What is Global Touch-trigger Touch Probe Market?

The Global Touch-trigger Touch Probe Market is a specialized segment within the broader industrial automation and precision measurement industry. Touch-trigger probes are devices used in coordinate measuring machines (CMMs), machine tools, and other precision measurement equipment to detect the exact position of a workpiece. These probes are essential for ensuring high accuracy in manufacturing processes, as they help in measuring the dimensions and geometries of various components. The market for these probes is driven by the increasing demand for precision engineering and quality control in industries such as automotive, aerospace, and electronics. As manufacturing processes become more complex and the need for high-precision components grows, the adoption of touch-trigger probes is expected to rise. These probes are designed to be highly sensitive and accurate, capable of detecting minute deviations in the dimensions of a workpiece. They play a crucial role in maintaining the quality and consistency of manufactured products, thereby reducing waste and improving efficiency. The global market for touch-trigger probes is characterized by continuous technological advancements, with manufacturers focusing on developing more advanced and reliable probes to meet the evolving needs of various industries.

Threaded installation, Autojoint Connector in the Global Touch-trigger Touch Probe Market:

Threaded installation and Autojoint Connector are two critical aspects of the Global Touch-trigger Touch Probe Market. Threaded installation refers to the method of attaching the touch probe to the machine tool or CMM using a threaded interface. This type of installation is known for its robustness and reliability, ensuring that the probe remains securely attached during the measurement process. The threaded interface allows for easy installation and removal of the probe, making it convenient for operators to switch between different probes as needed. This flexibility is particularly important in manufacturing environments where different types of measurements are required for various components. On the other hand, the Autojoint Connector is a more advanced method of attaching the touch probe to the machine. This type of connector allows for quick and easy attachment and detachment of the probe without the need for any tools. The Autojoint Connector is designed to provide a secure and stable connection, ensuring that the probe remains accurately positioned during the measurement process. This type of connector is particularly useful in automated manufacturing environments where speed and efficiency are critical. The Autojoint Connector also allows for the use of multiple probes on a single machine, enabling operators to quickly switch between different probes as needed. This flexibility can significantly improve the efficiency of the measurement process, reducing downtime and increasing productivity. Both threaded installation and Autojoint Connector play a crucial role in the performance and reliability of touch-trigger probes, ensuring that they can provide accurate and consistent measurements in a wide range of applications.

Workpiece Measurement, Optical Measurement in the Global Touch-trigger Touch Probe Market:

The usage of Global Touch-trigger Touch Probe Market in workpiece measurement and optical measurement is extensive and varied. In workpiece measurement, touch-trigger probes are used to measure the dimensions and geometries of various components with high precision. These probes are capable of detecting minute deviations in the dimensions of a workpiece, ensuring that the manufactured components meet the required specifications. This is particularly important in industries such as automotive and aerospace, where the quality and accuracy of components are critical. The touch-trigger probes are used in coordinate measuring machines (CMMs) and machine tools to perform precise measurements of the workpiece, ensuring that it meets the required tolerances. The probes can measure various features of the workpiece, such as holes, slots, and surfaces, providing accurate and reliable data that can be used to improve the manufacturing process. In optical measurement, touch-trigger probes are used in conjunction with optical measurement systems to provide high-precision measurements of components. These probes are capable of measuring the dimensions and geometries of components with high accuracy, ensuring that they meet the required specifications. The touch-trigger probes are used in optical measurement systems to perform precise measurements of the workpiece, ensuring that it meets the required tolerances. The probes can measure various features of the workpiece, such as holes, slots, and surfaces, providing accurate and reliable data that can be used to improve the manufacturing process. The use of touch-trigger probes in optical measurement systems is particularly important in industries such as electronics and medical devices, where the quality and accuracy of components are critical. The touch-trigger probes provide high-precision measurements that can be used to ensure the quality and reliability of the manufactured components, reducing waste and improving efficiency.

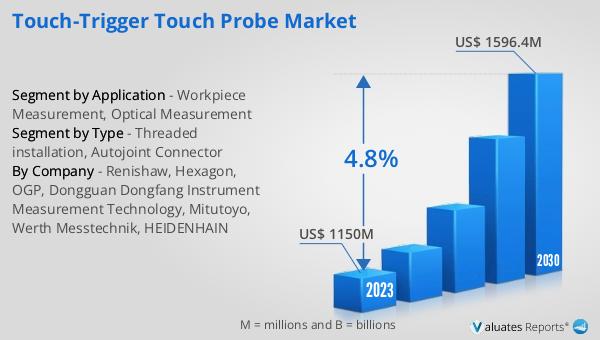

Global Touch-trigger Touch Probe Market Outlook:

The global Touch-trigger Touch Probe market was valued at US$ 1150 million in 2023 and is anticipated to reach US$ 1596.4 million by 2030, witnessing a CAGR of 4.8% during the forecast period 2024-2030. This growth is driven by the increasing demand for precision engineering and quality control in various industries such as automotive, aerospace, and electronics. As manufacturing processes become more complex and the need for high-precision components grows, the adoption of touch-trigger probes is expected to rise. These probes are designed to be highly sensitive and accurate, capable of detecting minute deviations in the dimensions of a workpiece. They play a crucial role in maintaining the quality and consistency of manufactured products, thereby reducing waste and improving efficiency. The market is characterized by continuous technological advancements, with manufacturers focusing on developing more advanced and reliable probes to meet the evolving needs of various industries. The increasing adoption of automation in manufacturing processes is also expected to drive the demand for touch-trigger probes, as they provide accurate and reliable measurements that are essential for maintaining the quality and consistency of manufactured products. The market is also expected to benefit from the growing demand for high-precision components in emerging industries such as medical devices and electronics, where the quality and accuracy of components are critical. Overall, the global Touch-trigger Touch Probe market is expected to witness significant growth during the forecast period, driven by the increasing demand for precision engineering and quality control in various industries.

| Report Metric | Details |

| Report Name | Touch-trigger Touch Probe Market |

| Accounted market size in 2023 | US$ 1150 million |

| Forecasted market size in 2030 | US$ 1596.4 million |

| CAGR | 4.8% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Renishaw, Hexagon, OGP, Dongguan Dongfang Instrument Measurement Technology, Mitutoyo, Werth Messtechnik, HEIDENHAIN |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |