What is Global Industrial Internal Grinding Machines Market?

The Global Industrial Internal Grinding Machines Market refers to the worldwide industry focused on the production and sale of machines designed for internal grinding processes. These machines are essential in manufacturing and engineering sectors, where precision and accuracy are paramount. Internal grinding machines are used to finish the internal surfaces of cylindrical or conical workpieces, ensuring they meet exact specifications. This market encompasses a variety of machine types, including standard internal grinders, planetary internal grinders, and centerless internal grinders, each catering to different industrial needs. The market's growth is driven by increasing demand for high-precision components in industries such as automotive, aerospace, and industrial machinery. Technological advancements and the need for efficient production processes also contribute to the market's expansion. As industries continue to evolve and require more sophisticated machinery, the Global Industrial Internal Grinding Machines Market is expected to see sustained growth, reflecting its critical role in modern manufacturing.

Standard Internal Grinder, Planetary Internal Grinder, Centerless Internal Grinder in the Global Industrial Internal Grinding Machines Market:

Standard internal grinders, planetary internal grinders, and centerless internal grinders are three primary types of machines within the Global Industrial Internal Grinding Machines Market, each serving unique functions. Standard internal grinders are the most common type, designed to grind the internal surfaces of cylindrical or conical workpieces. These machines are highly versatile and can handle a wide range of materials, making them suitable for various applications. They typically feature a rotating spindle that holds the grinding wheel, which is then fed into the workpiece to achieve the desired finish. Planetary internal grinders, on the other hand, are specialized machines that use a planetary motion to grind the internal surfaces. This type of grinder is particularly useful for achieving high precision and fine finishes, as the planetary motion allows for more controlled and consistent grinding. The grinding wheel in a planetary internal grinder rotates around its own axis while simultaneously orbiting around the workpiece, ensuring even material removal and reducing the risk of defects. Centerless internal grinders are unique in that they do not use a spindle to hold the workpiece. Instead, the workpiece is supported by a blade and rotated by a regulating wheel, while the grinding wheel removes material from the internal surface. This design allows for continuous grinding of multiple workpieces, making centerless internal grinders highly efficient for high-volume production. Each of these machines plays a crucial role in the Global Industrial Internal Grinding Machines Market, catering to different industrial needs and contributing to the overall growth and development of the market.

Automotive, Aerospace, Industrial Machinery, Others in the Global Industrial Internal Grinding Machines Market:

The usage of Global Industrial Internal Grinding Machines Market spans across various industries, including automotive, aerospace, industrial machinery, and others. In the automotive industry, internal grinding machines are essential for manufacturing high-precision components such as engine cylinders, transmission gears, and fuel injectors. These components require exact specifications to ensure optimal performance and efficiency, making internal grinding machines indispensable in the production process. The aerospace industry also relies heavily on internal grinding machines for the production of critical components such as turbine blades, landing gear parts, and hydraulic systems. The high precision and accuracy provided by these machines are crucial for ensuring the safety and reliability of aerospace components, which must withstand extreme conditions and rigorous performance standards. In the industrial machinery sector, internal grinding machines are used to manufacture a wide range of components, including bearings, shafts, and gears. These components are integral to the operation of various types of machinery, and their quality directly impacts the performance and longevity of the equipment. Internal grinding machines enable manufacturers to produce components with tight tolerances and fine finishes, ensuring the smooth operation of industrial machinery. Other industries, such as medical device manufacturing and tool and die making, also benefit from the capabilities of internal grinding machines. In medical device manufacturing, for example, internal grinding machines are used to produce components for surgical instruments and implants, which require high precision and biocompatibility. In tool and die making, these machines are used to create molds and dies with intricate internal geometries, enabling the production of complex parts with high accuracy. Overall, the Global Industrial Internal Grinding Machines Market plays a vital role in supporting the manufacturing needs of various industries, driving innovation and ensuring the production of high-quality components.

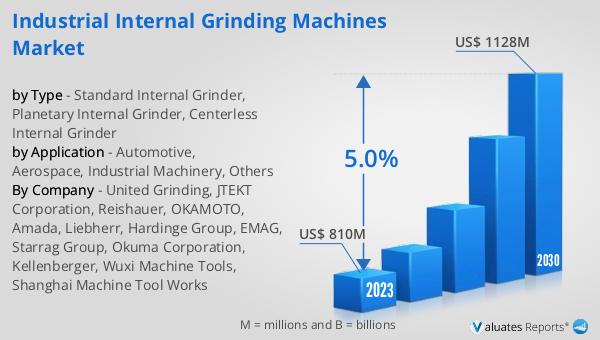

Global Industrial Internal Grinding Machines Market Outlook:

The global Industrial Internal Grinding Machines market was valued at US$ 810 million in 2023 and is anticipated to reach US$ 1128 million by 2030, witnessing a CAGR of 5.0% during the forecast period 2024-2030. This market outlook highlights the significant growth potential of the industry, driven by increasing demand for high-precision components across various sectors. The projected growth reflects the importance of internal grinding machines in modern manufacturing processes, where precision and efficiency are paramount. As industries continue to evolve and require more sophisticated machinery, the demand for internal grinding machines is expected to rise, contributing to the market's expansion. The anticipated growth also underscores the ongoing advancements in grinding technology, which are enabling manufacturers to achieve higher levels of precision and productivity. With a compound annual growth rate (CAGR) of 5.0%, the market is set to experience steady growth, driven by the need for high-quality components in industries such as automotive, aerospace, and industrial machinery. This positive outlook indicates a promising future for the Global Industrial Internal Grinding Machines Market, as it continues to play a crucial role in supporting the manufacturing needs of various industries.

| Report Metric | Details |

| Report Name | Industrial Internal Grinding Machines Market |

| Accounted market size in 2023 | US$ 810 million |

| Forecasted market size in 2030 | US$ 1128 million |

| CAGR | 5.0% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | United Grinding, JTEKT Corporation, Reishauer, OKAMOTO, Amada, Liebherr, Hardinge Group, EMAG, Starrag Group, Okuma Corporation, Kellenberger, Wuxi Machine Tools, Shanghai Machine Tool Works |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |