What is Global Sintered Porous Filter Market?

The Global Sintered Porous Filter Market refers to the worldwide industry focused on the production and distribution of sintered porous filters. These filters are created through a process called sintering, where powdered materials are heated to just below their melting point until they bond together, forming a solid structure with tiny, interconnected pores. This unique structure allows the filters to effectively trap and remove particles from gases and liquids, making them highly valuable in various applications. The market encompasses a wide range of industries, including water treatment, petroleum and chemical processing, pharmaceuticals, and more. As industries continue to seek efficient and reliable filtration solutions, the demand for sintered porous filters is expected to grow, driven by their durability, high filtration efficiency, and ability to withstand harsh operating conditions.

Cartridge Sintered Porous Filter, Disc Sintered Porous Filter, Cup Sintered Porous Filter, Lid Sintered Porous Filter in the Global Sintered Porous Filter Market:

Cartridge Sintered Porous Filters are cylindrical filters designed for easy installation and replacement in filtration systems. They are commonly used in applications requiring high flow rates and fine filtration, such as water treatment and chemical processing. These filters offer a large surface area for filtration, ensuring efficient removal of contaminants while maintaining a steady flow of the filtered medium. Disc Sintered Porous Filters, on the other hand, are flat, circular filters that are often used in laboratory settings and industrial processes where precise filtration is required. Their compact design allows for easy integration into various equipment and systems, making them ideal for applications where space is limited. Cup Sintered Porous Filters are cup-shaped filters that provide a larger filtration area compared to disc filters. They are typically used in applications where a higher volume of fluid needs to be filtered, such as in the food and beverage industry or in large-scale water treatment plants. These filters are known for their robustness and ability to handle high-pressure environments. Lid Sintered Porous Filters are designed to fit over containers or vessels, providing a secure and efficient filtration solution. They are often used in applications where the filtered medium needs to be protected from external contaminants, such as in pharmaceutical manufacturing or chemical processing. Each type of sintered porous filter offers unique advantages, making them suitable for a wide range of applications across various industries.

Water Treatment, Petroleum and Chemical, Pharmaceutical, Others in the Global Sintered Porous Filter Market:

The usage of Global Sintered Porous Filter Market in water treatment is extensive, as these filters are highly effective in removing impurities and contaminants from water. They are used in municipal water treatment plants to ensure the supply of clean and safe drinking water. In industrial settings, sintered porous filters are employed to treat wastewater, removing harmful substances before the water is discharged back into the environment. In the petroleum and chemical industries, these filters play a crucial role in the purification of various fluids and gases. They are used to remove particulate matter, ensuring the quality and purity of the final products. In the pharmaceutical industry, sintered porous filters are essential for maintaining the sterility and purity of drugs and other medical products. They are used in the production of sterile solutions, filtration of active pharmaceutical ingredients, and in the manufacturing of medical devices. Other industries that benefit from the use of sintered porous filters include the food and beverage industry, where they are used to ensure the safety and quality of products, and the electronics industry, where they are used in the production of semiconductors and other electronic components. The versatility and efficiency of sintered porous filters make them an indispensable tool in various applications, contributing to the overall growth and development of the Global Sintered Porous Filter Market.

Global Sintered Porous Filter Market Outlook:

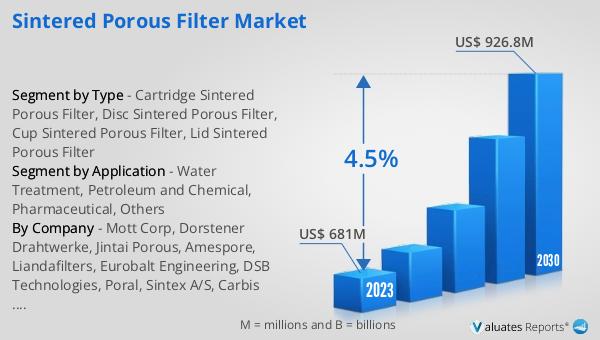

The global Sintered Porous Filter market was valued at US$ 681 million in 2023 and is anticipated to reach US$ 926.8 million by 2030, witnessing a CAGR of 4.5% during the forecast period 2024-2030. This significant growth can be attributed to the increasing demand for efficient and reliable filtration solutions across various industries. As more industries recognize the benefits of sintered porous filters, such as their durability, high filtration efficiency, and ability to withstand harsh operating conditions, the market is expected to expand further. The continuous advancements in filtration technology and the development of new and improved sintered porous filters are also contributing to the market's growth. With the rising awareness of environmental concerns and the need for sustainable solutions, the demand for sintered porous filters is likely to increase, driving the market forward.

| Report Metric | Details |

| Report Name | Sintered Porous Filter Market |

| Accounted market size in 2023 | US$ 681 million |

| Forecasted market size in 2030 | US$ 926.8 million |

| CAGR | 4.5% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Mott Corp, Dorstener Drahtwerke, Jintai Porous, Amespore, Liandafilters, Eurobalt Engineering, DSB Technologies, Poral, Sintex A/S, Carbis Filtration Ltd |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |