What is Global PPDI Type Polyurethane Elastomer Market?

The Global PPDI Type Polyurethane Elastomer Market refers to the worldwide industry focused on the production and distribution of polyurethane elastomers that are based on para-phenylene diisocyanate (PPDI). These elastomers are known for their exceptional mechanical properties, including high tensile strength, excellent abrasion resistance, and superior flexibility. They are widely used in various applications due to their durability and performance under extreme conditions. The market encompasses a range of products and services, from raw materials and chemical formulations to finished goods and technical support. The demand for PPDI type polyurethane elastomers is driven by their versatility and effectiveness in industries such as automotive, construction, and manufacturing. As global industries continue to evolve and seek advanced materials for improved performance and sustainability, the PPDI type polyurethane elastomer market is expected to grow, offering innovative solutions to meet diverse industrial needs.

Low Free PPDI Polyurethane Elastomers, other in the Global PPDI Type Polyurethane Elastomer Market:

Low Free PPDI Polyurethane Elastomers are a specialized subset within the broader Global PPDI Type Polyurethane Elastomer Market. These elastomers are characterized by their low free isocyanate content, which makes them safer and more environmentally friendly compared to traditional polyurethane elastomers. The reduction in free isocyanates minimizes the potential for hazardous emissions during manufacturing and application, thereby enhancing workplace safety and reducing environmental impact. Low Free PPDI Polyurethane Elastomers maintain the high-performance characteristics of standard PPDI elastomers, such as excellent mechanical strength, abrasion resistance, and flexibility. They are particularly suitable for applications where stringent environmental and safety regulations are in place. Industries such as automotive, aerospace, and medical devices benefit from these elastomers due to their reduced toxicity and compliance with health and safety standards. The development of Low Free PPDI Polyurethane Elastomers is a response to the growing demand for sustainable and safer materials in industrial applications. Manufacturers are investing in research and development to create formulations that offer the same or improved performance while minimizing health risks and environmental impact. This innovation is crucial for industries that prioritize sustainability and worker safety. The use of Low Free PPDI Polyurethane Elastomers also aligns with global trends towards greener manufacturing processes and products. As regulations become more stringent and consumer awareness about environmental issues increases, the adoption of these elastomers is expected to rise. Companies that incorporate Low Free PPDI Polyurethane Elastomers into their products can gain a competitive edge by offering safer and more sustainable solutions. The market for these elastomers is likely to expand as more industries recognize the benefits of reducing free isocyanate content in their materials. In summary, Low Free PPDI Polyurethane Elastomers represent a significant advancement in the polyurethane elastomer market, addressing the need for high-performance materials that are also safer and more environmentally friendly. Their development and adoption are driven by regulatory requirements, industry standards, and the growing emphasis on sustainability and safety in industrial applications.

Machine Made, Achitecture, Tire Manufacturing, Others in the Global PPDI Type Polyurethane Elastomer Market:

The Global PPDI Type Polyurethane Elastomer Market finds extensive usage in various sectors, including machine-made products, architecture, tire manufacturing, and other industries. In machine-made products, these elastomers are valued for their durability and resistance to wear and tear. They are used in the production of seals, gaskets, and other components that require high mechanical strength and flexibility. The ability of PPDI type polyurethane elastomers to withstand harsh operating conditions makes them ideal for use in heavy machinery and industrial equipment. In the field of architecture, these elastomers are used in coatings, sealants, and adhesives. Their excellent weather resistance and durability make them suitable for exterior applications, where they can protect buildings and structures from environmental damage. The flexibility and strength of PPDI type polyurethane elastomers also make them ideal for use in expansion joints and other architectural elements that require movement and flexibility. In tire manufacturing, PPDI type polyurethane elastomers are used to enhance the performance and durability of tires. They are used in the production of tire treads and other components that require high abrasion resistance and mechanical strength. The use of these elastomers in tires helps to improve their lifespan and performance, making them more reliable and cost-effective for consumers. Other industries that benefit from the use of PPDI type polyurethane elastomers include the automotive, aerospace, and medical device sectors. In the automotive industry, these elastomers are used in the production of various components, including bushings, mounts, and suspension parts. Their high mechanical strength and resistance to wear and tear make them ideal for use in vehicles that operate under extreme conditions. In the aerospace industry, PPDI type polyurethane elastomers are used in the production of seals, gaskets, and other components that require high performance and reliability. Their ability to withstand extreme temperatures and harsh operating conditions makes them suitable for use in aircraft and spacecraft. In the medical device sector, these elastomers are used in the production of various components, including catheters, tubing, and seals. Their biocompatibility and resistance to chemicals make them ideal for use in medical applications. Overall, the Global PPDI Type Polyurethane Elastomer Market plays a crucial role in various industries, providing high-performance materials that enhance the durability, reliability, and safety of products.

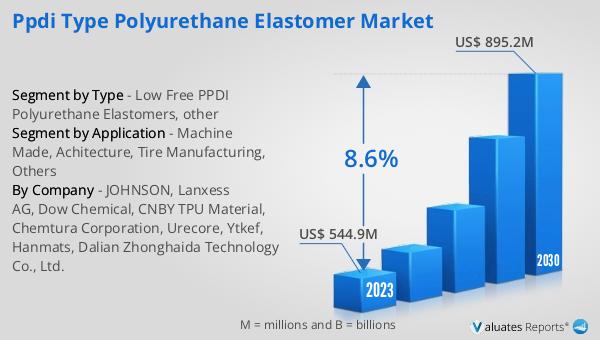

Global PPDI Type Polyurethane Elastomer Market Outlook:

The global PPDI Type Polyurethane Elastomer market was valued at US$ 544.9 million in 2023 and is anticipated to reach US$ 895.2 million by 2030, witnessing a CAGR of 8.6% during the forecast period 2024-2030. This significant growth reflects the increasing demand for high-performance materials across various industries. The market's expansion is driven by the unique properties of PPDI type polyurethane elastomers, which offer superior mechanical strength, flexibility, and resistance to wear and tear. These characteristics make them ideal for use in demanding applications, from automotive and aerospace to construction and medical devices. As industries continue to seek advanced materials that can enhance the performance and durability of their products, the demand for PPDI type polyurethane elastomers is expected to rise. The market's growth is also supported by ongoing research and development efforts aimed at improving the properties and applications of these elastomers. Companies are investing in innovative formulations and manufacturing processes to meet the evolving needs of their customers and comply with stringent environmental and safety regulations. The increasing focus on sustainability and the development of Low Free PPDI Polyurethane Elastomers further contribute to the market's positive outlook. Overall, the global PPDI Type Polyurethane Elastomer market is poised for significant growth, driven by the demand for high-performance materials and the continuous advancements in elastomer technology.

| Report Metric | Details |

| Report Name | PPDI Type Polyurethane Elastomer Market |

| Accounted market size in 2023 | US$ 544.9 million |

| Forecasted market size in 2030 | US$ 895.2 million |

| CAGR | 8.6% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | JOHNSON, Lanxess AG, Dow Chemical, CNBY TPU Material, Chemtura Corporation, Urecore, Ytkef, Hanmats, Dalian Zhonghaida Technology Co., Ltd. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |