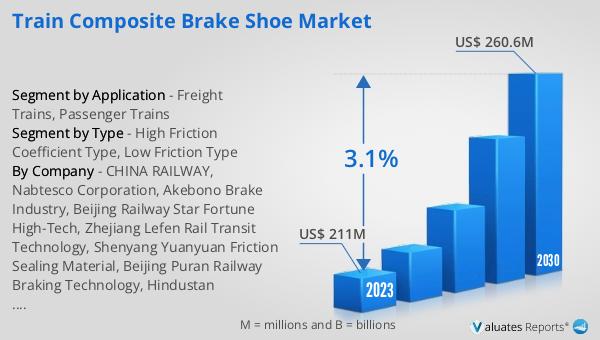

Global Train Composite Brake Shoe Market Outlook:

The global Train Composite Brake Shoe market was valued at US$ 211 million in 2023 and is anticipated to reach US$ 260.6 million by 2030, witnessing a CAGR of 3.1% during the forecast period from 2024 to 2030. This growth reflects the increasing demand for advanced braking solutions in the railway industry, driven by the need for improved safety, efficiency, and environmental sustainability. Composite brake shoes offer several advantages over traditional cast iron brake shoes, including reduced wear on wheels, lower noise levels, and better braking performance. These benefits are particularly important as rail networks continue to expand and modernize, requiring more reliable and cost-effective braking systems. The market's steady growth is also supported by advancements in materials science and engineering, which have led to the development of more durable and high-performance composite brake shoes. As a result, railway operators are increasingly adopting these advanced braking solutions to enhance the safety and efficiency of their operations.

| Report Metric | Details |

| Report Name | Train Composite Brake Shoe Market |

| Accounted market size in 2023 | US$ 211 million |

| Forecasted market size in 2030 | US$ 260.6 million |

| CAGR | 3.1% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | CHINA RAILWAY, Nabtesco Corporation, Akebono Brake Industry, Beijing Railway Star Fortune High-Tech, Zhejiang Lefen Rail Transit Technology, Shenyang Yuanyuan Friction Sealing Material, Beijing Puran Railway Braking Technology, Hindustan Composites, Wabtec Corporation |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |