What is Global Rapid Prototyping in Aerospace and Defense Market?

Global Rapid Prototyping in Aerospace and Defense Market involves the use of advanced manufacturing technologies to create scale models of parts or assemblies quickly and efficiently. This process is crucial in the aerospace and defense sectors, where precision and innovation are paramount. Rapid prototyping allows engineers and designers to test and refine their ideas before committing to full-scale production, reducing the risk of costly errors. It encompasses various techniques such as 3D printing, stereolithography, and selective laser sintering, among others. These methods enable the creation of complex geometries and intricate designs that would be difficult or impossible to achieve with traditional manufacturing methods. By accelerating the development cycle, rapid prototyping helps companies stay competitive in a fast-paced industry, ensuring that new technologies and products can be brought to market more quickly and efficiently.

Stereolithogrphy Apparatus (SLA), Laminated Object Manufacturing (LOM), Selective Laser Sintering (SLS), Three Dimension Printing (3DP), Fused Depostion Modeling (FDM) in the Global Rapid Prototyping in Aerospace and Defense Market:

Stereolithography Apparatus (SLA) is one of the most widely used rapid prototyping techniques in the aerospace and defense market. It involves the use of a UV laser to cure and solidify thin layers of a photopolymer resin, building up a 3D model layer by layer. This method is known for its high precision and ability to produce smooth surface finishes, making it ideal for creating detailed prototypes and complex geometries. Laminated Object Manufacturing (LOM) is another technique that involves layering sheets of material, such as paper, plastic, or metal, which are bonded together using heat and pressure. The excess material is then cut away to reveal the final shape. LOM is particularly useful for creating large, bulky prototypes quickly and cost-effectively. Selective Laser Sintering (SLS) uses a high-powered laser to fuse small particles of plastic, metal, or ceramic powder into a solid structure. This technique is highly versatile and can produce durable, functional parts with complex geometries. Three Dimension Printing (3DP), commonly known as 3D printing, involves depositing material layer by layer to create a physical object from a digital model. This method is highly flexible and can use a wide range of materials, including plastics, metals, and ceramics. Fused Deposition Modeling (FDM) is another popular 3D printing technique that involves extruding thermoplastic material through a heated nozzle to build up a part layer by layer. FDM is known for its ease of use and ability to produce strong, durable parts. In the aerospace and defense market, these rapid prototyping techniques are used to create everything from small, intricate components to large, structural parts, enabling engineers to test and refine their designs quickly and efficiently.

Aerospace, Defense in the Global Rapid Prototyping in Aerospace and Defense Market:

In the aerospace sector, rapid prototyping is used extensively to develop and test new aircraft components and systems. Engineers can create scale models of wings, fuselages, and other critical parts to evaluate their performance in wind tunnel tests and other simulations. This allows for the identification and correction of potential issues early in the design process, reducing the risk of costly errors and delays. Rapid prototyping also enables the creation of custom tools and fixtures, which can be used to streamline the manufacturing process and improve overall efficiency. In the defense sector, rapid prototyping is used to develop and test new weapons systems, vehicles, and other equipment. Engineers can create detailed models of missiles, drones, and other complex systems to evaluate their performance and identify potential improvements. This allows for the rapid iteration and refinement of designs, ensuring that new technologies can be brought to market quickly and efficiently. Rapid prototyping also enables the creation of custom parts and components, which can be used to repair and maintain existing equipment, reducing downtime and improving overall readiness. In both the aerospace and defense sectors, rapid prototyping is a critical tool for innovation and development, enabling engineers to push the boundaries of what is possible and create new technologies that can meet the demands of a rapidly changing world.

Global Rapid Prototyping in Aerospace and Defense Market Outlook:

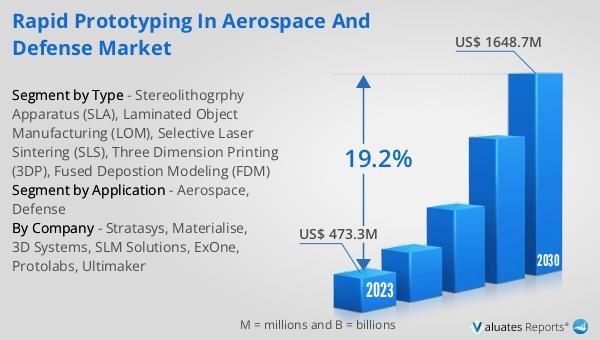

The global market for Rapid Prototyping in Aerospace and Defense was valued at $473.3 million in 2023 and is projected to grow significantly, reaching $1,648.7 million by 2030. This impressive growth is expected to occur at a compound annual growth rate (CAGR) of 19.2% during the forecast period from 2024 to 2030. This rapid expansion underscores the increasing importance of rapid prototyping technologies in these sectors. As aerospace and defense companies strive to innovate and stay ahead of the competition, the ability to quickly and efficiently develop and test new designs is becoming ever more critical. Rapid prototyping allows for the rapid iteration and refinement of ideas, reducing the time and cost associated with bringing new products to market. This growth also reflects the broader trend towards digital manufacturing and the increasing adoption of advanced technologies such as 3D printing, stereolithography, and selective laser sintering. As these technologies continue to evolve and improve, their applications in the aerospace and defense sectors are likely to expand, driving further growth in the market.

| Report Metric | Details |

| Report Name | Rapid Prototyping in Aerospace and Defense Market |

| Accounted market size in 2023 | US$ 473.3 million |

| Forecasted market size in 2030 | US$ 1648.7 million |

| CAGR | 19.2% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Stratasys, Materialise, 3D Systems, SLM Solutions, ExOne, Protolabs, Ultimaker |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |