What is Global Rapid Prototyping in Medical Market?

Global Rapid Prototyping in the Medical Market refers to the use of advanced manufacturing techniques to quickly create physical models or prototypes of medical devices, tools, and implants. This technology allows for the rapid development and testing of new medical products, significantly reducing the time and cost associated with traditional manufacturing methods. By using computer-aided design (CAD) and various 3D printing technologies, medical professionals and researchers can produce highly accurate and detailed models that can be used for a variety of purposes, including surgical planning, custom prosthetics, and educational tools. The ability to quickly iterate and refine designs based on real-world feedback is a significant advantage, enabling faster innovation and improved patient outcomes. As the demand for personalized and precise medical solutions continues to grow, the role of rapid prototyping in the medical market is becoming increasingly important. This technology not only enhances the efficiency of the development process but also opens up new possibilities for customized patient care and advanced medical research.

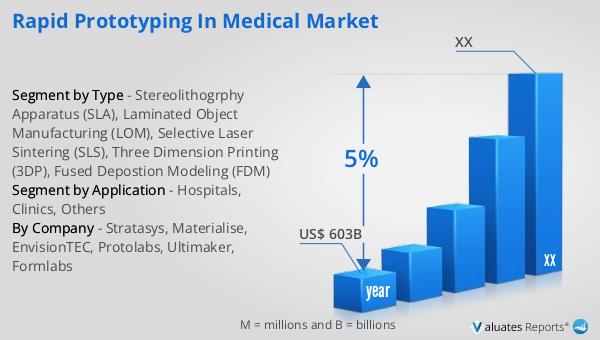

Stereolithogrphy Apparatus (SLA), Laminated Object Manufacturing (LOM), Selective Laser Sintering (SLS), Three Dimension Printing (3DP), Fused Depostion Modeling (FDM) in the Global Rapid Prototyping in Medical Market:

Stereolithography Apparatus (SLA) is one of the most widely used rapid prototyping technologies in the medical market. It works by using a laser to cure liquid resin into solid layers, building up a 3D model layer by layer. This method is highly accurate and can produce intricate details, making it ideal for creating detailed anatomical models and surgical guides. Laminated Object Manufacturing (LOM) involves layering sheets of material, such as paper or plastic, which are then cut and bonded together to form a 3D object. While not as precise as SLA, LOM is cost-effective and suitable for creating larger models. Selective Laser Sintering (SLS) uses a laser to fuse powdered materials, such as nylon or metal, into solid structures. This technique is particularly useful for creating durable and functional prototypes, including custom implants and prosthetics. Three Dimension Printing (3DP), commonly known as 3D printing, involves depositing material layer by layer to build a 3D object. This versatile technology can use a variety of materials, including plastics, metals, and ceramics, making it suitable for a wide range of medical applications. Fused Deposition Modeling (FDM) is another popular 3D printing method that extrudes thermoplastic material through a heated nozzle to create objects layer by layer. FDM is known for its ease of use and affordability, making it accessible for both large medical institutions and smaller clinics. Each of these rapid prototyping technologies offers unique advantages and can be selected based on the specific requirements of the medical application. By leveraging these advanced manufacturing techniques, the medical industry can accelerate the development of innovative solutions, improve patient care, and reduce costs.

Hospitals, Clinics, Others in the Global Rapid Prototyping in Medical Market:

The usage of Global Rapid Prototyping in the Medical Market spans various areas, including hospitals, clinics, and other healthcare settings. In hospitals, rapid prototyping is used to create patient-specific surgical guides and implants, which can significantly enhance the precision and outcomes of complex surgeries. Surgeons can use 3D-printed models to plan and practice procedures, reducing the risk of complications and improving patient safety. Additionally, hospitals can use rapid prototyping to produce custom prosthetics and orthotics, tailored to the unique anatomy of each patient, leading to better fit and comfort. In clinics, rapid prototyping is employed to develop and test new medical devices and tools. This technology allows for quick iteration and refinement of designs, enabling clinicians to bring innovative solutions to market faster. Clinics can also use 3D printing to create educational models for patient consultations, helping patients better understand their conditions and treatment options. Other healthcare settings, such as research institutions and educational facilities, benefit from rapid prototyping by using it to create detailed anatomical models for training and research purposes. These models can be used to simulate surgical procedures, study disease progression, and develop new treatment methods. The ability to produce accurate and detailed replicas of human anatomy enhances the learning experience for medical students and professionals, leading to improved skills and knowledge. Overall, the integration of rapid prototyping in various healthcare settings is transforming the way medical professionals approach patient care, research, and education, driving innovation and improving outcomes across the industry.

Global Rapid Prototyping in Medical Market Outlook:

According to our research, the global market for medical devices is projected to reach approximately US$ 603 billion in 2023, with an anticipated growth rate of 5% annually over the next six years. This significant market size underscores the increasing demand for advanced medical technologies and innovative solutions to address various healthcare challenges. The steady growth rate reflects the ongoing advancements in medical research, the rising prevalence of chronic diseases, and the growing need for personalized and precise medical treatments. As the medical device market continues to expand, rapid prototyping technologies are expected to play a crucial role in driving innovation and improving patient care. By enabling the quick development and testing of new medical devices, rapid prototyping helps manufacturers stay competitive and meet the evolving needs of healthcare providers and patients. The ability to produce customized and patient-specific solutions is particularly valuable in the medical field, where precision and accuracy are paramount. As a result, the adoption of rapid prototyping technologies is likely to increase, further fueling the growth of the global medical device market. This dynamic and evolving landscape presents numerous opportunities for medical professionals, researchers, and manufacturers to collaborate and develop cutting-edge solutions that enhance patient outcomes and advance the field of medicine.

| Report Metric | Details |

| Report Name | Rapid Prototyping in Medical Market |

| Accounted market size in year | US$ 603 billion |

| CAGR | 5% |

| Base Year | year |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Stratasys, Materialise, EnvisionTEC, Protolabs, Ultimaker, Formlabs |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |