What is Global Blender for the Pharmaceutical Industry Market?

The Global Blender for the Pharmaceutical Industry Market refers to the worldwide demand and supply of blenders specifically designed for use in the pharmaceutical sector. These blenders are essential for mixing various ingredients to create medications, ensuring uniformity and consistency in the final product. The market encompasses a range of blender types, including fixed and mobile blenders, each catering to different needs within the industry. Factors driving the market include the increasing demand for pharmaceutical products, advancements in blender technology, and stringent regulations requiring high-quality production standards. The market is characterized by a diverse array of manufacturers and suppliers, each offering innovative solutions to meet the specific needs of pharmaceutical companies. As the pharmaceutical industry continues to grow, the demand for efficient and reliable blenders is expected to rise, making this market a critical component of the global healthcare landscape.

Fixed, Mobile in the Global Blender for the Pharmaceutical Industry Market:

Fixed and mobile blenders play a crucial role in the Global Blender for the Pharmaceutical Industry Market, each offering unique advantages and applications. Fixed blenders are stationary units typically installed in a dedicated area within a pharmaceutical manufacturing facility. These blenders are known for their robust construction and high capacity, making them ideal for large-scale production. They are designed to handle significant volumes of ingredients, ensuring thorough mixing and uniformity in the final product. Fixed blenders often come with advanced features such as automated controls, precise mixing parameters, and integrated cleaning systems, which enhance their efficiency and ease of use. On the other hand, mobile blenders offer flexibility and versatility, as they can be easily moved and used in different locations within a facility. These blenders are particularly useful for smaller batches or pilot production runs, where the ability to quickly switch between different formulations is essential. Mobile blenders are typically more compact and lightweight compared to fixed units, making them easier to transport and store. They also often feature modular designs, allowing for easy customization and adaptation to specific production needs. Both fixed and mobile blenders are designed to meet stringent regulatory standards, ensuring that they provide safe and reliable mixing solutions for pharmaceutical applications. The choice between fixed and mobile blenders depends on various factors, including the scale of production, the specific requirements of the manufacturing process, and the available space within the facility. In many cases, pharmaceutical companies may use a combination of both types of blenders to optimize their production processes and achieve the desired level of efficiency and flexibility. Overall, the availability of both fixed and mobile blenders in the market provides pharmaceutical manufacturers with a wide range of options to meet their specific needs and enhance their production capabilities.

Pharmaceutical, Chemical Industry in the Global Blender for the Pharmaceutical Industry Market:

The usage of Global Blenders in the Pharmaceutical Industry is extensive and multifaceted, playing a vital role in the production of various medications. In the pharmaceutical sector, blenders are used to mix active pharmaceutical ingredients (APIs) with excipients to create uniform and consistent formulations. This process is crucial for ensuring that each dose of medication contains the correct amount of active ingredients, which is essential for efficacy and safety. Blenders are also used in the production of tablets, capsules, and other dosage forms, where precise mixing is required to achieve the desired physical and chemical properties. In the chemical industry, blenders are used for mixing raw materials to create a wide range of chemical products, including solvents, adhesives, and coatings. The ability to achieve uniform mixing is critical in the chemical industry, as it directly impacts the quality and performance of the final product. Blenders used in the chemical industry are designed to handle a variety of materials, including powders, granules, and liquids, and are often equipped with features such as variable speed controls and specialized mixing blades to ensure optimal performance. The versatility and efficiency of blenders make them indispensable tools in both the pharmaceutical and chemical industries, where they contribute to the production of high-quality products that meet stringent regulatory standards. The demand for advanced blenders is expected to continue growing as these industries evolve and expand, driven by the need for innovative and efficient production solutions.

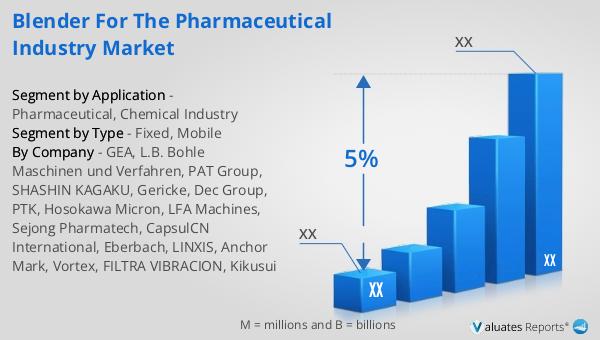

Global Blender for the Pharmaceutical Industry Market Outlook:

The global pharmaceutical market was valued at approximately 1,475 billion USD in 2022, experiencing a steady growth rate with a compound annual growth rate (CAGR) of 5% projected over the next six years. In comparison, the chemical drug market has shown significant growth as well, increasing from 1,005 billion USD in 2018 to an estimated 1,094 billion USD in 2022. This growth in both markets underscores the increasing demand for pharmaceutical and chemical products, driven by factors such as advancements in medical research, rising healthcare needs, and the development of new and innovative drugs. The expanding market for pharmaceutical products highlights the critical role of efficient and reliable production equipment, such as blenders, in meeting the growing demand. As pharmaceutical companies strive to enhance their production capabilities and maintain high-quality standards, the need for advanced blenders designed specifically for the pharmaceutical industry is expected to rise. This trend reflects the broader growth and evolution of the global healthcare and chemical sectors, emphasizing the importance of technological innovation and regulatory compliance in driving market expansion.

| Report Metric | Details |

| Report Name | Blender for the Pharmaceutical Industry Market |

| CAGR | 5% |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | GEA, L.B. Bohle Maschinen und Verfahren, PAT Group, SHASHIN KAGAKU, Gericke, Dec Group, PTK, Hosokawa Micron, LFA Machines, Sejong Pharmatech, CapsulCN International, Eberbach, LINXIS, Anchor Mark, Vortex, FILTRA VIBRACION, Kikusui |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |