What is Global Vacuum Carburizing Furnace Systems Market?

The Global Vacuum Carburizing Furnace Systems Market is a specialized segment within the industrial furnace industry, focusing on advanced heat treatment processes. Vacuum carburizing is a method used to harden the surface of metal parts, enhancing their durability and performance. This process involves heating the metal in a vacuum environment and introducing a carbon-rich gas, which diffuses into the metal's surface. The result is a hardened layer that significantly improves wear resistance and fatigue strength. These systems are crucial in industries where high-performance materials are essential, such as automotive, aerospace, and tool manufacturing. The market for these systems is driven by the increasing demand for high-quality, durable components that can withstand extreme conditions. As industries continue to push the boundaries of material performance, the need for advanced heat treatment solutions like vacuum carburizing furnace systems is expected to grow. This market is characterized by technological advancements, with manufacturers continually developing more efficient and effective systems to meet the evolving needs of their customers.

Single Chamber, Double Chamber, Multi Chamber in the Global Vacuum Carburizing Furnace Systems Market:

Single Chamber, Double Chamber, and Multi Chamber vacuum carburizing furnace systems each offer unique advantages and are suited to different industrial applications. Single Chamber systems are the simplest and most cost-effective option, ideal for smaller operations or those with limited space. These systems perform all stages of the carburizing process within a single chamber, making them easy to operate and maintain. However, they may not be as efficient as multi-chamber systems, particularly for high-volume production. Double Chamber systems, on the other hand, separate the heating and carburizing stages into two distinct chambers. This separation allows for better control over the process parameters, leading to more consistent and higher-quality results. Double Chamber systems are often used in medium to large-scale operations where precision and efficiency are critical. Multi Chamber systems represent the most advanced and versatile option, featuring multiple chambers for different stages of the carburizing process. These systems can handle high volumes of parts simultaneously, making them ideal for large-scale industrial applications. The ability to process multiple batches at once significantly reduces cycle times and increases overall productivity. Multi Chamber systems also offer the highest level of process control, ensuring uniform carburizing and optimal material properties. Each type of system has its own set of advantages and is chosen based on the specific needs and constraints of the operation. As the demand for high-performance materials continues to grow, the choice of vacuum carburizing furnace system will play a crucial role in determining the efficiency and quality of the heat treatment process.

Automotive, Tool & Die in the Global Vacuum Carburizing Furnace Systems Market:

The usage of Global Vacuum Carburizing Furnace Systems in the automotive and tool & die industries highlights their critical role in modern manufacturing. In the automotive industry, these systems are used to enhance the performance and longevity of various components, such as gears, shafts, and bearings. The vacuum carburizing process ensures that these parts have a hardened surface, which significantly improves their wear resistance and fatigue strength. This is particularly important in the automotive sector, where components are subjected to high stress and extreme conditions. By using vacuum carburizing furnace systems, manufacturers can produce parts that meet the stringent quality and performance standards required in the industry. In the tool & die industry, vacuum carburizing furnace systems are used to harden the surfaces of tools and dies, which are essential for shaping and forming materials in manufacturing processes. The hardened surface provided by the vacuum carburizing process ensures that these tools and dies can withstand the high pressures and repeated use typical in industrial applications. This results in longer tool life and reduced maintenance costs, which are crucial for maintaining productivity and efficiency in manufacturing operations. The ability to produce high-quality, durable tools and dies is a significant advantage for manufacturers, allowing them to meet the demands of their customers and stay competitive in the market. Overall, the use of vacuum carburizing furnace systems in these industries underscores their importance in producing high-performance, durable components that are essential for modern manufacturing.

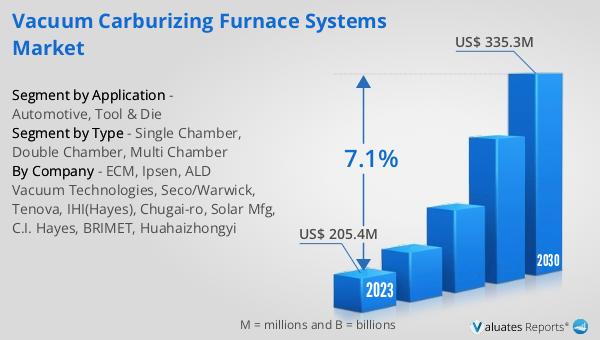

Global Vacuum Carburizing Furnace Systems Market Outlook:

The global Vacuum Carburizing Furnace Systems market was valued at US$ 205.4 million in 2023 and is anticipated to reach US$ 335.3 million by 2030, witnessing a CAGR of 7.1% during the forecast period 2024-2030. Asia Pacific vacuum carburizing furnace sales share the largest, accounting for 52% of the world. Europe accounts for 23%, North America has 18% of the market, and other regions have smaller shares. ECM is the world's leading enterprise, accounting for 23% of global revenue share. The top five global manufacturers account for 74 percent.

| Report Metric | Details |

| Report Name | Vacuum Carburizing Furnace Systems Market |

| Accounted market size in 2023 | US$ 205.4 million |

| Forecasted market size in 2030 | US$ 335.3 million |

| CAGR | 7.1% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | ECM, Ipsen, ALD Vacuum Technologies, Seco/Warwick, Tenova, IHI(Hayes), Chugai-ro, Solar Mfg, C.I. Hayes, BRIMET, Huahaizhongyi |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |