What is Global Vacuum Heat Treatment Furnace Systems Market?

The Global Vacuum Heat Treatment Furnace Systems Market refers to the industry that manufactures and sells specialized furnaces used for heat treatment processes under vacuum conditions. These systems are essential in various industries for enhancing the mechanical properties of materials, such as metals and alloys, by subjecting them to controlled heating and cooling cycles in a vacuum environment. The vacuum condition helps in preventing oxidation and contamination, ensuring high-quality treatment results. These furnaces are widely used in sectors like automotive, aerospace, tool and die, and electronics, where precision and material integrity are crucial. The market encompasses a range of furnace types, including single chamber, double chamber, and multi-chamber systems, each designed to meet specific industrial requirements. The demand for these systems is driven by the need for advanced manufacturing processes and the growing emphasis on high-performance materials. As industries continue to evolve and adopt more sophisticated technologies, the Global Vacuum Heat Treatment Furnace Systems Market is expected to witness significant growth.

Single Chamber, Double Chamber, Multi Chamber in the Global Vacuum Heat Treatment Furnace Systems Market:

Single chamber vacuum heat treatment furnace systems are designed for processes that require a single, enclosed space for heating and cooling. These systems are typically used for smaller-scale operations or specific applications where the entire process can be completed within one chamber. The single chamber design offers simplicity and ease of operation, making it suitable for applications that do not require complex processing steps. On the other hand, double chamber vacuum heat treatment furnace systems feature two separate chambers, usually one for heating and the other for cooling. This design allows for more efficient processing as the material can be transferred from the heating chamber to the cooling chamber without exposure to the external environment, thus maintaining the vacuum condition. Double chamber systems are ideal for applications that require rapid cooling or where the material needs to be kept in a controlled atmosphere throughout the process. Multi-chamber vacuum heat treatment furnace systems take this concept further by incorporating multiple chambers, each dedicated to different stages of the heat treatment process. These systems are highly versatile and can handle complex processing requirements, making them suitable for large-scale industrial applications. The multi-chamber design allows for continuous processing, where materials can move through various stages of heating, soaking, and cooling without interruption. This not only enhances efficiency but also ensures consistent quality and performance of the treated materials. In the Global Vacuum Heat Treatment Furnace Systems Market, the choice between single, double, and multi-chamber systems depends on the specific needs of the application, the scale of operation, and the desired outcomes. Each type of system offers unique advantages, and manufacturers often choose the one that best aligns with their production goals and technical requirements.

Automotive, Tool & Die in the Global Vacuum Heat Treatment Furnace Systems Market:

The usage of Global Vacuum Heat Treatment Furnace Systems in the automotive industry is pivotal for producing high-performance components that meet stringent quality standards. These systems are used to treat various automotive parts, such as gears, crankshafts, and engine components, to enhance their strength, durability, and resistance to wear and tear. The vacuum environment ensures that the heat treatment process is free from oxidation and contamination, resulting in superior quality parts that can withstand the demanding conditions of automotive applications. In the tool and die industry, vacuum heat treatment furnace systems are essential for producing tools and dies with exceptional hardness and precision. These systems are used to treat materials like high-speed steel and carbide, which are commonly used in cutting tools, molds, and dies. The vacuum heat treatment process enhances the mechanical properties of these materials, making them more resistant to deformation and wear. This is crucial for maintaining the accuracy and longevity of tools and dies, which are subjected to high levels of stress during operation. The ability to achieve precise control over the heat treatment process in a vacuum environment ensures that the treated tools and dies meet the exact specifications required for high-performance applications. Overall, the Global Vacuum Heat Treatment Furnace Systems Market plays a critical role in supporting the automotive and tool and die industries by providing advanced solutions for enhancing the performance and reliability of key components.

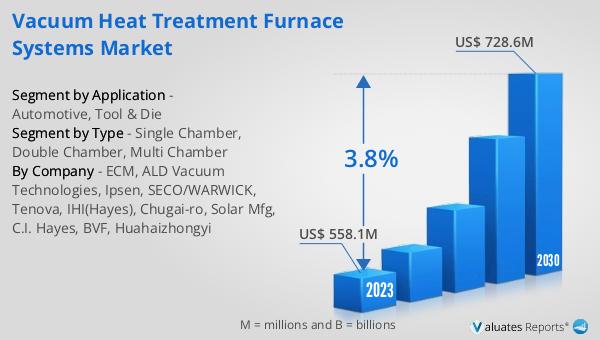

Global Vacuum Heat Treatment Furnace Systems Market Outlook:

The global market for Vacuum Heat Treatment Furnace Systems was valued at $558.1 million in 2023 and is projected to reach $728.6 million by 2030, reflecting a compound annual growth rate (CAGR) of 3.8% during the forecast period from 2024 to 2030. The top three companies in this market collectively hold approximately 34% of the market share. This growth is driven by the increasing demand for high-quality heat treatment processes across various industries, including automotive, aerospace, and electronics. The vacuum heat treatment furnace systems are essential for achieving precise control over the heating and cooling cycles, which is crucial for enhancing the mechanical properties of materials. The market's expansion is also supported by advancements in technology and the growing emphasis on high-performance materials. As industries continue to evolve and adopt more sophisticated manufacturing processes, the demand for vacuum heat treatment furnace systems is expected to rise, further driving the market's growth.

| Report Metric | Details |

| Report Name | Vacuum Heat Treatment Furnace Systems Market |

| Accounted market size in 2023 | US$ 558.1 million |

| Forecasted market size in 2030 | US$ 728.6 million |

| CAGR | 3.8% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | ECM, ALD Vacuum Technologies, Ipsen, SECO/WARWICK, Tenova, IHI(Hayes), Chugai-ro, Solar Mfg, C.I. Hayes, BVF, Huahaizhongyi |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |