What is Global Acrylic Impact Modifier (ACR) Market?

The Global Acrylic Impact Modifier (ACR) Market is a specialized segment within the broader chemical industry, focusing on the production and distribution of acrylic-based additives that enhance the impact resistance of various plastic products. These modifiers are crucial in improving the durability and performance of plastics, making them more resistant to cracking and breaking under stress. ACRs are widely used in industries such as automotive, construction, consumer electronics, and home appliances, where the mechanical properties of plastics are critical. The market is driven by the increasing demand for high-performance materials that can withstand harsh conditions and mechanical stress. Technological advancements and innovations in polymer science have further propelled the growth of the ACR market, enabling the development of more efficient and effective impact modifiers. The global reach of this market is extensive, with significant contributions from regions like North America, Europe, and Asia-Pacific, reflecting the widespread application and importance of ACRs in modern manufacturing and engineering.

Purity: Below 99.0%, Purity: 99.0% to 99.5%, Purity: Above 99.5% in the Global Acrylic Impact Modifier (ACR) Market:

In the Global Acrylic Impact Modifier (ACR) Market, purity levels play a significant role in determining the quality and application of the product. Purity levels are typically categorized into three main segments: below 99.0%, 99.0% to 99.5%, and above 99.5%. Each of these purity levels has distinct characteristics and applications. ACRs with purity below 99.0% are generally used in applications where extreme precision and high performance are not critical. These lower-purity modifiers are cost-effective and suitable for general-purpose applications, providing adequate impact resistance for everyday plastic products. On the other hand, ACRs with purity levels between 99.0% and 99.5% offer a balanced combination of performance and cost. These modifiers are commonly used in industries that require a higher degree of impact resistance and durability, such as automotive and construction. They provide enhanced mechanical properties without significantly increasing production costs. The highest purity level, above 99.5%, represents the premium segment of the market. These ACRs are used in high-end applications where superior performance is essential. Industries such as aerospace, medical devices, and high-performance electronics often require these high-purity modifiers to ensure the highest levels of reliability and durability. The production of high-purity ACRs involves advanced manufacturing processes and stringent quality control measures to achieve the desired level of purity. This segment of the market is characterized by higher production costs but offers significant benefits in terms of performance and longevity of the end products. The choice of purity level depends on the specific requirements of the application, with higher purity levels generally associated with more demanding and specialized uses. The global market for ACRs is diverse, with manufacturers offering a range of products to meet the varying needs of different industries. The availability of different purity levels allows manufacturers to select the most appropriate modifier for their specific application, balancing performance, cost, and other factors. As the demand for high-performance materials continues to grow, the importance of purity in the ACR market is likely to increase, driving further innovation and development in this field.

Automobile, Architectural Engineering, Consumer Electronics and Home Appliances, Others in the Global Acrylic Impact Modifier (ACR) Market:

The usage of Global Acrylic Impact Modifier (ACR) Market spans across various industries, including automobile, architectural engineering, consumer electronics, and home appliances, among others. In the automobile industry, ACRs are essential for enhancing the durability and impact resistance of plastic components used in vehicles. These modifiers help in improving the performance of parts such as bumpers, dashboards, and interior trims, making them more resistant to mechanical stress and environmental factors. The use of ACRs in automotive applications contributes to the overall safety and longevity of vehicles, ensuring that plastic components can withstand the rigors of daily use and harsh conditions. In architectural engineering, ACRs play a crucial role in the construction of durable and resilient building materials. They are used in the production of impact-resistant windows, doors, and other structural components, providing enhanced safety and performance. The ability of ACRs to improve the mechanical properties of plastics makes them ideal for use in construction materials that need to withstand high impact and stress. This is particularly important in regions prone to extreme weather conditions or seismic activity, where the durability of building materials is critical. In the consumer electronics industry, ACRs are used to enhance the impact resistance of plastic housings and components. This is particularly important for devices such as smartphones, tablets, and laptops, which are subject to frequent handling and potential drops. The use of ACRs helps in protecting these devices from damage, ensuring their longevity and reliability. Additionally, ACRs are used in the production of high-performance electronic components that require superior mechanical properties. In the home appliances sector, ACRs are used to improve the durability and performance of plastic components in products such as refrigerators, washing machines, and microwaves. These modifiers help in enhancing the impact resistance of plastic parts, ensuring that they can withstand the wear and tear of daily use. The use of ACRs in home appliances contributes to the overall quality and longevity of these products, providing consumers with reliable and durable solutions. Beyond these specific industries, ACRs are also used in various other applications where enhanced impact resistance and durability are required. This includes packaging materials, medical devices, and industrial equipment, among others. The versatility and effectiveness of ACRs make them a valuable component in a wide range of products, driving their demand across different sectors. The global reach of the ACR market reflects its importance in modern manufacturing and engineering, with significant contributions from regions such as North America, Europe, and Asia-Pacific.

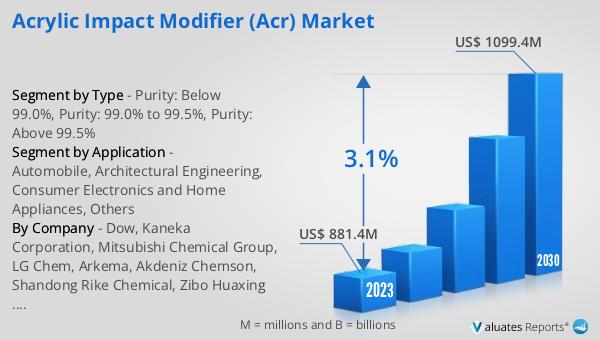

Global Acrylic Impact Modifier (ACR) Market Outlook:

The global Acrylic Impact Modifier (ACR) market was valued at US$ 881.4 million in 2023 and is projected to reach US$ 1099.4 million by 2030, reflecting a compound annual growth rate (CAGR) of 3.1% during the forecast period from 2024 to 2030. This growth is indicative of the increasing demand for high-performance materials that can enhance the durability and impact resistance of plastic products across various industries. The market's expansion is driven by technological advancements, innovations in polymer science, and the growing need for materials that can withstand mechanical stress and harsh conditions. Notably, three key regions have made significant contributions to the market, accounting for approximately 67% of the total share in the European region. This substantial share underscores the importance of ACRs in the European market, where industries such as automotive, construction, and consumer electronics heavily rely on these modifiers to improve the performance and longevity of their products. The widespread application and critical role of ACRs in enhancing the mechanical properties of plastics highlight the market's significance and potential for continued growth.

| Report Metric | Details |

| Report Name | Acrylic Impact Modifier (ACR) Market |

| Accounted market size in 2023 | US$ 881.4 million |

| Forecasted market size in 2030 | US$ 1099.4 million |

| CAGR | 3.1% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Dow, Kaneka Corporation, Mitsubishi Chemical Group, LG Chem, Arkema, Akdeniz Chemson, Shandong Rike Chemical, Zibo Huaxing Additives, Anqiu Donghai Plastic Industry, Nippon Paint Professionals, WSD Chemical, FCFC, INEOS Styrolution, Shine Polymer |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |