What is Global Multi Point Chromatic Confocal Sensor Market?

The Global Multi Point Chromatic Confocal Sensor Market is a specialized segment within the broader field of optical sensors. These sensors are designed to measure distances and surface profiles with high precision by using the principle of chromatic confocal technology. This technology involves splitting white light into its constituent colors and focusing them at different depths. When the light reflects back from the surface, the sensor can determine the exact distance based on the color of the reflected light. This method allows for highly accurate, non-contact measurements, making it ideal for applications requiring meticulous detail. The market for these sensors is growing due to their increasing adoption in various industries such as semiconductor manufacturing, electronics, and precision engineering. The sensors are valued for their ability to provide real-time data and their versatility in measuring both 2D and 3D surfaces. As industries continue to demand higher precision and efficiency, the Global Multi Point Chromatic Confocal Sensor Market is expected to expand further, driven by technological advancements and the need for more accurate measurement solutions.

2D, 3D in the Global Multi Point Chromatic Confocal Sensor Market:

In the context of the Global Multi Point Chromatic Confocal Sensor Market, 2D and 3D measurements play crucial roles in various industrial applications. 2D measurements involve capturing the surface profile of an object in two dimensions, which is essential for tasks such as surface roughness analysis, flatness measurement, and edge detection. These measurements are typically used in quality control processes where the surface characteristics of a product need to be inspected to ensure they meet specific standards. On the other hand, 3D measurements provide a more comprehensive view by capturing the depth information along with the surface profile. This is particularly important in applications where the shape, volume, and dimensions of an object need to be measured with high precision. For instance, in semiconductor manufacturing, 3D measurements are used to inspect the intricate patterns on silicon wafers, ensuring that each layer is correctly aligned and free of defects. Similarly, in the automotive industry, 3D measurements are used to inspect engine components, ensuring they meet the stringent tolerances required for optimal performance. The ability to measure in three dimensions also allows for more complex analyses, such as determining the wear and tear on mechanical parts over time. The versatility of Multi Point Chromatic Confocal Sensors in providing both 2D and 3D measurements makes them invaluable tools in modern manufacturing and quality control processes. These sensors can be integrated into automated inspection systems, providing real-time data that can be used to make immediate adjustments to the manufacturing process, thereby reducing waste and improving efficiency. As industries continue to push the boundaries of precision and miniaturization, the demand for advanced measurement solutions like Multi Point Chromatic Confocal Sensors is expected to grow. The ability to capture detailed 2D and 3D measurements not only enhances product quality but also enables manufacturers to innovate and develop new products with greater complexity and functionality.

Semiconductor Manufacturing, 3C Electronics, Glass Manufacturing, Precision Machined Parts, New Energy Battery, Others in the Global Multi Point Chromatic Confocal Sensor Market:

The usage of Global Multi Point Chromatic Confocal Sensors spans across various industries, each benefiting from the high precision and versatility these sensors offer. In semiconductor manufacturing, these sensors are crucial for inspecting silicon wafers, ensuring that each layer is perfectly aligned and free from defects. The ability to measure both 2D and 3D surfaces allows for detailed analysis of the intricate patterns on the wafers, which is essential for producing high-quality semiconductors. In the 3C electronics industry, which includes computers, communications, and consumer electronics, these sensors are used to inspect components such as circuit boards and connectors. The high precision of the sensors ensures that each component meets the required specifications, reducing the risk of product failures. In glass manufacturing, Multi Point Chromatic Confocal Sensors are used to measure the thickness and flatness of glass sheets, ensuring they meet the stringent quality standards required for applications such as smartphone screens and optical lenses. The sensors' ability to provide real-time data allows for immediate adjustments to the manufacturing process, improving efficiency and reducing waste. In the production of precision machined parts, these sensors are used to inspect the dimensions and surface quality of components, ensuring they meet the tight tolerances required for applications such as aerospace and medical devices. The sensors' ability to measure complex geometries in three dimensions makes them ideal for this industry. In the new energy battery industry, these sensors are used to inspect the electrodes and separators in lithium-ion batteries, ensuring they are free from defects that could affect battery performance. The sensors' high precision and ability to provide real-time data are crucial for maintaining the quality and reliability of these batteries. Other industries that benefit from Multi Point Chromatic Confocal Sensors include automotive, where they are used to inspect engine components and other critical parts, and the pharmaceutical industry, where they are used to inspect the surface quality of tablets and capsules. The versatility and precision of these sensors make them invaluable tools in a wide range of applications, driving their adoption across various industries.

Global Multi Point Chromatic Confocal Sensor Market Outlook:

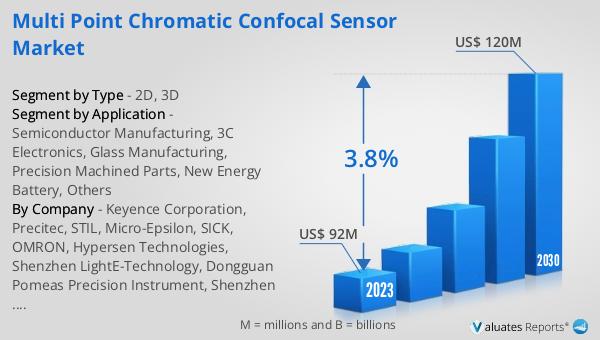

The global Multi Point Chromatic Confocal Sensor market was valued at US$ 92 million in 2023 and is anticipated to reach US$ 120 million by 2030, witnessing a CAGR of 3.8% during the forecast period from 2024 to 2030. This market outlook indicates a steady growth trajectory driven by the increasing demand for high-precision measurement solutions across various industries. The adoption of these sensors is expected to rise as industries continue to seek ways to improve product quality and manufacturing efficiency. The ability of Multi Point Chromatic Confocal Sensors to provide accurate, real-time data makes them essential tools in modern manufacturing processes. As technological advancements continue to enhance the capabilities of these sensors, their application scope is likely to expand further, contributing to the market's growth. The projected growth in the market value reflects the increasing recognition of the benefits these sensors offer, including improved product quality, reduced waste, and enhanced manufacturing efficiency. The steady CAGR of 3.8% underscores the growing importance of precision measurement solutions in various industries, from semiconductor manufacturing to automotive and beyond. As industries continue to innovate and develop more complex products, the demand for advanced measurement technologies like Multi Point Chromatic Confocal Sensors is expected to remain strong, driving the market's growth in the coming years.

| Report Metric | Details |

| Report Name | Multi Point Chromatic Confocal Sensor Market |

| Accounted market size in 2023 | US$ 92 million |

| Forecasted market size in 2030 | US$ 120 million |

| CAGR | 3.8% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Keyence Corporation, Precitec, STIL, Micro-Epsilon, SICK, OMRON, Hypersen Technologies, Shenzhen LightE-Technology, Dongguan Pomeas Precision Instrument, Shenzhen Shenshi Intelligent Technology, Think Focus, Proldv Optical Technology, Creative Visual Intellgence |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |