What is Global Modular Sterile Isolator Market?

The Global Modular Sterile Isolator Market refers to the industry focused on the production and distribution of modular sterile isolators. These isolators are specialized equipment designed to create a controlled, sterile environment for various applications, primarily in the healthcare and pharmaceutical sectors. They are essential for processes that require a contamination-free setting, such as the preparation of sterile medications, research involving sensitive biological materials, and the handling of hazardous substances. The modular nature of these isolators means they can be customized and scaled according to specific needs, making them versatile and adaptable to different settings. This market is driven by the increasing demand for sterile environments in medical and pharmaceutical applications, advancements in isolator technology, and stringent regulatory requirements for contamination control. As healthcare and pharmaceutical industries continue to grow and evolve, the need for reliable and efficient sterile isolators is expected to rise, making this market a critical component of modern medical and scientific infrastructure.

Class II, Class III, Others in the Global Modular Sterile Isolator Market:

Class II and Class III isolators, along with other types, play distinct roles within the Global Modular Sterile Isolator Market. Class II isolators are designed to provide a sterile environment for the handling of non-hazardous materials. They are commonly used in applications where product protection is paramount, such as in the preparation of sterile medications and the handling of sensitive biological samples. These isolators typically feature a controlled airflow system that ensures a contamination-free environment, making them ideal for pharmaceutical compounding and laboratory research. On the other hand, Class III isolators are designed for the handling of hazardous materials. They provide a higher level of protection for both the product and the operator, making them suitable for applications involving toxic or infectious substances. These isolators are often used in biosafety laboratories and for the preparation of hazardous drugs. They feature a completely sealed environment with robust filtration systems to prevent any escape of contaminants. Other types of isolators in this market include flexible film isolators and rigid isolators. Flexible film isolators are lightweight and portable, making them ideal for temporary or mobile applications. They are often used in field research or in situations where a permanent installation is not feasible. Rigid isolators, on the other hand, are more durable and provide a higher level of protection. They are commonly used in permanent installations in hospitals, pharmaceutical manufacturing facilities, and research laboratories. Each type of isolator has its own unique features and applications, making the Global Modular Sterile Isolator Market a diverse and dynamic industry. The choice of isolator depends on the specific needs of the application, including the level of protection required, the type of materials being handled, and the operational environment. As technology continues to advance, the capabilities and applications of these isolators are expected to expand, further driving the growth of this market.

Hospital, Pharmaceutical, Laboratory, Others in the Global Modular Sterile Isolator Market:

The usage of Global Modular Sterile Isolator Market spans across various sectors, including hospitals, pharmaceutical companies, laboratories, and other specialized fields. In hospitals, these isolators are crucial for maintaining sterile environments during the preparation of medications, particularly those that are administered intravenously. They help prevent contamination, ensuring that patients receive safe and effective treatments. Additionally, sterile isolators are used in hospital pharmacies for compounding sterile preparations, such as chemotherapy drugs, which require a contamination-free environment to ensure patient safety. In the pharmaceutical industry, modular sterile isolators are essential for the production of sterile drugs and biologics. They provide a controlled environment that meets stringent regulatory requirements for contamination control, ensuring the safety and efficacy of pharmaceutical products. These isolators are used in various stages of drug production, including formulation, filling, and packaging. They are also used in research and development laboratories for the handling of sensitive biological materials and the preparation of experimental drugs. Laboratories, both academic and commercial, also rely on modular sterile isolators for a variety of applications. In research laboratories, these isolators are used to handle and study sensitive biological samples, such as cell cultures and microorganisms, in a contamination-free environment. They are also used in diagnostic laboratories for the preparation of samples and reagents, ensuring the accuracy and reliability of test results. Other specialized fields that use modular sterile isolators include biotechnology, food and beverage production, and cosmetics manufacturing. In biotechnology, these isolators are used for the production of biologics and other sensitive products that require a sterile environment. In the food and beverage industry, they are used for the preparation of sterile ingredients and the packaging of products to ensure safety and quality. In cosmetics manufacturing, sterile isolators are used to produce and package products that require a contamination-free environment, such as sterile creams and lotions. Overall, the versatility and adaptability of modular sterile isolators make them indispensable in a wide range of applications, driving the growth and development of the Global Modular Sterile Isolator Market.

Global Modular Sterile Isolator Market Outlook:

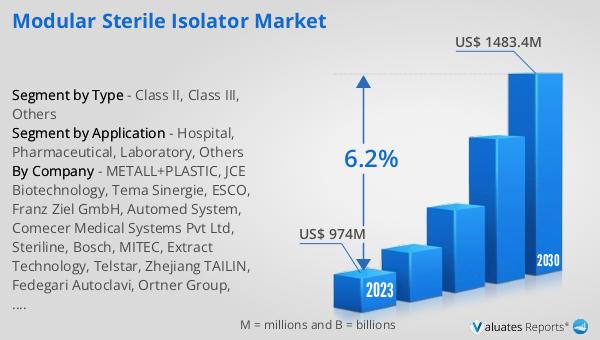

The global Modular Sterile Isolator market was valued at US$ 974 million in 2023 and is anticipated to reach US$ 1483.4 million by 2030, witnessing a CAGR of 6.2% during the forecast period 2024-2030. This market outlook highlights the significant growth potential of the modular sterile isolator market over the next several years. The increasing demand for sterile environments in various industries, including healthcare, pharmaceuticals, and biotechnology, is driving this growth. The market's valuation of US$ 974 million in 2023 underscores its current importance and widespread adoption. As industries continue to prioritize contamination control and regulatory compliance, the demand for advanced sterile isolators is expected to rise. The projected market value of US$ 1483.4 million by 2030 reflects the ongoing advancements in isolator technology and the expanding applications of these systems. The compound annual growth rate (CAGR) of 6.2% indicates a steady and robust growth trajectory, driven by factors such as technological innovations, increasing healthcare needs, and stringent regulatory requirements. This market outlook provides valuable insights into the future trends and opportunities in the Global Modular Sterile Isolator Market, emphasizing its critical role in ensuring sterile and contamination-free environments across various sectors.

| Report Metric | Details |

| Report Name | Modular Sterile Isolator Market |

| Accounted market size in 2023 | US$ 974 million |

| Forecasted market size in 2030 | US$ 1483.4 million |

| CAGR | 6.2% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | METALL+PLASTIC, JCE Biotechnology, Tema Sinergie, ESCO, Franz Ziel GmbH, Automed System, Comecer Medical Systems Pvt Ltd, Steriline, Bosch, MITEC, Extract Technology, Telstar, Zhejiang TAILIN, Fedegari Autoclavi, Ortner Group, Getinge, SHIBUYA CORPORATION, SKAN |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |