What is Global Polymer Processing Aids (PPAs) Market?

The Global Polymer Processing Aids (PPAs) Market refers to the industry focused on the production and application of additives that enhance the processing of polymers. These aids are crucial in improving the efficiency and quality of polymer manufacturing processes. PPAs are used to reduce issues such as melt fracture, die build-up, and gel formation during the extrusion and molding of polymers. By doing so, they help in achieving smoother surfaces, better clarity, and improved mechanical properties in the final products. The market for PPAs is driven by the increasing demand for high-quality polymer products in various industries such as packaging, automotive, construction, and electronics. The growing emphasis on sustainability and the need for energy-efficient manufacturing processes also contribute to the rising adoption of PPAs. As industries continue to innovate and develop new polymer materials, the demand for effective processing aids is expected to grow, making the Global Polymer Processing Aids Market a vital component of the broader polymer industry.

Polypropylene, Polyethylene, PVC, ABS, Others in the Global Polymer Processing Aids (PPAs) Market:

Polypropylene, Polyethylene, PVC, ABS, and other polymers are significant segments within the Global Polymer Processing Aids (PPAs) Market. Polypropylene (PP) is a versatile polymer widely used in packaging, automotive parts, textiles, and consumer goods. PPAs in polypropylene processing help in reducing melt fracture and improving surface finish, which is crucial for applications requiring high aesthetic quality. Polyethylene (PE), another major polymer, is used extensively in packaging films, containers, and pipes. PPAs in polyethylene processing enhance the extrusion process, leading to better film clarity, reduced die build-up, and improved mechanical properties. Polyvinyl Chloride (PVC) is used in construction materials, pipes, and medical devices. PPAs in PVC processing help in achieving smoother surfaces and reducing defects, which is essential for applications like medical tubing and high-quality construction profiles. Acrylonitrile Butadiene Styrene (ABS) is known for its toughness and impact resistance, making it suitable for automotive parts, consumer electronics, and toys. PPAs in ABS processing improve flow properties and surface appearance, ensuring high-quality end products. Other polymers, such as polystyrene, polycarbonate, and nylon, also benefit from the use of PPAs. These aids help in reducing processing issues and enhancing the overall quality of the final products. The use of PPAs across these diverse polymer types highlights their importance in the polymer industry, driving innovation and improving manufacturing efficiency.

Packaging Materials, Pipe & Tube, Wire and Cable, Other in the Global Polymer Processing Aids (PPAs) Market:

The usage of Global Polymer Processing Aids (PPAs) Market in various applications such as packaging materials, pipe & tube, wire and cable, and others is extensive and crucial for achieving high-quality end products. In packaging materials, PPAs play a vital role in improving the clarity, surface finish, and mechanical properties of films and containers. They help in reducing melt fracture and die build-up during the extrusion process, leading to smoother and more transparent films. This is particularly important for food packaging, where clarity and surface quality are essential for consumer appeal. In the pipe & tube industry, PPAs are used to enhance the extrusion process, resulting in smoother surfaces and reduced defects. This is critical for applications such as water and gas pipes, where surface quality and durability are paramount. PPAs help in achieving consistent wall thickness and reducing the occurrence of gels and other imperfections. In the wire and cable industry, PPAs are used to improve the extrusion of polymer coatings, ensuring smooth and uniform insulation layers. This is essential for maintaining the electrical properties and durability of the cables. PPAs help in reducing die build-up and improving the flow properties of the polymer, leading to higher-quality insulation. Other applications of PPAs include automotive parts, consumer electronics, and construction materials. In these industries, PPAs help in achieving high-quality surfaces, improved mechanical properties, and better processing efficiency. The use of PPAs in these diverse applications highlights their importance in the polymer industry, driving innovation and improving the quality of end products.

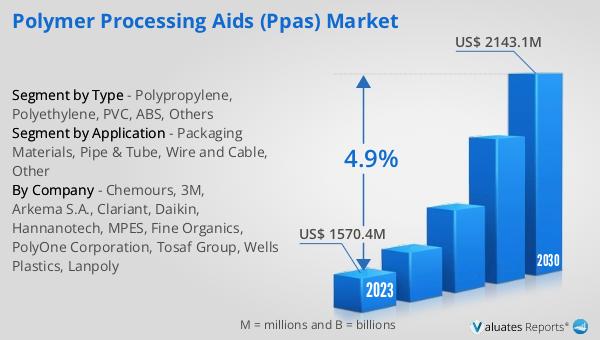

Global Polymer Processing Aids (PPAs) Market Outlook:

The global Polymer Processing Aids (PPAs) market was valued at US$ 1570.4 million in 2023 and is projected to reach US$ 2143.1 million by 2030, reflecting a compound annual growth rate (CAGR) of 4.9% during the forecast period from 2024 to 2030. This growth is driven by the increasing demand for high-quality polymer products across various industries, including packaging, automotive, construction, and electronics. The rising emphasis on sustainability and energy-efficient manufacturing processes also contributes to the growing adoption of PPAs. As industries continue to innovate and develop new polymer materials, the demand for effective processing aids is expected to grow, making the Global Polymer Processing Aids Market a vital component of the broader polymer industry.

| Report Metric | Details |

| Report Name | Polymer Processing Aids (PPAs) Market |

| Accounted market size in 2023 | US$ 1570.4 million |

| Forecasted market size in 2030 | US$ 2143.1 million |

| CAGR | 4.9% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Chemours, 3M, Arkema S.A., Clariant, Daikin, Hannanotech, MPES, Fine Organics, PolyOne Corporation, Tosaf Group, Wells Plastics, Lanpoly |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |