What is Global Plastic Compound Extruder Market?

The Global Plastic Compound Extruder Market is a specialized segment within the broader plastic processing industry. This market focuses on the machinery used to mix and shape plastic compounds into various forms. Extruders are the primary machines in this market, and they work by forcing plastic material through a shaped die to create continuous shapes like pipes, profiles, and sheets. The market encompasses a wide range of extruders, including single screw and twin screw models, each designed for specific applications and material types. These machines are essential in producing high-quality plastic products used in numerous industries, from automotive to construction. The global demand for plastic compound extruders is driven by the increasing need for efficient and cost-effective plastic processing solutions. As industries continue to innovate and develop new plastic materials, the role of extruders becomes even more critical in ensuring consistent quality and performance. The market is characterized by technological advancements, with manufacturers continually improving extruder designs to enhance productivity, energy efficiency, and product quality. Overall, the Global Plastic Compound Extruder Market plays a vital role in the modern manufacturing landscape, supporting the production of a wide array of plastic products that are integral to everyday life.

Single Screw Extruder, Twin Screw Extruder in the Global Plastic Compound Extruder Market:

Single screw extruders and twin screw extruders are two primary types of machines used in the Global Plastic Compound Extruder Market, each with distinct features and applications. Single screw extruders are the most common type and are known for their simplicity and cost-effectiveness. They consist of a single rotating screw within a heated barrel, which melts and pushes the plastic material through a die to form the desired shape. These extruders are ideal for applications where the material does not require extensive mixing or compounding, such as in the production of pipes, profiles, and simple sheets. Single screw extruders are favored for their straightforward operation, lower maintenance costs, and suitability for a wide range of materials, including polyethylene, polypropylene, and PVC. On the other hand, twin screw extruders feature two intermeshing screws that rotate within a heated barrel. This design allows for more intensive mixing and compounding of materials, making twin screw extruders ideal for applications that require precise control over the material properties. They are commonly used in the production of complex plastic compounds, masterbatches, and specialty materials that require uniform dispersion of additives, fillers, and colorants. Twin screw extruders offer greater flexibility and control over the extrusion process, enabling manufacturers to produce high-quality, customized plastic products. Despite their higher initial cost and more complex operation, twin screw extruders are preferred in industries where product quality and consistency are paramount. Both single screw and twin screw extruders play crucial roles in the Global Plastic Compound Extruder Market, catering to different needs and applications. The choice between the two depends on factors such as the type of material being processed, the desired properties of the final product, and the specific requirements of the manufacturing process. As the market continues to evolve, advancements in extruder technology are expected to further enhance the capabilities and efficiency of both single screw and twin screw extruders, driving innovation and growth in the plastic processing industry.

Profile Extrusion, Pipe Extrusion, Pellets Extrusion, Others in the Global Plastic Compound Extruder Market:

The Global Plastic Compound Extruder Market finds extensive usage in various applications, including profile extrusion, pipe extrusion, pellets extrusion, and others. Profile extrusion involves the production of continuous shapes with a consistent cross-section, such as window frames, door profiles, and automotive trim. Extruders used in profile extrusion must ensure precise control over the shape and dimensions of the final product, making them essential for industries that require high-quality, custom-designed plastic profiles. Pipe extrusion, another significant application, involves the production of plastic pipes used in plumbing, irrigation, and industrial applications. The extruders used in this process must be capable of producing pipes with uniform wall thickness and diameter, ensuring durability and performance. Pipe extrusion is a critical application in the construction and infrastructure sectors, where reliable and cost-effective piping solutions are in high demand. Pellets extrusion, on the other hand, involves the production of plastic pellets or granules, which serve as raw materials for various plastic manufacturing processes. These pellets are produced by extruding molten plastic through a die and then cutting it into small, uniform pieces. Pellets extrusion is essential for producing high-quality plastic compounds that can be easily transported, stored, and processed into final products. This application is particularly important in the production of masterbatches, where precise control over the composition and properties of the plastic material is required. Other applications of plastic compound extruders include the production of films, sheets, and coatings, which are used in packaging, automotive, and consumer goods industries. These applications require extruders that can produce thin, uniform layers of plastic with consistent properties, ensuring the quality and performance of the final products. Overall, the Global Plastic Compound Extruder Market plays a vital role in supporting a wide range of industries by providing efficient and reliable solutions for plastic processing. The versatility and adaptability of extruders make them indispensable in the production of high-quality plastic products that meet the diverse needs of modern manufacturing.

Global Plastic Compound Extruder Market Outlook:

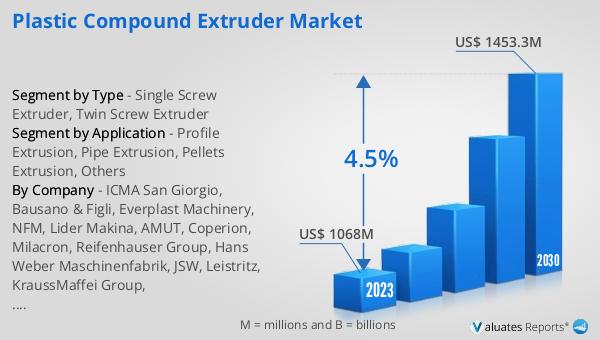

The global Plastic Compound Extruder market was valued at US$ 1068 million in 2023 and is anticipated to reach US$ 1453.3 million by 2030, witnessing a CAGR of 4.5% during the forecast period 2024-2030. This market outlook highlights the steady growth and increasing demand for plastic compound extruders across various industries. The projected growth rate indicates a positive trend, driven by factors such as technological advancements, rising demand for plastic products, and the need for efficient and cost-effective plastic processing solutions. As industries continue to innovate and develop new plastic materials, the role of extruders becomes even more critical in ensuring consistent quality and performance. The market's growth is also supported by the increasing adoption of plastic products in sectors such as automotive, construction, packaging, and consumer goods. These industries rely on high-quality plastic compounds to meet their specific requirements, driving the demand for advanced extruder technologies. Additionally, the focus on sustainability and environmental concerns has led to the development of eco-friendly plastic compounds, further boosting the market for plastic compound extruders. Overall, the Global Plastic Compound Extruder Market is poised for significant growth, reflecting the ongoing advancements and increasing demand for efficient plastic processing solutions.

| Report Metric | Details |

| Report Name | Plastic Compound Extruder Market |

| Accounted market size in 2023 | US$ 1068 million |

| Forecasted market size in 2030 | US$ 1453.3 million |

| CAGR | 4.5% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | ICMA San Giorgio, Bausano & Figli, Everplast Machinery, NFM, Lider Makina, AMUT, Coperion, Milacron, Reifenhauser Group, Hans Weber Maschinenfabrik, JSW, Leistritz, KraussMaffei Group, Battenfeld-Cincinnati, Colsite Group, CPM Extrusion Group, Davis-Standard |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |