What is Global Tube Decapping and Capping System Market?

The Global Tube Decapping and Capping System Market refers to the industry focused on the production and distribution of systems designed to automate the process of removing and replacing caps on tubes. These systems are essential in various sectors, including laboratories and manufacturing facilities, where precision and efficiency are crucial. The market encompasses a range of products, from fully automated machines to manual devices, catering to different operational needs and budgets. The demand for these systems is driven by the need for improved workflow efficiency, reduced contamination risks, and enhanced safety in handling tubes containing various substances. As industries continue to seek ways to optimize their processes, the Global Tube Decapping and Capping System Market is expected to grow, offering innovative solutions to meet the evolving needs of its diverse clientele.

Automatic, Manual in the Global Tube Decapping and Capping System Market:

In the Global Tube Decapping and Capping System Market, there are primarily two types of systems: automatic and manual. Automatic systems are designed to handle high volumes of tubes with minimal human intervention. These systems are equipped with advanced technologies such as robotics and sensors to ensure precise and consistent decapping and capping. They are ideal for large laboratories and factories where speed and accuracy are paramount. Automatic systems can significantly reduce the time required for these tasks, thereby increasing overall productivity. They also minimize the risk of contamination and human error, which is crucial in environments where the integrity of the samples or products is critical. On the other hand, manual systems require human operators to perform the decapping and capping tasks. These systems are generally more affordable and are suitable for smaller operations or facilities with lower throughput requirements. While they may not offer the same level of efficiency as automatic systems, manual systems provide greater control and flexibility, allowing operators to handle a variety of tube sizes and types. Both automatic and manual systems have their own set of advantages and are chosen based on the specific needs and constraints of the user. In summary, the choice between automatic and manual systems in the Global Tube Decapping and Capping System Market depends on factors such as volume, budget, and the level of precision required.

Laboratory, Factory in the Global Tube Decapping and Capping System Market:

The usage of Global Tube Decapping and Capping Systems in laboratories and factories highlights their versatility and importance in different settings. In laboratories, these systems are crucial for handling biological samples, chemicals, and other sensitive materials. Automated decapping and capping systems in labs ensure that samples are processed quickly and accurately, reducing the risk of contamination and human error. This is particularly important in high-throughput environments such as clinical laboratories, research institutions, and pharmaceutical companies, where the integrity of samples is paramount. The ability to automate these tasks allows lab personnel to focus on more complex and value-added activities, thereby enhancing overall productivity and efficiency. In factories, tube decapping and capping systems are used in various manufacturing processes, including the production of pharmaceuticals, food and beverages, and industrial chemicals. These systems help streamline the production process by ensuring that tubes are securely capped and decapped, preventing leaks and contamination. Automated systems are especially beneficial in large-scale manufacturing operations where speed and consistency are critical. They help maintain product quality and safety, which are essential for meeting regulatory standards and customer expectations. Manual systems, while less efficient than automated ones, are still valuable in smaller factories or for specialized tasks that require a higher degree of control and customization. Overall, the application of tube decapping and capping systems in both laboratories and factories underscores their role in enhancing operational efficiency, ensuring product quality, and maintaining safety standards.

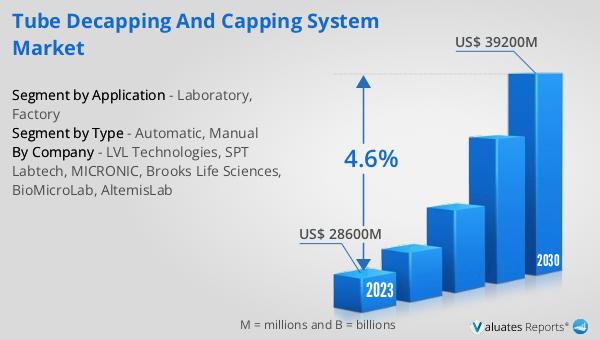

Global Tube Decapping and Capping System Market Outlook:

The global Tube Decapping and Capping System market was valued at US$ 28,600 million in 2023 and is anticipated to reach US$ 39,200 million by 2030, witnessing a CAGR of 4.6% during the forecast period from 2024 to 2030. This growth reflects the increasing demand for efficient and reliable systems to handle the decapping and capping of tubes in various industries. The market's expansion is driven by the need for automation and precision in laboratories and manufacturing facilities, where these systems play a critical role in maintaining the integrity of samples and products. As industries continue to evolve and seek ways to optimize their processes, the demand for advanced tube decapping and capping systems is expected to rise, contributing to the market's steady growth.

| Report Metric | Details |

| Report Name | Tube Decapping and Capping System Market |

| Accounted market size in 2023 | US$ 28600 million |

| Forecasted market size in 2030 | US$ 39200 million |

| CAGR | 4.6% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | LVL Technologies, SPT Labtech, MICRONIC, Brooks Life Sciences, BioMicroLab, AltemisLab |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |